Inconel X-750 Plate

Home » Inconel X-750 Plate

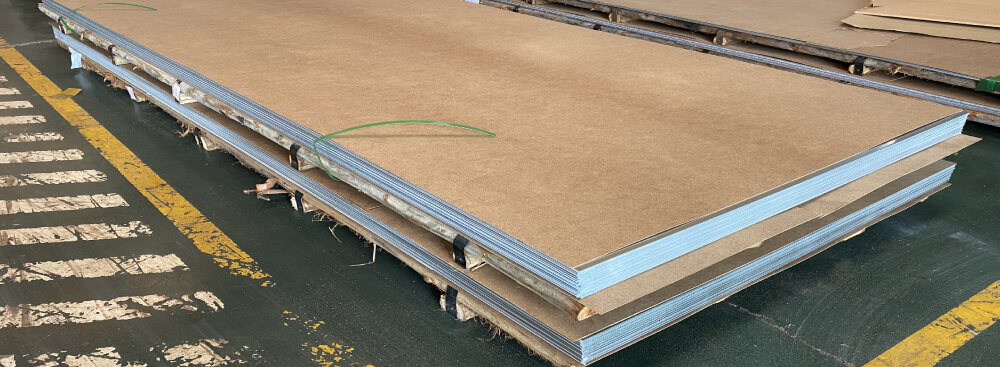

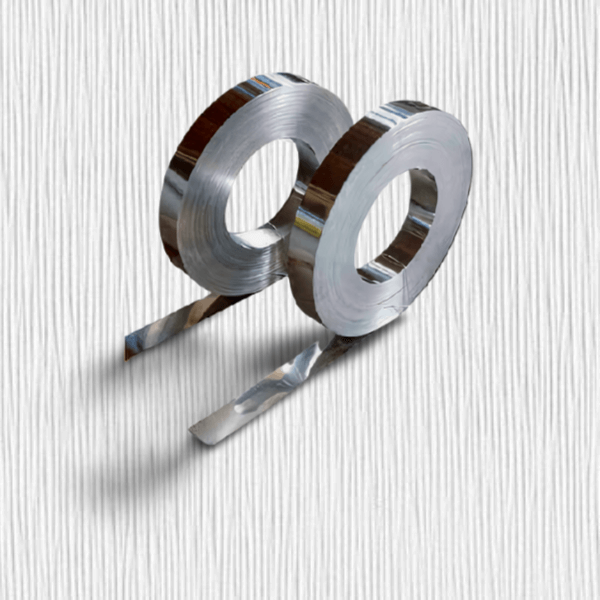

UNS N07750 Plain Sheet, DIN 2.4669 Hot Rolled Sheet, ASTM B670 Inconel X-750 2B Finish, DIN 2.4669 Clad Plate, UNS N07750 Ring, ASME SB670 Inconel X-750 Flats, ASTM B670 Inconel X-750 CR Sheet, ASTM B670 Inconel X-750 Sheets, UNS N07750 Circle, ASTM B637 Inconel X-750 Perforated Sheets, ASME SB670 Inconel X-750 Rolls.

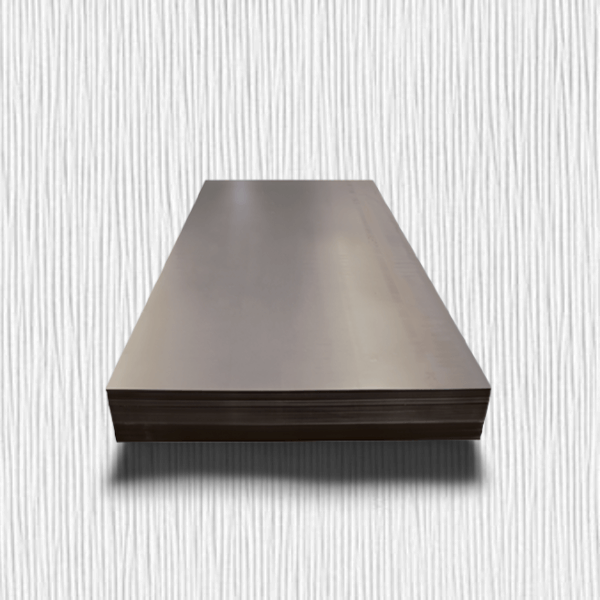

Inconel X-750 is a nickel-chromium alloy plate used in high-heat applications. It keeps strength even in a heated environment. The plate can handle heat up to 1300 degrees Fahrenheit. It does not melt or deform easily.

The plate has good resistance to corrosion and oxidation. This means it does not rust or wear down quickly. Oxidation resistance is important in heat. Oxidation can damage metals over time. Inconel X-750 stands up to oxidation and lasts a long time.

The plate has high tensile strength. This means it resists forces that try to pull it apart or stretch it. It also has good fatigue strength. That means it can flex repeatedly without breaking. Even after bending back and forth, it stays strong.

UNS N07750 Plate contains nickel, chromium, iron, niobium, aluminum, and titanium. Small amounts of carbon and manganese are also added. The percentages can be adjusted to modify the properties. More chromium improves oxidation and corrosion resistance. More aluminum increases strength at lower temperatures.

The plate is forged and annealed for strength. It is heated, pressed, and cooled slowly to improve the internal grain structure. This makes the metal more durable overall.

The ASTM B670 Inconel X-750 Shims has many applications in hot environments. It is used for industrial furnace parts. It makes combustion cans and liners. These contain and channel hot gases. The plate is also used for high-pressure valves and casings. Other uses are in chemical plants and jet engines. Anywhere temperatures exceed 1200 degrees F, this alloy stands up well.

With its high heat and corrosion resistance, the Inconel X-750 plate lasts in demanding conditions. Good tensile and fatigue strength ensure durability even with repeated stress. Adjustable alloy mixtures provide ideal properties. Forging improves the internal grain structure. With this combination of strength, longevity, and fabrication options, the Inconel X-750 serves critical roles in hot environments. It resists wear over time and provides reliable performance.

Specification Of Inconel X-750 Plate

| Specifications | ASTM B670 / ASME SB670 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

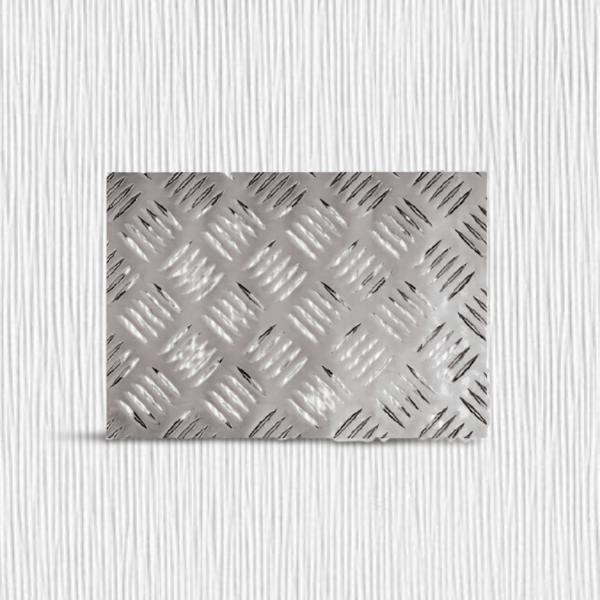

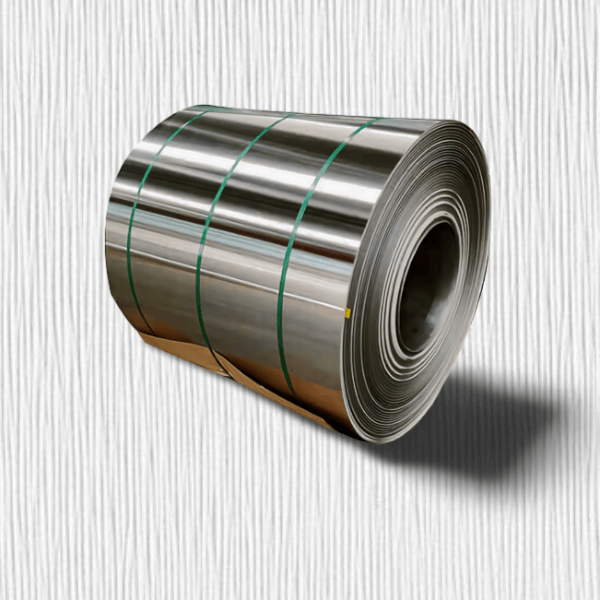

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Inconel X-750 Plate

-

ASTM B670 Inconel X-750 2B Finish US $47 - $50 / Kg

-

ASME SB670 Inconel X-750 Coil US $44 - $50 / Kg

-

UNS N07750 Circle US $44 - $46 / Kg

-

DIN 2.4669 Clad Plate US $45 - $49 / Kg

-

ASTM B670 Inconel X-750 CR Sheet US $46 - $47 / Kg

Equivalent Grades Of Inconel X-750 Plate

| STANDARD | UNS | WNR. |

| Inconel X-750 | N07750 | 2.4669 |

Chemical Composition Of Inconel X-750 Plate

| Al | C | Cr | Co | Cu | Fe | Mn | Nb | Ni | Ti | S | Si |

| 0.40-1.0 | .08 max | 14.0-17.0 | 1.00 max | 0.50 max | 5.0-9.0 | 1.00 max | 0.70-1.20 | 70.0 min | 2.25-2.75 | .01 max | .50 max |

Mechanical Properties Of Inconel X-750 Plate

| Ultimate Tensile Strength | .2% Yield Strength | Elongation % |

| 1250 MPa, 181000 psi | 850 MPa, 123000 psi | 30 |

Different Types Of Inconel X-750 Plate

Our Manufacturing Process Of Inconel X-750 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Plate

Our Material

Contact Us

Supplying World Wide