Inconel 601 Plate

Home » Inconel 601 Plate

ASTM B168 Inconel 601 Sheets, UNS N06601 Ring, ASME SB168 Inconel 601 Plate, UNS N06601 Foil Sheet, ASTM B168 Inconel 601 2B Finish, UNS N06601 Circle, DIN 2.4851 Shims, ASTM B168 Inconel 601 CR Sheet.

Inconel 601 is a nickel-chromium alloy plate that is known for its strength and resistance to heat and corrosion. This makes it useful for many high-temperature applications.

The main things that make ASTM B168 Inconel 601 Shims good are its properties. It has high tensile strength even at very hot temperatures. Tensile strength means it resists being pulled apart. Inconel 601 keeps its strength up to 2,000 degrees Fahrenheit. It also stands up to oxidation and corrosion. Oxidation means it does not react with oxygen. Corrosion means it does not react with other chemicals. This material does not rust or degrade easily.

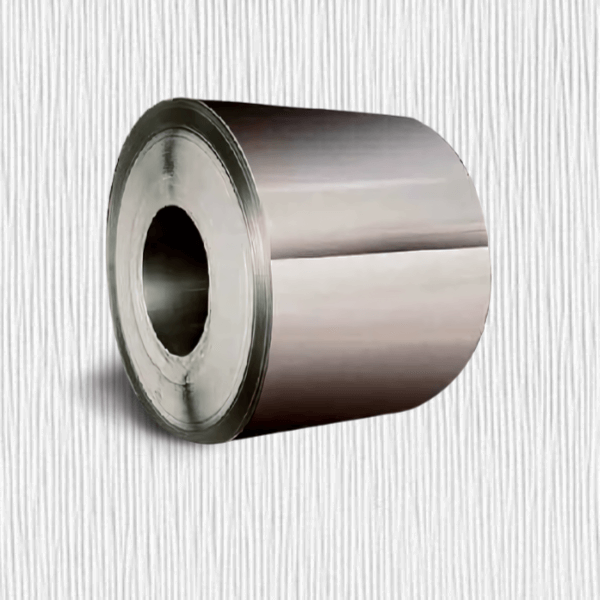

ASME SB168 Inconel 601 Slitting Coil gets its properties from its mixture of nickel, chromium, iron, and small amounts of other elements. The nickel gives it strength and ductility at high temps. Ductility means it can be shaped and worked. The chromium helps it resist oxidation and corrosion.

This alloy is used for parts that need to handle extreme heat. An example is furnace components. It can withstand the high temperatures inside furnaces without losing strength or corroding. ASME SB168 Inconel 601 Hot Rolled Sheet is also good for heat-treating equipment. Heat treating is a process that uses precise heating and cooling to create certain properties in metals. The alloy resists scaling and distortion at the high heat needed for heat treatment.

Other uses include annealers, reformers, and breaching nozzles. Annealers heat up metal products to make them softer and more workable. Reformers use heat and steam to refine chemicals. Breaching nozzles guide hot discharged gas.

Inconel 601 alloy plate has valuable properties that make it perfect for extreme temperature situations. Its blend of metals gives it strength, corrosion resistance and high-temperature ability. Industries like heat treating, chemical processing and power generation rely on it for durable parts. This material stands up to conditions that would damage other metals.

Specification Of Inconel 601 Plate

| Specifications | ASTM B168 / ASME SB168 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Inconel 601 Plate

-

ASTM B168 Inconel 601 2B Finish US $44 - $50 / Kg

-

ASME SB168 Inconel 601 Coil US $46 - $47 / Kg

-

UNS N06601 Circle US $44 - $46 / Kg

-

DIN 2.4851 Clad Plate US $47 - $50 / Kg

-

ASTM B168 Inconel 601 CR Sheet US $45 - $49 / Kg

Equivalent Grades Of Inconel 601 Plate

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 601 | N06601 | 2.4851 | NiCr23Fe | NiCr15Fe | NCF 601 | NA 49 | XH60BT | ЭИ868 |

Chemical Composition Of Inconel 601 Plate

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Mechanical Properties Of Inconel 601 Plate

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Different Types Of Inconel 601 Plate

Our Manufacturing Process Of Inconel 601 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Plate

Our Material

Contact Us

Supplying World Wide