Inconel 617 Plate

Home » Inconel 617 Plate

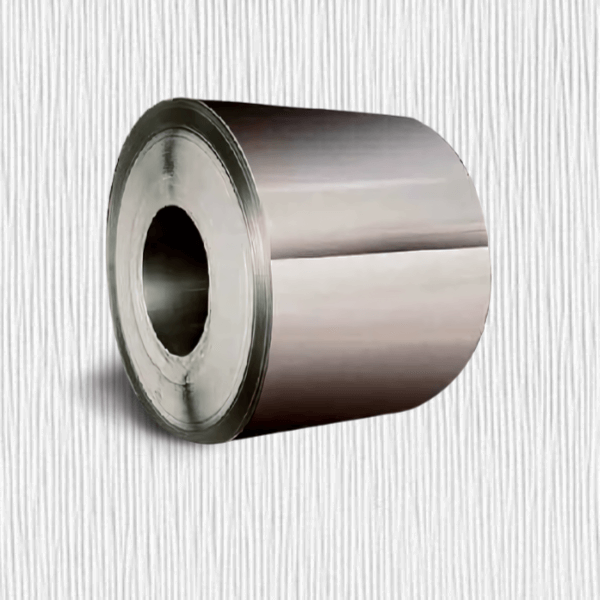

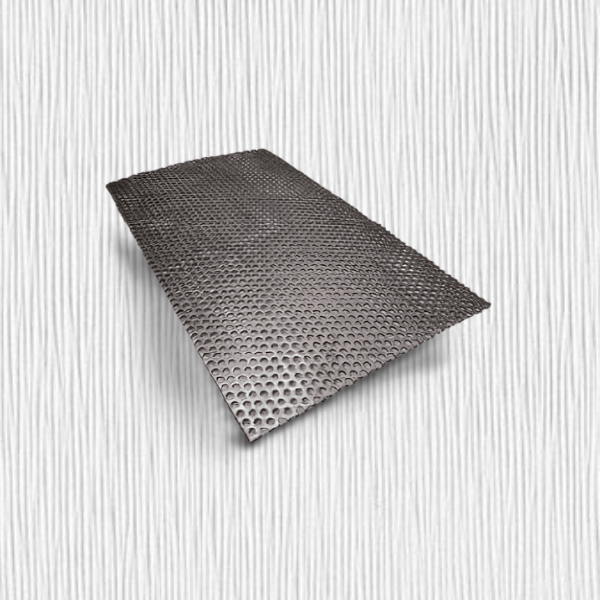

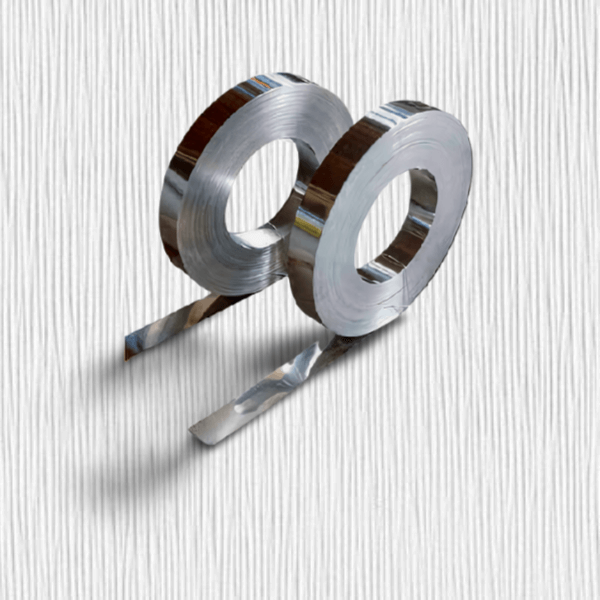

ASTM B168 Inconel 617 2B Finish, UNS N06617 Plain Sheet, ASME SB168 Inconel 617 Rolls, ASME SB168 Inconel 617 Coil, UNS N06617 Ring, UNS N06617 Foil Sheet, ASTM B168 Inconel 617 Perforated Sheets.

Inconel 617 is a nickel-chromium-cobalt alloy plate that offers high-temperature strength and corrosion resistance. This superalloy plate is an ideal choice for applications that involve prolonged exposure to extreme environments.

The alloy composition of the Inconel 617 plate includes nickel, chromium, cobalt, molybdenum, aluminium, and small amounts of other elements. This carefully balanced chemical makeup gives the metal outstanding heat resistance and durability.

DIN 2.4663 CR Sheet has excellent mechanical properties at both cryogenic and high temperatures. It maintains good tensile, fatigue, and creep rupture strength up to 1300°F (700°C). The alloy also retains ductility and toughness at high and low temperatures.

The plate has exceptional corrosion and oxidation resistance. It can withstand corrosive effects in many acids, alkalis, salts, and more. A tightly adherent oxide film protects the surface at high temperatures. This is stable in many atmospheres with very low oxygen levels.

The combination of thermal properties, corrosion resistance, and fabricability of the ASTM B168 Inconel 617 Diamond Plate makes it suitable for demanding heat-transfer applications. It is primarily used in heat exchanger tubing for gas turbine engines. The alloy allows thinner tube walls and improves efficiency.

Chemical processing industries rely on Inconel 617 for heat exchangers, reaction vessels, distillation columns, and piping. It withstands corrosive fluids and high temperatures in petroleum refining, pulp and paper production, and other processes. The plate resists stress corrosion cracking in hot, alkaline environments.

Inconel 617 sees nuclear service for core components and steam generators. Its neutron absorption is relatively low compared to other alloys. Excellent creep rupture strength up to 1500°F (815°C) suits the plate for nuclear reactor internals. It also performs well for liquefied natural gas storage and transportation.

For plate forming, the alloy should be annealed and rapidly air-cooled to restore ductility. It can be forged or otherwise hot worked between 1950-2150°F (1065-1175°C). Inconel 617 welds are well-using gas tungsten arc welding or shielded metal arc welding. Appropriate filler rods match the plate composition.

Specification Of Inconel 617 Plate

| Specifications | ASTM B168 / ASME SB168 |

| Dimensional specification | ASTM, ASME and API |

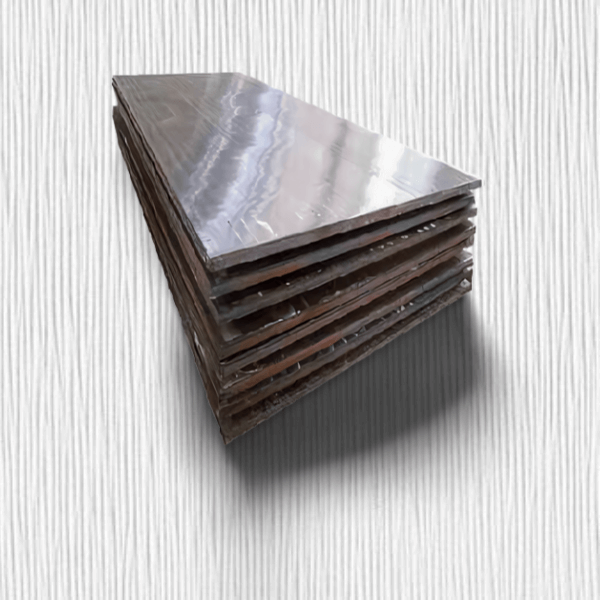

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Inconel 617 Plate

-

ASTM B168 Inconel 617 2B Finish US $47 - $50 / Kg

-

ASME SB168 Inconel 617 Coil US $44 - $50 / Kg

-

UNS N06617 Circle US $44 - $46 / Kg

-

DIN 2.4663 Clad Plate US $45 - $49 / Kg

-

ASTM B168 Inconel 617 CR Sheet US $46 - $47 / Kg

Equivalent Grades Of Inconel 617 Plate

| STANDARD | UNS | WNR. |

| Alloy 617 | N06617 | 2.4663 |

Chemical Composition Of Inconel 617 Plate

| C | Mn | S | Si | Cr | Mo | Ni | Cu | Ti | Al | B | Co | Fe |

| 0.05-0.15 | 1.0 Max | 0.015 Max | 1.0 Max | 20.0-24.0 | 8.0-10.0 | 44.5 Min | 0.5 Max | 0.6 Max | 0.8-1.5 | 0.006 Max | 10.0-15.0 | 3.0 Max |

Mechanical Properties Of Inconel 617 Plate

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Different Types Of Inconel 617 Plate

Our Manufacturing Process Of Inconel 617 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Plate

Our Material

Contact Us

Supplying World Wide