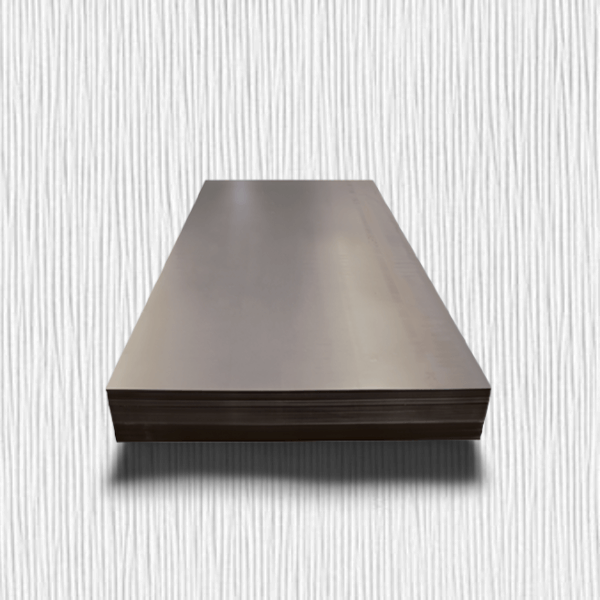

Inconel 625 Plate

Home » Inconel 625 Plate

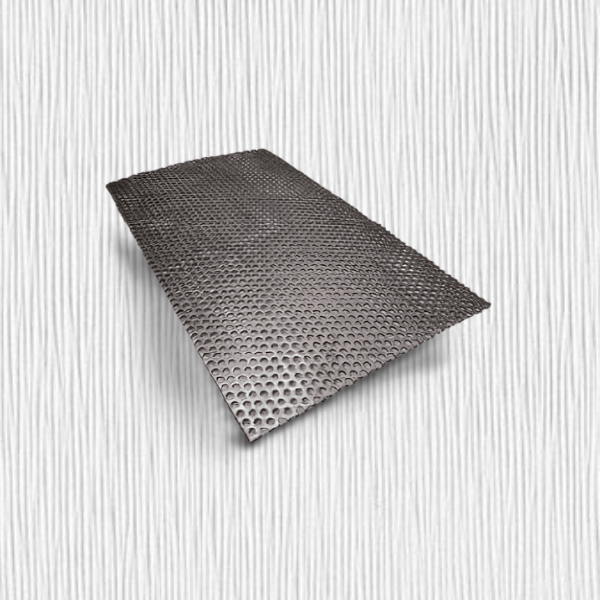

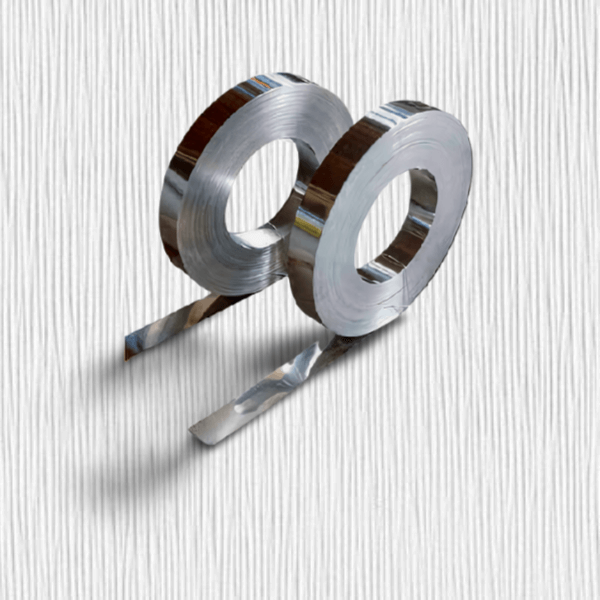

ASTM B443 Inconel 625 2B Finish, DIN 2.4856 Clad Plate, DIN 2.4856 Hot Rolled Sheet, ASTM B443 Inconel 625 Sheets, UNS N06625 Plain Sheet, ASTM B443 Inconel 625 CR Sheet, ASTM B443 Inconel 625 Perforated Sheets, UNS N06625 Foil Sheet, DIN 2.4856 Shims, UNS N06625 Circle, ASME SB443 Inconel 625 Plate.

Inconel 625 is a nickel-chromium alloy plate known for its strength, corrosion resistance, and fabrication ease. The main elements composing this nickel-based superalloy plate are nickel, chromium, molybdenum, niobium, and iron. The nickel and chromium content gives Inconel good oxidation and corrosion resistance.

The plate has remarkable tensional, creep and rupture properties in extreme temperatures. It keeps strength and toughness from cryogenic temperatures up to 1800°F. Inconel 625 has a good fatigue strength and resists cracking. The plate can be formed and welded conveniently using the usual methods. It has good welding properties due to the composition of the alloy that hinders weld decay. The UNS N06625 Plain Sheet gives an unusual blend of strength, toughness and fabricability.

Inconel 625 plate is widely used in industries like aerospace, chemical processing, pollution control, and oil and gas. Components like engine exhaust manifolds, turbine blades, heat exchangers, and rocket motor casings rely on their strength at high temperatures. The petrochemical industry utilizes Inconel 625 for its resistance to pitting and stress corrosion cracking.

The plate’s corrosion resistance makes it ideal for handling acidic gases and oxidizing environments. UNS N06625 Circle resists the effects of seawater, brine, and industrial pollution. Architectural cladding, food processing equipment, nuclear reactors, and surgical implants employ the plate where durability and biocompatibility are vital.

ASME SB443 Inconel 625 Plate provides ruggedness and longevity across challenging operating conditions. Parts maintain integrity when subjected to repeated heating and cooling cycles. The plate has twice the life expectancy of austenitic stainless steel.

Inconel 625 is a nickel-chromium alloy plate offering exceptional tensile strength, corrosion and oxidation resistance, and ease of fabrication. Inconel 625 plate delivers unparalleled performance where reliability at extreme temperatures and in corrosive environments is critical.

Specification Of Inconel 625 Plate

| Specifications | ASTM B443 / ASME SB443 |

| Dimensional specification | ASTM, ASME and API |

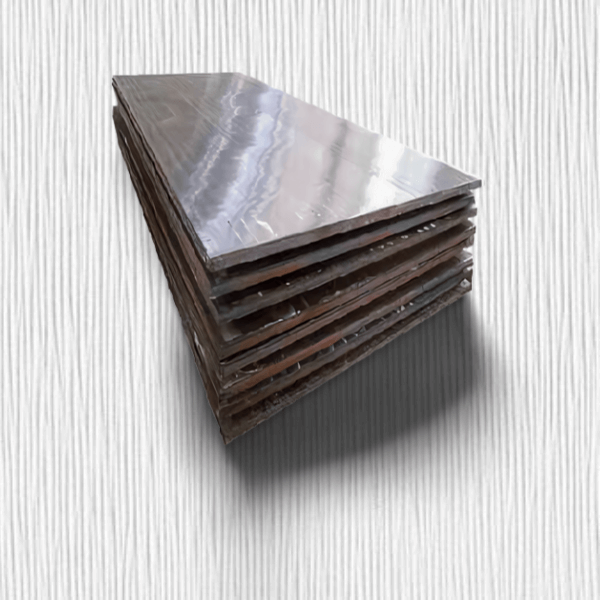

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

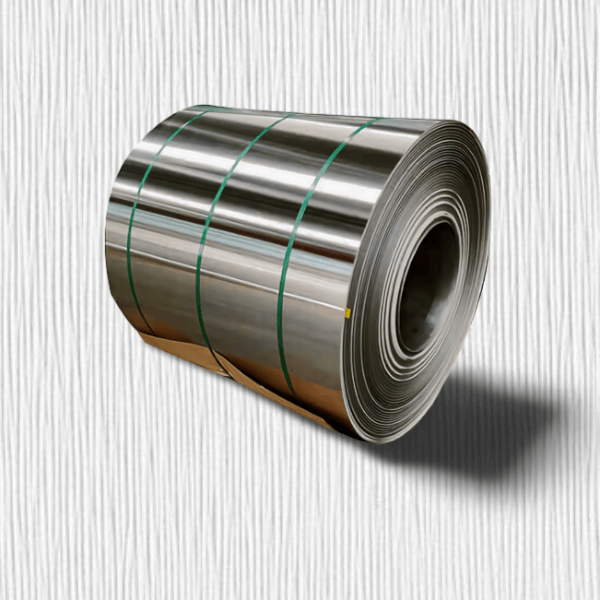

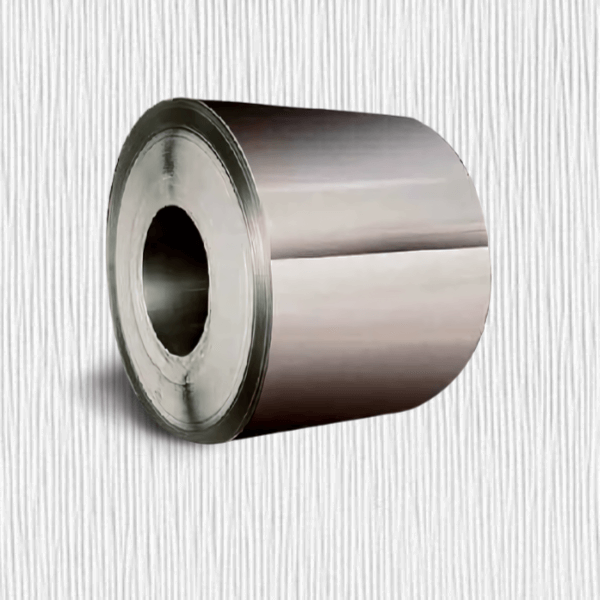

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

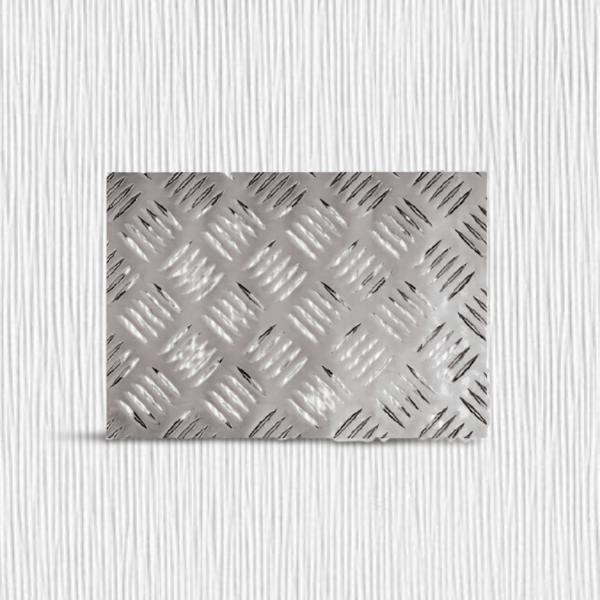

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Inconel 625 Plate

-

UNS N06625 Circle US $44 - $46 / Kg

-

ASTM B443 Inconel 625 2B Finish US $47 - $50 / Kg

-

DIN 2.4856 Clad Plate US $45 - $49 / Kg

-

ASTM BB443 Inconel 625 CR Sheet US $46 - $47 / Kg

-

ASME SB443 Inconel 625 Coil US $44 - $50 / Kg

Equivalent Grades Of Inconel 625 Plate

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN | OR |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NC22DNB4M | NA 21 | ХН75МБТЮ | NiCr22Mo9Nb | ЭИ602 |

Chemical Composition Of Inconel 625 Plate

| Ni | Fe | C | Mn | Si | Cr2 | Mo | Co | Al | Ti | Nb + Ta | P | S |

| 58.0 min | 5.0 max | 0.10 max | 0.50 max | 0.50 max | 20.0-23.0 | 8.0-10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15–4.15 | 0.015 max | 0.015 max |

Mechanical Properties Of Inconel 625 Plate

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Different Types Of Inconel 625 Plate

Our Manufacturing Process Of Inconel 625 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Plate

Our Material

Contact Us

Supplying World Wide