Inconel 600 Plate

Home » Inconel 600 Plate

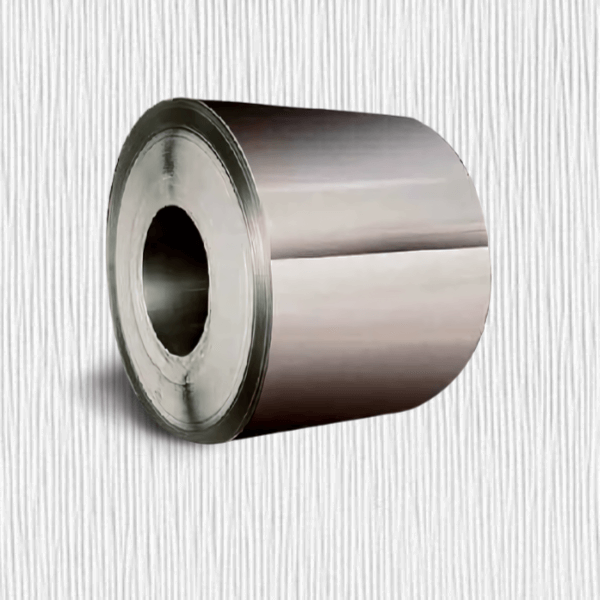

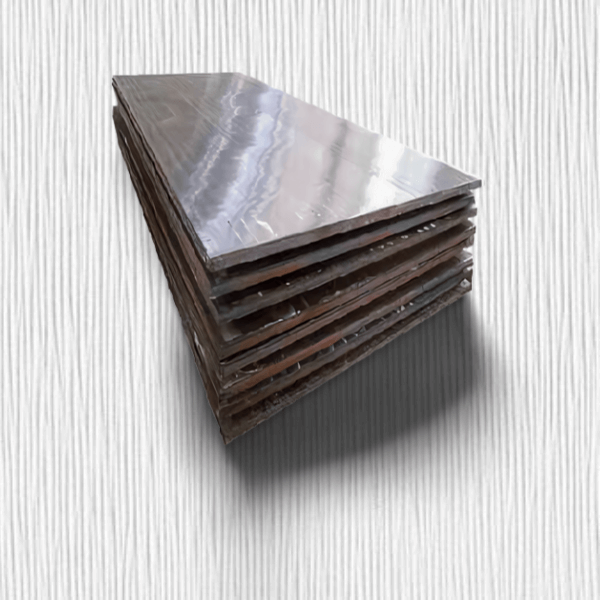

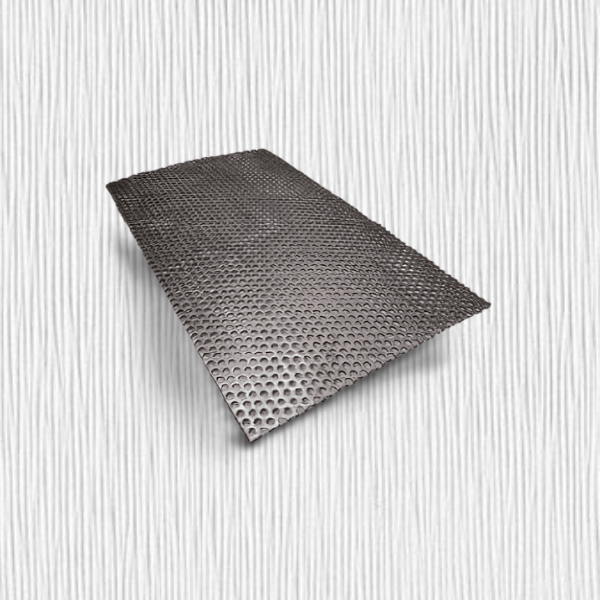

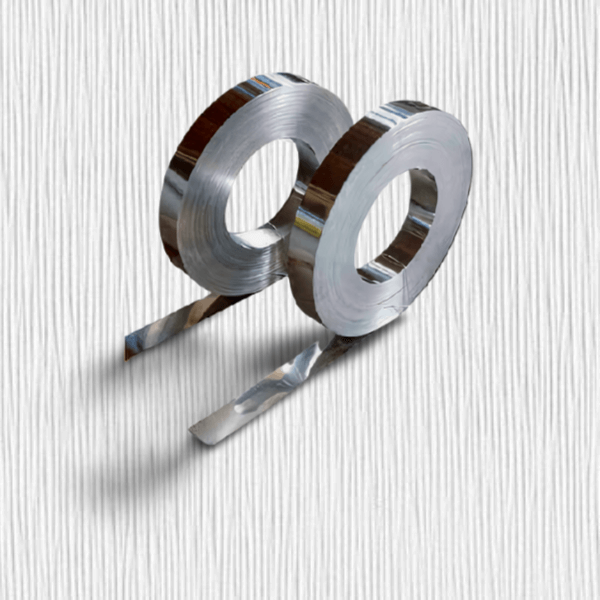

UNS N06600 Foil Sheet, DIN 2.4816 Shims, DIN 2.4816 Clad Plate, ASTM B168 Inconel 600 Sheets, UNS N06600 Circle, ASTM B168 Inconel 600 CR Sheet, ASTM B168 Inconel 600 Perforated Sheets, DIN 2.4816 Hot Rolled Sheet, ASTM B168 Inconel 600 2B Finish.

Inconel 600 is a nickel-chromium alloy that is known for its high-temperature strength and outstanding corrosion resistance. This superalloy plate has become an important material for applications that require durability in extreme environments.

The main reason UNS N06600 Foil Sheet stands up so well to heat and corrosion is its chemical composition. It contains a minimum of 72% nickel, with chromium making up 14-17% of the alloy. Minor amounts of iron, manganese, silicon, carbon and sulphur are also present. The high nickel content gives Inconel 600 its high-temperature strength. Meanwhile, chromium provides excellent resistance to corrosion and oxidation.

When an DIN 2.4816 Shims is produced, it goes through careful processing that ensures optimal microstructure and properties. The plate is first hot rolled before being annealed and descaled. This relieves stresses from rolling and gives the metal a uniform fine-grain structure. The plate can then be cold rolled to precise thicknesses as required. Extra steps like shot peening or polishing may also be used when a more refined surface finish is needed.

The outstanding properties of the Inconel 600 plate make it a frequent choice for demanding applications where heat and corrosion pose a threat to component integrity. Inconel 600 maintains its strength and resists expansion or rupture even when exposed to temperatures up to 1000°C in oxidizing environments. It is often used to fabricate retorts, muffles and other furnace components. The aerospace industry relies on Inconel 600 for exhaust manifolds, combustion cans and other parts close to hot turbine sections.

When corrosion resistance is the priority, the Inconel 600 is again a top option. The alloy stands up very well to various acids, alkalis and salts. Key applications taking advantage of this capability include heat exchangers, condensers and piping exposed to harsh industrial chemicals. The nuclear industry also values Inconel 600 for its resistance to radioactive environments. Reactor components like fuel element spacers and control rod drive mechanisms are commonly made from nickel-based plates.

Specification Of Inconel 600 Plate

| Specifications | ASTM B168 / ASME SB168 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

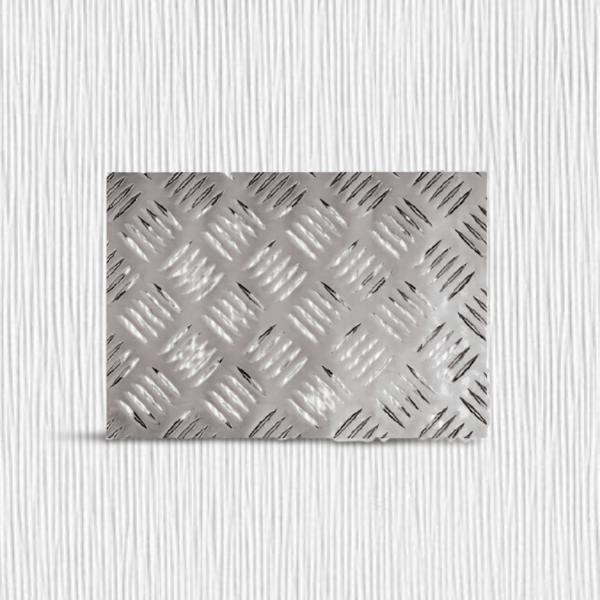

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Inconel 600 Plate

-

ASTM B168 Inconel 600 2B Finish US $44 - $50 / Kg

-

ASME SB168 Inconel 600 Coil US $46 - $47 / Kg

-

UNS N06600 Circle US $44 - $46 / Kg

-

DIN 2.4816 Clad Plate US $47 - $50 / Kg

-

ASTM B168 Inconel 600 CR Sheet US $45 - $49 / Kg

Equivalent Grades Of Inconel 600 Plate

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | NiCr15Fe | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 |

Chemical Composition Of Inconel 600 Plate

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015 max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Mechanical Properties Of Inconel 600 Plate

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | 655 MPa, 95000 psi | 310 MPa, 45000 psi | 45 % |

Different Types Of Inconel 600 Plate

Our Manufacturing Process Of Inconel 600 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Plate

Our Material

Contact Us

Supplying World Wide