Inconel 601 Fasteners

Home » Inconel 601 Fasteners

Werkstoff Nr 2.4851 Bolt, ASTM B166 Inconel 601 Nut, ASTM B166 Inconel 601 Nut, ASTM B166 Inconel 601 Fasteners, UNS N06601 Threaded Rod, ASME SB166 Inconel 601 Bolt, UNS N06601 Stud Bolt, ASME SB166 Inconel 601 Hex Nut, UNS N06601 Stud Bolt, Werkstoff Nr 2.4851 Threaded Rod.

Inconel 601 is a nickel-chromium alloy superb for fasteners. Its key properties make it ideal. First, high strength at extreme temperatures. It excels from cryogenic up to 2000°F and has outstanding corrosion resistance across many environments. They also have excellent fracture toughness for reliable joining.

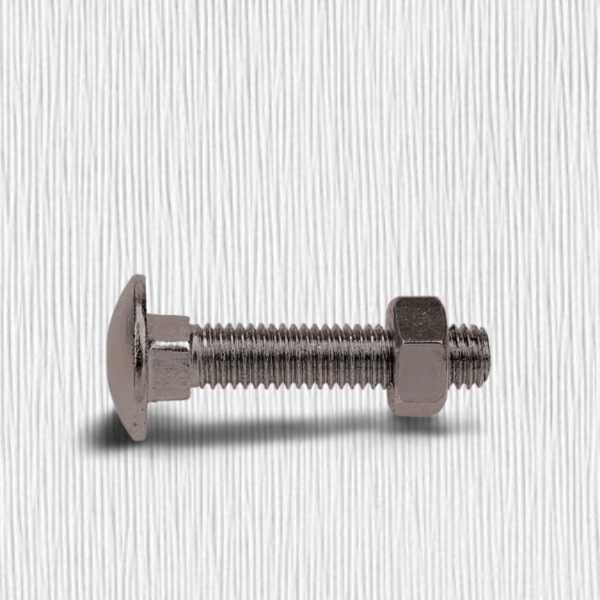

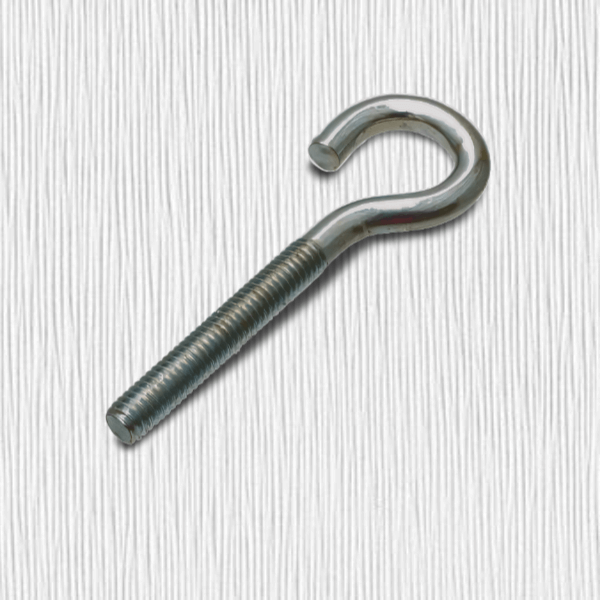

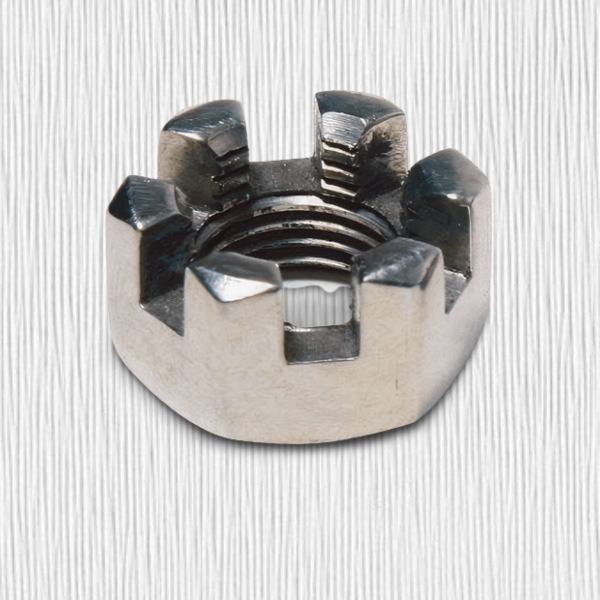

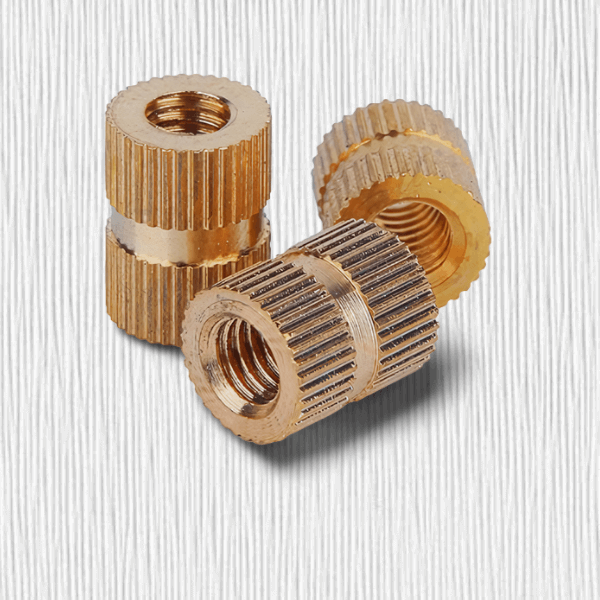

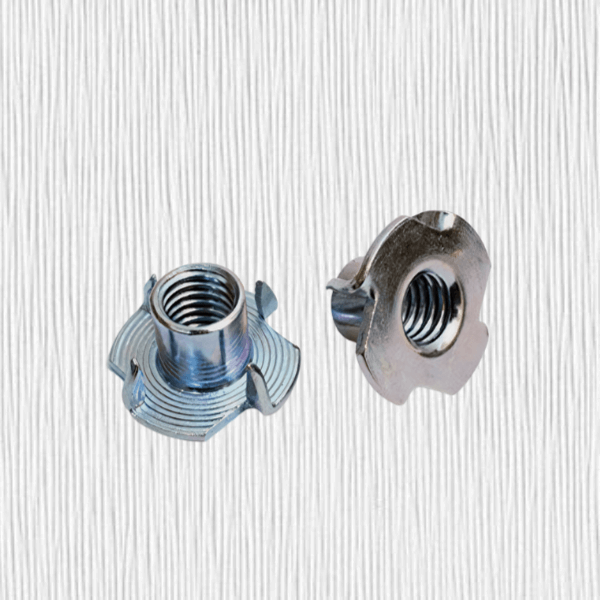

Fasteners are hardware used to join materials together securely and some common examples are bolts, screws, nuts, and rivets. They play vital roles in many industries.

There is 60% nickel, 23% chromium, and 14% iron in the metal. Minor elements like aluminium and manganese enhance properties further.

This unique composition results in remarkable capabilities. It forms a tenacious oxide layer preventing corrosion. The nickel matrix ensures strength persists at high temperatures. And its austenitic microstructure delivers superb toughness.

Anywhere uncompromising performance is paramount, these fasteners are good very well. Oil/gas, chemical processing, and power generation are major applications. The bolts, nuts, and studs secure critical equipment safely. They endure gruelling conditions of heat, pressure, and harsh fluids year after year.

In Aerospace. they are used to join sections on aircraft engines, rocket nozzles, and exhaust systems as lightweight strength and oxidation resistance are musts. During flight, temperatures can spike to over 1800°F while still needing immense load-bearing ability.

Other uses are in pollution control equipment, nuclear components, and even top-tier motorsports. Essentially any scenario where temperature extremes, corrosive media, and unrelenting stresses are factors.

Compared to common steel alloys, Alloy 601 fasteners costs substantially more. But the value lies in unmatched durability and reliability. Downtime, repairs, and risks of failure are vastly reduced over 25+ year lifespans.

Renine Metalloys LLP is a trustworthy Inconel 601 supplier & Manufacturer of all Inconel products. Contact us for more details on the Inconel 601 fasteners price.

Specification Of Inconel 601 Fasteners

| Standard | ASTM B166, ASME SB166 |

| Dimensions | ANSI B18.2.2, DIN 934,ISO 4032, BS1768, BS 1769 |

| Length | 3 mm to 200 mm |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Type | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Inconel 601 Fasteners

-

ASTM B166 Inconel 601 Washer US $44 - $50 / Kg

-

Werkstoff Nr 2.4851 Bolt US $46 - $47 / Kg

-

UNS N06601 Screw US $44 - $46 / Kg

-

ASME SB166 Inconel 601 Nut US $47 - $50 / Kg

-

ASTM B166 Inconel 601 Fasteners US $45 - $49 / Kg

Equivalent Grades Of Inconel 601 Fasteners

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 601 | N06601 | 2.4851 | NiCr23Fe | NiCr15Fe | NCF 601 | NA 49 | XH60BT | ЭИ868 |

Chemical Composition Of Inconel 601 Fasteners

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Mechanical Properties Of Inconel 601 Fasteners

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Different Types Of Inconel 601 Fasteners

Our Manufacturing Process Of Inconel 601 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Fasteners

Our Material

Contact Us

Supplying World Wide