Hastelloy X Flanges

Home » Hastelloy X Flanges

ANSI B16.5 Hastelloy X Spades-Rings-Spacer Flanges, ASTM B564 Hastelloy X Square Flange, ASTM B564 Hastelloy X Long-Weld-Neck Flange, ANSI B16.5 Hastelloy X Expander Flange, UNS N06002 Nuts-Bolts Flange, UNS N06002 Wnrf Flange, UNS N06002 Screwed Flange, DIN 2.4665 Weld-Neck Flange.

Renine Metalloys LLP is a distinguished manufacturer, stockist, and supplier of superior UNS N06002 Nuts-Bolts Flange. Our flanges are produced in compliance with national and international quality standards and come in various types, grades, sizes, and dimensions. To create these flanges, we employ a nickel, chromium, and molybdenum-based alloy, commonly called Hastelloy X. An added component, tungsten, enhances its resistance to corrosion and oxidation in extreme conditions.

Our exceptional DIN 2.4665 Weld-Neck Flange, characterized by superior flexibility, tensile strength, and durability, possess formidable corrosion resilience. They can effectively resist forms of degradation such as pitting, crevice corrosion, stress corrosion cracking, and abrasion, even under harsh conditions.

Their exceptional robustness and tensile strength render them capable of handling high pressure and temperature. With remarkable formability, weldability, and fabricability properties, these flanges have found wide-ranging applications in the petrochemical, pharmaceutical, paper and pulp industries and beyond.

Renine Metalloys boasts a state-of-the-art manufacturing unit with cutting-edge machinery and tooling to create DIN 2.4665 Flat Flange. A sizeable inventory ensures prompt delivery of orders within specified timelines. Our dedicated team utilizes contemporary techniques and equipment to manufacture premium flanges tailored to our esteemed clients’ requirements.

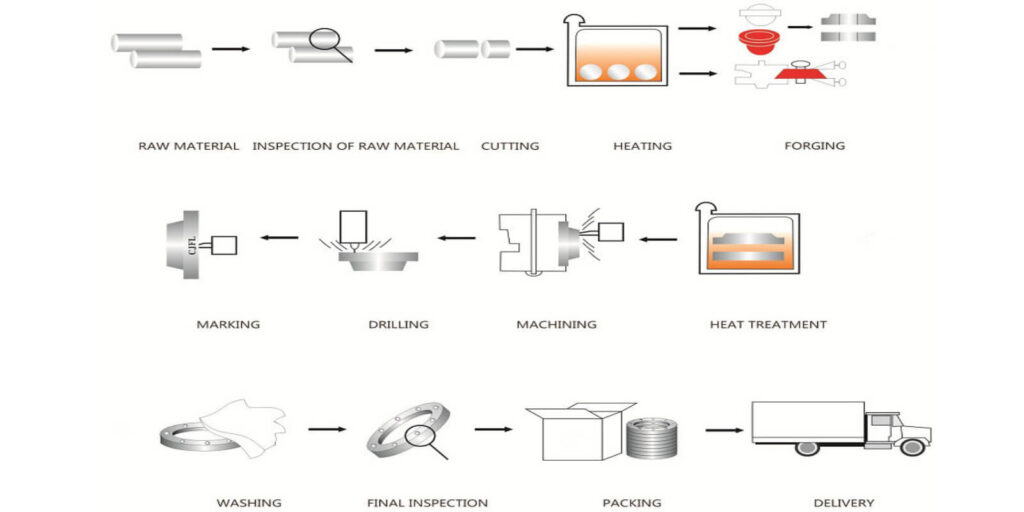

Each flange is created using the highest quality raw material, resulting in performance-oriented and low-maintenance products with impressive creep-rupture and stress-rupture properties. Our manufacturing process, overseen by seasoned experts, ensures that each production phase meets international quality standards.

We cater to the needs of a diverse clientele by offering Hastelloy X Flanges in both standard and customized specifications. Our proficient quality experts conduct rigorous tests, including various destructive and non-destructive inspections, to ensure the integrity and performance of each flange. Our policy is to only dispatch defect-free and dimensionally accurate Hastelloy X Flanges for packing. We use suitable packaging materials to prevent damage during transit and guarantee on-time delivery to our global patrons.

Specification Of Hastelloy X Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Hastelloy X Flanges

-

UNS N06002 Threaded Flange US $44 - $50 / Kg

-

DIN 2.4665 Weld-Neck Flange US $46 - $47 / Kg

-

ASTM B564 Hastelloy X Weld-Neck Flange-A-B US $44 - $46 / Kg

-

ANSI B16.5 Hastelloy X Weldo-Nipo Flange US $47 - $50 / Kg

-

UNS N06002 Wnrf Flange US $45 - $49 / Kg

Equivalent Grades Of Hastelloy X Flanges

| STANDARD | UNS | WNR. |

| Hastelloy X | N06002 | 2.4665 |

Chemical Composition Of Hastelloy X Flanges

| Grade | C | Mn | Si | Cu | Co | Ni | Cr | Fe | Mo | Ti |

| Hastelloy X | 0.05 – 0.15 | 1.0 max | 1.0 max | 0.50 max | 0.5 – 2.5 | Remainder | 20.5-23.0 | 17.0-20.0 | 8.0-10.0 | 0.15 max |

Mechanical Properties Of Hastelloy X Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy X | 8.22 g/cm³ | 1355°C | 655 MPa | 240 MPa | 35 % |

Different Types Of Hastelloy X Flanges

Our Manufacturing Process Of Hastelloy X Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Hastelloy Flanges

Our Material

Contact Us

Supplying World Wide