Hastelloy G3 Flanges

Home » Hastelloy G3 Flanges

Hastelloy G3 Threaded Flange, UNS N06985 Swrf Flange, Hastelloy G3 Screwed Flange, Hastelloy G3 Orifice Flange, Hastelloy Alloy G3 Weld-Neck Flange, Hastelloy Alloy G3 Flat Flange, DIN 2.4619 Weld-Neck Flange-A-B, UNS N06985 Forging Facing Flange, Hastelloy Alloy G3 Lap-Joint Flange.

As a distinguished manufacturer, supplier, and exporter, Renine Metalloys LLP takes pride in crafting superior JIS NW 0276 Loose Flange. These flanges, available in varied shapes, sizes, dimensions, and specifications, are offered in standard and bespoke versions. Distinguished by its resistance to severe acids and alkalis and virtually immune to chlorides, Hastelloy represents a versatile corrosion-resistant alloy comprised of nickel, molybdenum, and chromium.

Customization options are generously offered for our Hastelloy Flanges to meet the unique needs of every client. Delivering excellent resistance against crevice corrosion, stress corrosion, and pitting, Hastelloy G3 Screwed Flange are renowned for their potent tensile strength, resilience, flexibility, and extended service life.

Their fabrication and machinability are effortless, leading to a strong preference from customers for their commendable workability and superior finish. In addition, their robust construction is well recognized and appreciated.

At Renine Metalloys LLP, we craft top-tier Hastelloy Flanges that resonate with the latest industrial demands. Our flanges, which are reliable for various industries such as the fertilizer sector, construction, petrochemical plants, refineries, paper mills, cement plants, pharmaceuticals, and bioprocessing, adhere to international quality standards. Each Hastelloy Long Weld Neck Flange is manufactured in diverse sizes and dimensions, adhering to strict accuracy. The integral use of high-quality raw materials further enhances the performance of these flanges.

Our production process for UNS N06985 Swrf Flange incorporates innovative technology, making the most of first-rate machinery, premium raw materials, and a skilled workforce. This approach allows us to meet each customer’s specific requirement with products of various designations, specifications, and dimensions. Each Hastelloy Flange undergoes many tests our expert quality analysts conduct to uphold a robust standard throughout the production process. We rely on state-of-the-art packaging methods to prevent damage during transport. Value delivery and excellent client relationships are at the core of Renine Metalloys LLP philosophy. We assure prompt deliveries at our client’s convenience and offer our premium products at reasonable rates.

Specification Of Hastelloy G3 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Hastelloy G3 Flanges

-

UNS N06985 RTJ Flange US $44 - $50 / Kg

-

Hastelloy G3 Screwed Flange US $46 - $47 / Kg

-

Hastelloy Alloy G3 Slip-On Flange US $44 - $46 / Kg

-

DIN 2.4619 Socket-Weld Flange US $47 - $50 / Kg

-

UNS N06985 Spades-Rings-Spacer Flanges US $45 - $49 / Kg

Equivalent Grades Of Hastelloy G3 Flanges

| STANDARD | UNS | WNR. |

| Hastelloy G3 | N06985 | 2.4619 |

Chemical Composition Of Hastelloy G3 Flanges

| Ni | Cr | Fe | Mo | Cu | Nb+Ta | C | W | Si | Mn | P | S | Co |

| Balance | 21.0-23.5 | 18.0-21.0 | 6.0-8.0 | 1.5-2.5 | ≤0.50 | ≤0.015 | ≤1.5 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ≤5.0 |

Mechanical Properties Of Hastelloy G3 Flanges

| Tensile Strength, min. | Yield Strength, min. | Elongation, min. | Hardness, min. | ||

| Mpa | ksi | Mpa | ksi | % | HRB |

| 690 | 100 | 320 | 47 | 50 | 79 |

Different Types Of Hastelloy G3 Flanges

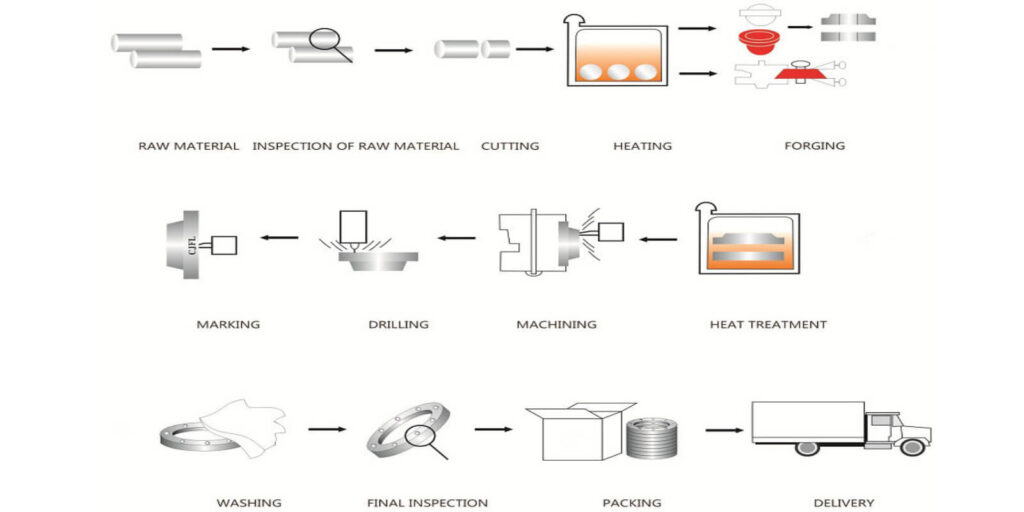

Our Manufacturing Process Of Hastelloy G3 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Hastelloy Flanges

Our Material

Contact Us

Supplying World Wide