Super Duplex 32750 Forged Fitting

Home » Super Duplex 32750 Forged Fitting

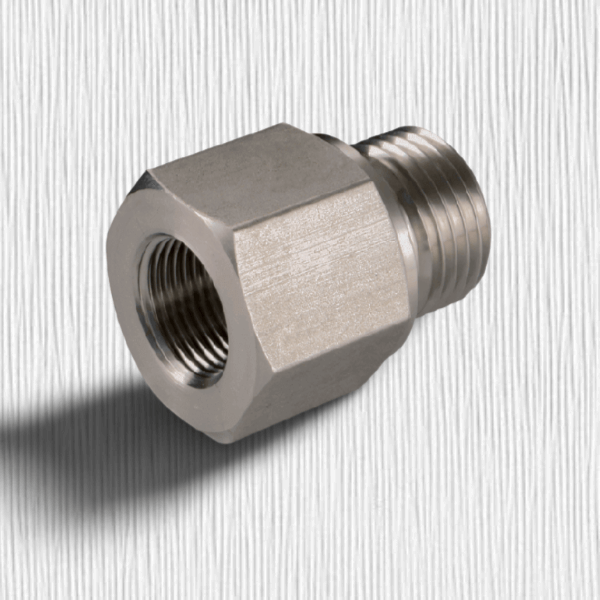

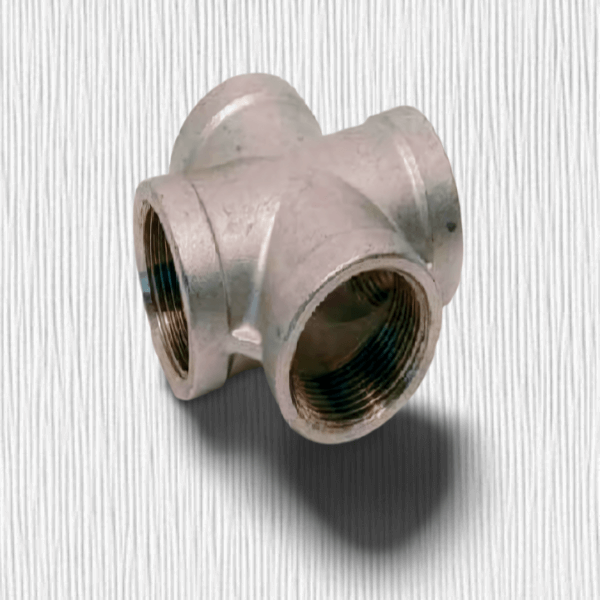

ASTM A182 Super Duplex 32750 Forged Threaded Lateral Outlet, ASTM A182 Super Duplex 32750 Forged Reducing Cross Forged Fitting, ASME SA182 Super Duplex 32750 Forged Hex Plug, ASTM A182 Super Duplex 32750 Forged Threaded Plug, UNS S32750 Threaded Screwed Street Elbow Forged Fitting, DIN 1.4410 Threaded Unequal Tee.

Super Duplex 32750 Forged Fittings play a role, as components made from the high performance Super Duplex 32750 stainless steel grade. These fittings undergo forging techniques to boost their durability, strength and resistance to corrosion making them well suited for demanding settings.

An outstanding feature of these fittings is their resistance to corrosion. The Super Duplex 32750 stainless steel grade excels in withstanding environments including those with chloride ions, sulfuric acid and seawater. This corrosion resistance makes them highly suitable for industries like oil and gas operations, chemical processing plants and marine installations.

Moreover the Super Duplex 32750 Forged Fittings demonstrate strength and toughness due to the dual phase microstructure characteristic of super duplex stainless steels. This heightened strength enables these fittings to perform in pressure and high temperature applications where robust performance is crucial.

Further more apart from their corrosion resistance and mechanical robustness these forged fittings exhibit fatigue resistance and resilience against stress corrosion cracking. These attributes ensure that the fittings can endure loads and challenging conditions while maintaining their structural integrity intact over prolonged periods of use.

The process of creating Super Duplex 32750 Forged Fittings involves shaping the components to have a defined structure, consistent grain flow and improved qualities, like resistance to impacts and ease of welding. This results in fittings that’re sturdy and long lasting able to endure working conditions.

Super Duplex 32750 Forged Fittings are an option for industries that need resistance to corrosion, mechanical durability and longevity. Their exceptional performance features and dependability make them a favored selection, for systems prioritizing safety and efficiency.

Specification Of Super Duplex 32750 Forged Fitting

| Specifications | ASTM A182 & ASME SA182 |

| Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Dimensions | ASME 16.11, MSS SP-79,83,95,97,BS 3799 |

| Size | 1/2"NB TO 4"NB IN |

| Class / Pressure | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | SOCKET WELD (S/W) & SCREWED (SCRD), Threaded – NPT, BSP, BSPT |

Price List Of Super Duplex 32750 Forged Fitting

-

ASTM A182 Super Duplex 32750 Forged Weld Tee US $12 - $15 / Kg

-

ASME SA182 Super Duplex 32750 Forged Hex Plug US $13 - $15 / Kg

-

UNS S32750 Reducing Insert Socket Forged Fittings US $13 - $14 / Kg

-

DIN 1.4410 Threaded Equal Tee Forged Fitting US $14 - $15 / Kg

-

ASTM A182 Super Duplex 32750 Forged Threaded Lateral Outlet US $12 - $15 / Kg

Equivalent Grades Of Super Duplex 32750 Forged Fitting

| STANDARD | UNS | WERKSTOFF NR. |

| Super Duplex 2507 | S32750 | 1.4410 |

Chemical Composition Of Super Duplex 32750 Forged Fitting

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

Mechanical Properties Of Super Duplex 32750 Forged Fitting

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000, MPa – 800 | Psi – 80000, MPa – 550 | 15 % |

Different Types Of Super Duplex 32750 Forged Fitting

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Super Duplex Forged Fitting

Our Material

Contact Us

Supplying World Wide