Nickel 200 Fasteners

Home » Nickel 200 Fasteners

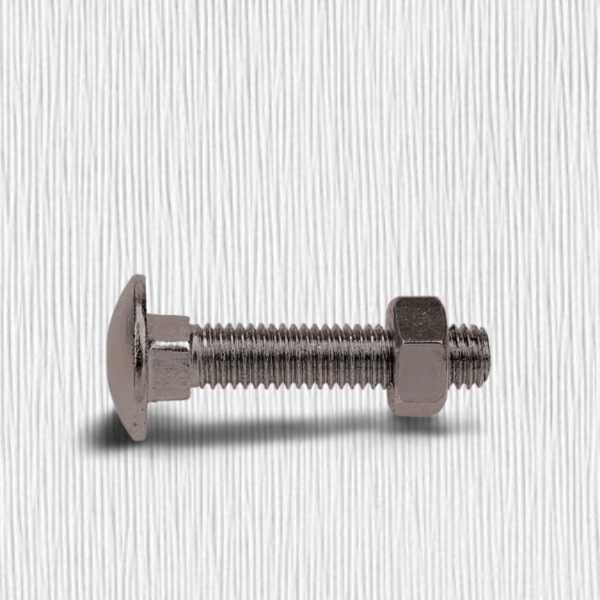

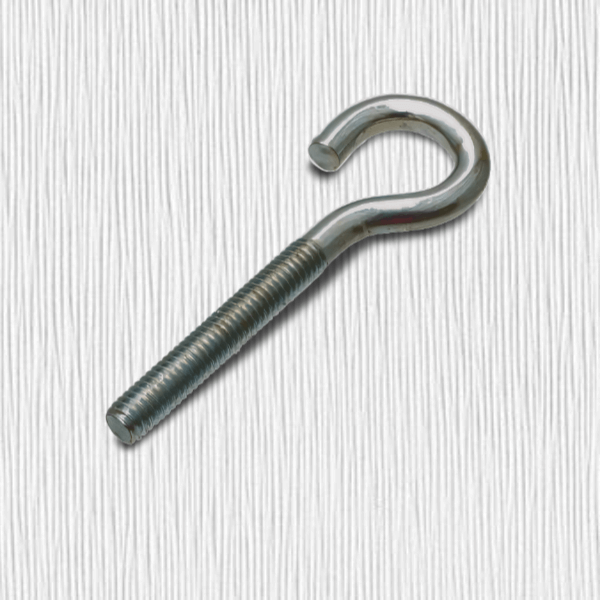

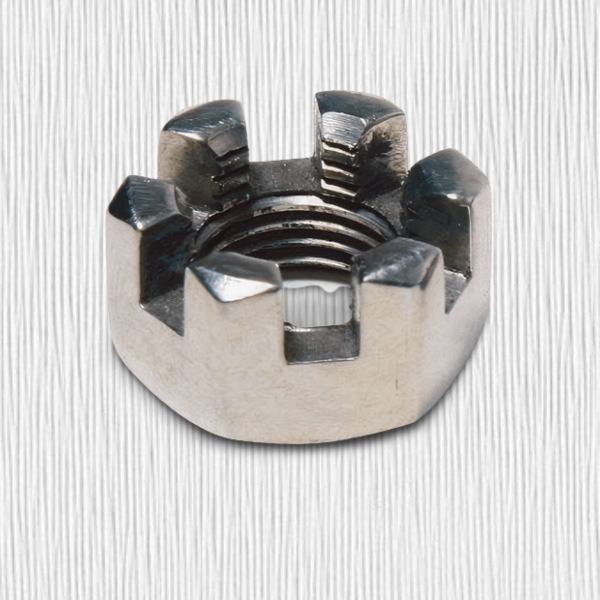

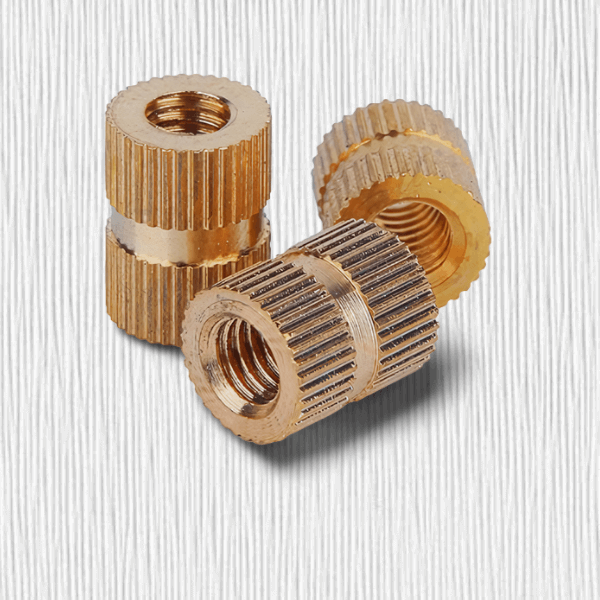

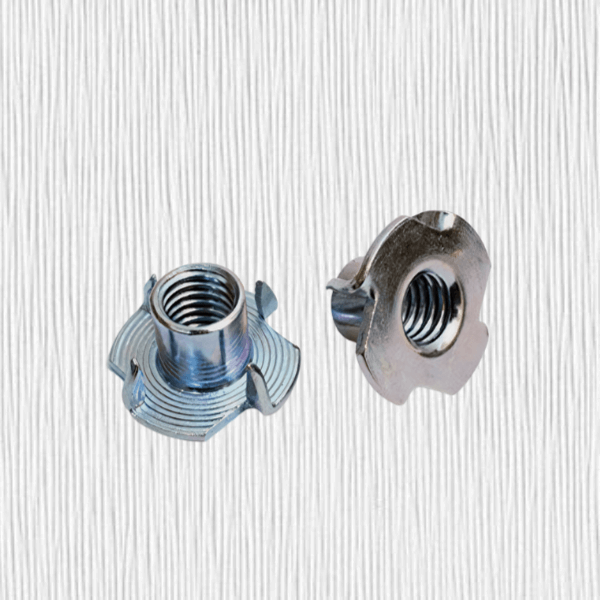

Werkstoff Nr 2.4066 Threaded Rod, Werkstoff Nr 2.4066 Hex Nut, JIS NW 2200 Nut, ASTM B160 Nickel 200 Fasteners, ASTM B160 Nickel 200 Bolt, UNS N02200 Stud Bolt.

Nickel 200 is a solid metal alloy containing nickel. It has great corrosion resistance properties and these fasteners are used in many harsh environments.

The alloy consists of 99.6% nickel with the remaining elements in small amounts that make it powerful and very hard which allows it to survive under the harshest temperatures.

Nickel 200 fasteners is highly resistant to various media that are corroding and is widely used in heating elements. This includes caustic solutions, marine atmospheres, and more. Its corrosion resistance comes from the nickel content.

These UNS N02200 Stud Bolt fasteners are often used in chemical processing equipment. They are also found in oil/gas and power industries and also in any application needing corrosion resistance uses them. Heat exchangers, condensers, and piping systems make use of these fasteners and also power plants use them in areas like superheaters.

ASTM B160 Nickel 200 Bolt’s remarkable anti-corrosion properties are worth praising. With its high nickel content, these fasteners perform strong and work well even in rough industrial conditions.

Nickel 200 has great machining characteristics as well. It machines easily and holds tight tolerances and also these alloys are 100% non-magnetic and non-sparking. It’s suited for hazardous areas with flammable materials and is used in many aircraft and marine applications.

The high nickel content gives it resistance to oxidation which can handle temperatures up to 1800°F and makes it great for high-heat applications. Nickel 200 is easily welded and fabricated as well. It has good ductility and formability properties. This allows complex shapes to be formed. These Werkstoff Nr 2.4066 Nut have high strength and toughness. The yield strength is around 35 ksi and the creep and stress-rupture properties are also excellent.

Renine Metalloys LLP is a trustworthy Nickel 200 Supplier & Manufacturer of all Nickel alloy products. Contact us for more details on the Nickel 200 Price List.

Specification Of Nickel 200 Fasteners

| Specification | ASTM B160 / ASME SB160 |

| Dimensional specification | ASTM, ASME and API |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

| Form | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Nickel 200 Fasteners

-

ASTM B160 Nickel 200 Bolt US $44 - $50 / Kg

-

Werkstoff Nr 2.4066 Nut US $46 - $47 / Kg

-

UNS N02200 Fasteners US $44 - $46 / Kg

-

JIS NW 2200 Screw US $47 - $50 / Kg

-

Werkstoff Nr 2.4066 Washer US $45 - $49 / Kg

Equivalent Grades Of Nickel 200 Fasteners

| STANDARD | UNS | WNR. | JIS | EN |

| Nickel 200 | N02200 | 2.4066 | NW 2200 | Ni 99.2 |

Chemical Composition Of Nickel 200 Fasteners

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Of Nickel 200 Fasteners

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Different Types Of Nickel 200 Fasteners

Our Manufacturing Process Of Nickel 200 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Nickel Fasteners

Our Material

Contact Us

Supplying World Wide