Inconel 602CA Forged Fitting

Home » Inconel 602CA Forged Fitting

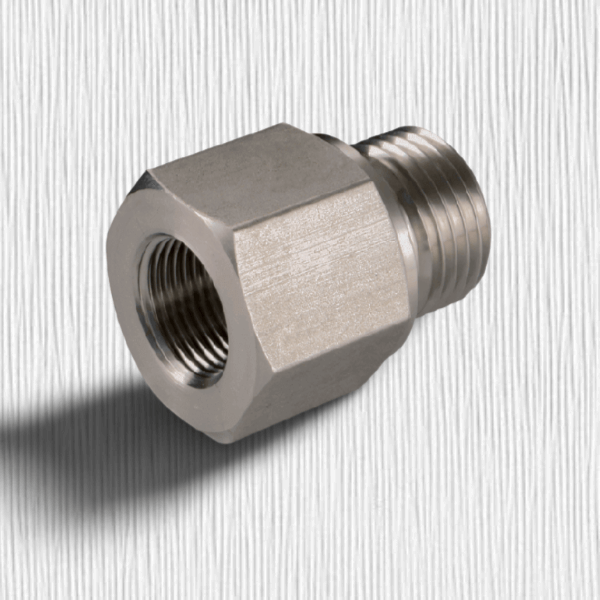

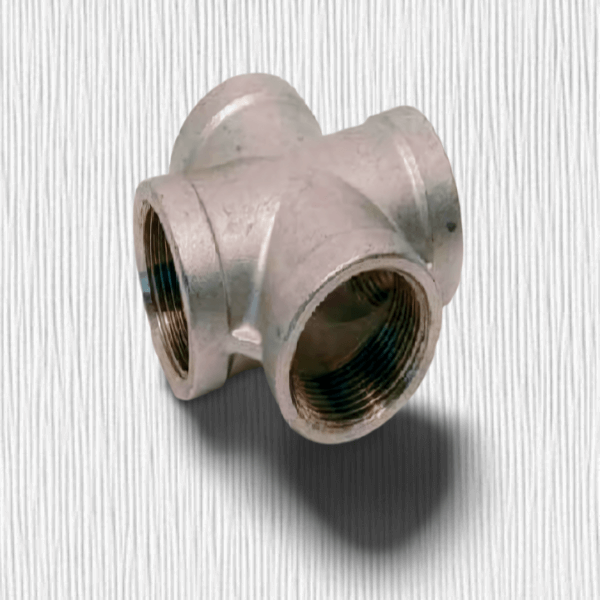

ASTM B168 Inconel 602CA Forged Threaded Plug, ASTM B168 Inconel 602CA Forged Threaded Pipe Nipples, UNS N06025 Forged Adapter Fitting, DIN 2.4633 Forged Sockolet Fitting, DIN 2.4633 Forged Full Coupling, ASME SB168 Inconel 602CA Forged Threaded Reducing Tee, DIN 2.4633 Forged Threaded Lateral Tee.

Inconel 602CA is an alloy that is highly regarded for its ability to resist oxidation and carburization at high temperatures. Transforming it into forged fittings brings out its role, in applications that require top notch performance in conditions. The reliability and durability of UNS N06025 Forged Tee forged fittings shine in industries facing temperatures and corrosive surroundings.Forged fittings made from Inconel 602CA excel in environments enduring temperatures high as 2250°F (1232°C) while maintaining their mechanical qualities. This exceptional heat resilience makes them ideal for tasks demanding performance at heat levels. With resistance to oxidation and carburization Inconel 602CA stands out as an option for applications exposed to corrosive gases and harsh combustion settings. Its sturdy nature ensures longevity and dependability in challenging situations.

The robust creep strength of Inconel 602CA forged fittings enables them to uphold their integrity when subjected to heavy loads and elevated temperatures, which is crucial for scenarios requiring extended exposure to high heat levels. Beyond its heat endurance DIN 2.4633 Threaded Pipe Nipples also boasts superb corrosion resistance making it well suited for use, in chemical processing plants, petrochemical industries and power generation facilities where dealing with conditions is a significant consideration. UNS N06025 Forged Adapter Fitting find use in refineries, chemical plants and offshore drilling rigs where withstanding temperatures and corrosive substances is crucial.

These fittings are components, in power plants in gas turbines combustion chambers and exhaust systems ensuring dependable performance, in challenging thermal conditions.Inconel 602CA forged fittings are utilized in heat treatment machinery like annealing and carburizing furnaces for their capacity to endure temperatures and harsh environments.

Specification Of Inconel 602CA Forged Fitting

| Specifications | ASTM B168 / ASME SB168 |

| Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Dimensions | ASME 16.11, MSS SP-79,83,95,97,BS 3799 |

| Size | 1/2"NB TO 4"NB IN |

| Class / Pressure | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | SOCKET WELD (S/W) & SCREWED (SCRD), Threaded – NPT, BSP, BSPT |

Price List Of Inconel 602CA Forged Fitting

-

ASTM B168 Inconel 602CA Forged Cap US $44 - $50 / Kg

-

ASME SB168 Inconel 602CA Forged Cross US $46 - $47 / Kg

-

UNS N06025 Forged Adapter Fitting US $44 - $46 / Kg

-

DIN 2.4633 Forged Full Coupling US $47 - $50 / Kg

-

ASTM B168 Inconel 602CA Forged Tee US $45 - $49 / Kg

Equivalent Grades Of Inconel 602CA Forged Fitting

| STANDARD | UNS | WNR. |

| Inconel 602CA | N06025 | 2.4633 |

Chemical Composition Of Inconel 602CA Forged Fitting

| Alloy | % | Cr | Cu | Ni | P | S | Fe | C | Al | Ti | Y | Zr | Si | Mn |

602CA | Min. | 24.0 | - | balance | - | - | 8.0 | 0.15 | 1.8 | 0.1 | 0.05 | 0.01 | - | - |

Max. | 26.0 | 0.1 | 0.02 | 0.01 | 11.0 | 0.25 | 2.4 | 0.2 | 0.12 | 0.1 | 0.5 | 0.15 |

Mechanical Properties Of Inconel 602CA Forged Fitting

| Temperature, ° F | 68 | 1000 | 1500 | 1600 | 1800 | 2000 | 2200 |

| Ultimate Tensile Strength, ksi | 105 | 93.4 | 41.2 | 32.8 | 17.1 | 13 | 5.8 |

| 0.2%Yield Strength, ksi | 50.5 | 38.3 | 34.8 | 28.7 | 15.2 | 11.6 | 5.0 |

| Elongation, % | 38 | 43 | 78 | 82 | 78 | 85 | 96 |

Different Types Of Inconel 602CA Forged Fitting

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Forged Fitting

Our Material

Contact Us

Supplying World Wide