Hastelloy C2000 Plate

Home » Hastelloy C2000 Plate

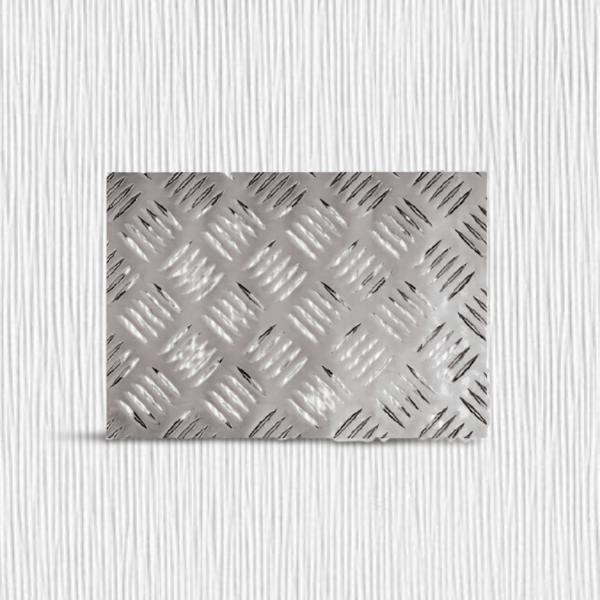

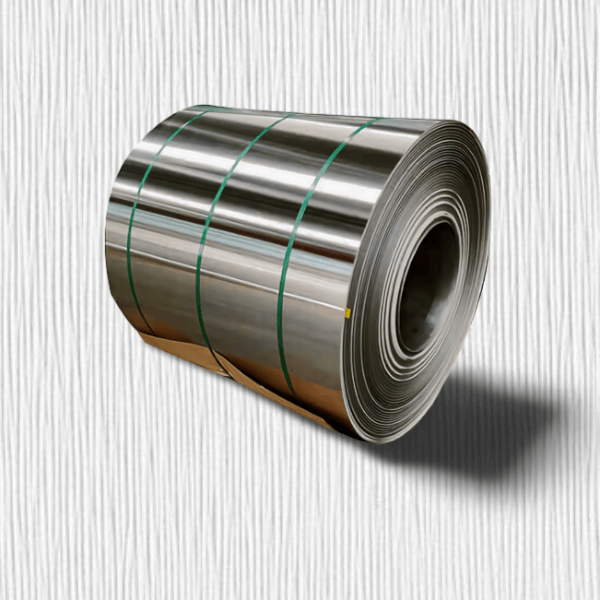

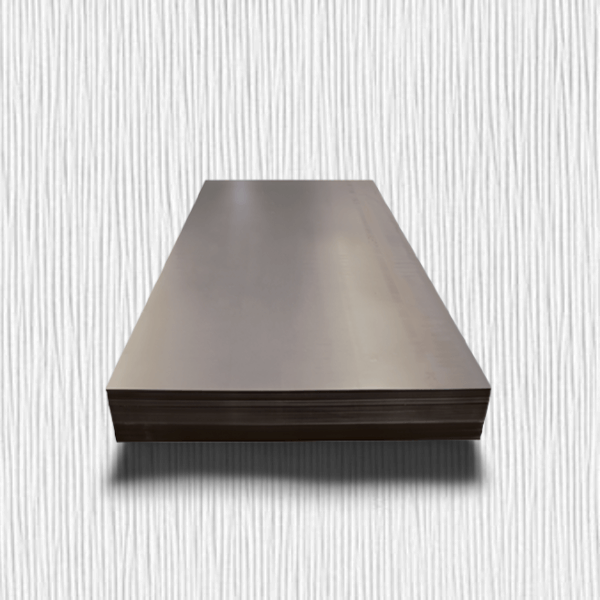

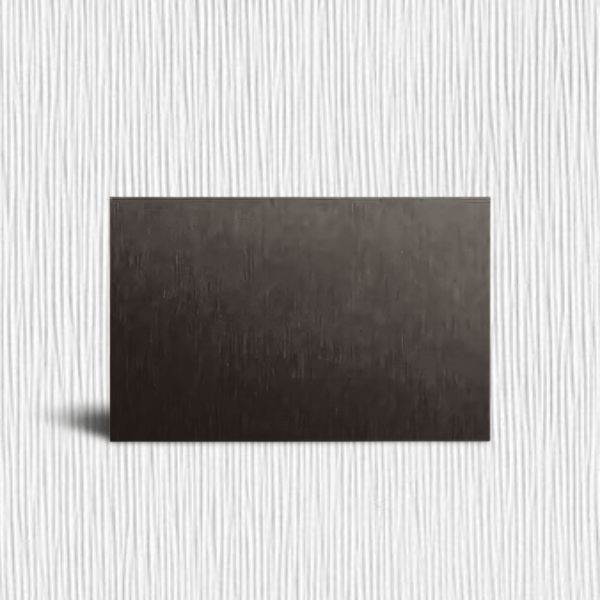

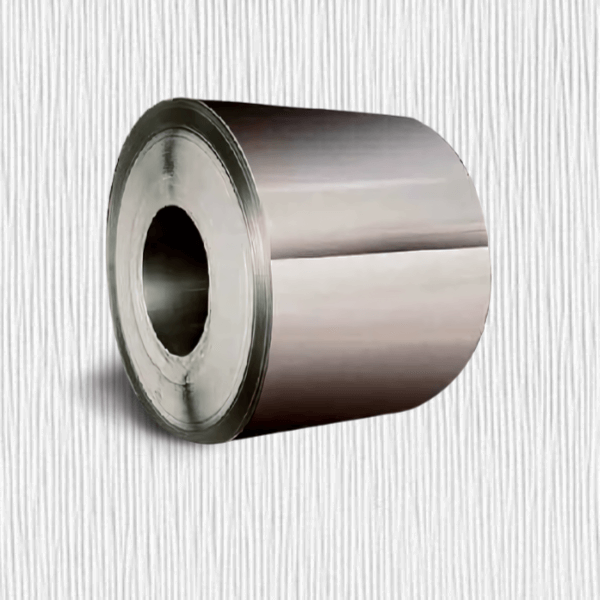

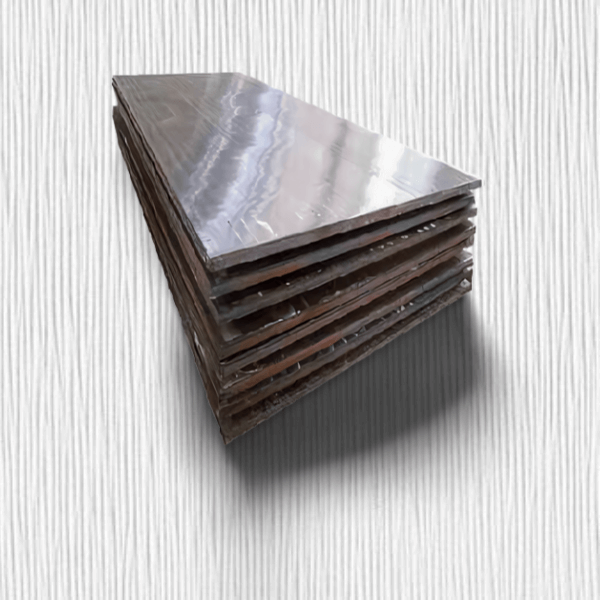

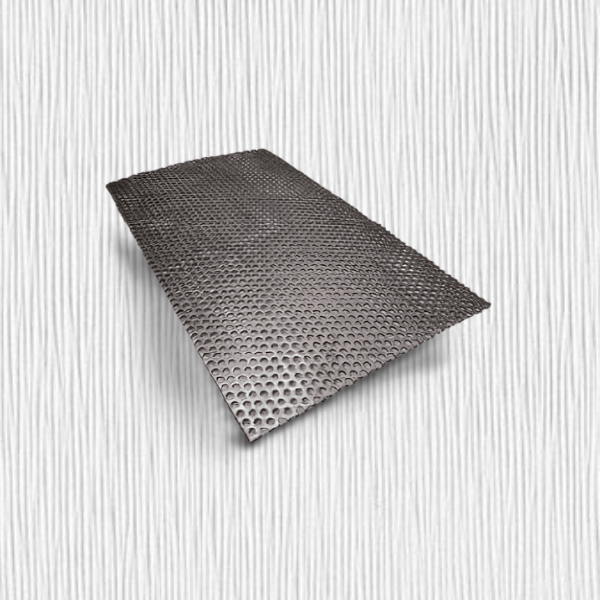

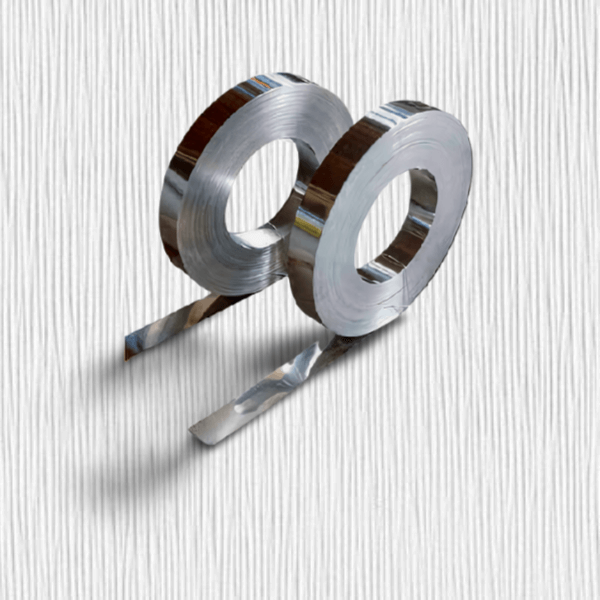

ASME SB574 Hastelloy C2000 Rolls, UNS N06200 Plain Sheet, UNS N06200 Ring, ASTM B574 Hastelloy C2000 Perforated Sheets, ASME SB574 Hastelloy C2000 Plate, ASTM B574 Hastelloy C2000 CR Sheet, ASTM B574 Hastelloy C2000 2B Finish, ASME SB574 Hastelloy C2000 Flats, DIN 2.4675 Clad Plate.

Hastelloy C2000 is a nickel-chromium-molybdenum-tungsten alloy that has great resistance to corrosion. It is often used to make plates for applications that require high strength and the ability to withstand extreme environments.

The alloy composition gives Hastelloy C2000 unmatched protection against corrosion, even when exposed to hydrochloric, sulfuric, and acetic acids. This resistance also applies under oxidizing conditions at high temperatures. As a result, UNS N06200 Plain Sheet last longer than other materials.In addition to corrosion resistance, C2000 plates also have great tensile strength. They are often stronger than plates made of stainless steel grades. At high temperatures, C2000 retains good ductility and plasticity while remaining strong.

It is exceptionally durable for applications with temperature fluctuations or thermal shocks.Despite its high strength, C2000 alloy is relatively easy to cut, form, machine and weld compared to other nickel alloys. Standard shop methods can be used. This gives engineers and designers flexibility when working with the DIN 2.4675 Clad Plate.. The material can meet tighter tolerances.

Hastelloy C2000 has excellent high-temperature strength up to 1,600°F (870°C), much higher than stainless steels. It maintains good ductility and toughness rather than becoming brittle. This is vital where fluctuating service temperatures are expected. It also handles cryogenic temperatures.

When directly exposed, C2000 plates are compatible with many other metal alloys and materials used in high-temperature environments. It won’t negatively impact other metals it contacts. This versatility makes system design easier.

UNS N06200 Ring provides unmatched corrosion resistance along with strength and durability. It is perfect for applications that demand reliability in even the most extreme conditions that would defeat other alloys. With care in fabrication, it can serve dependably for many years in harsh chemical, thermal, and mechanical environments. C2000’s capabilities make it a valuable material across industries requiring exceptional performance.

Specification Of Hastelloy C2000 Plate

| Specification | ASTM B575 / ASME SB575 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Hastelloy C2000 Plate

-

ASTM B574 Hastelloy C2000 2B Finish US $75 - $80 / Kg

-

ASME SB574 Hastelloy C2000 Coil US $76 - $79 / Kg

-

UNS N06200 Circle US $77 - $80 / Kg

-

DIN 2.4675 Clad Plate US $78 - $79 / Kg

-

ASTM B574 Hastelloy C2000 CR Sheet US $79 - $80 / Kg

Equivalent Grades Of Hastelloy C2000 Plate

| STANDARD | UNS | WNR. |

| Hastelloy C2000 | N06200 | 2.4675 |

Chemical Composition Of Hastelloy C2000 Plate

| Grade | Ni | Mo | Cr | Fe | W | Co | Mn | C | V | P | Si |

| Hastelloy C2000 | Remainder | 15.0-17.0 | 14.5-16.5 | 4.0-7.0 | 3.0-4.5 | 2.5 max | 1.0 max | .01 max | .35 max | .04 max | .08 max |

Mechanical Properties Of Hastelloy C2000 Plate

| Grade | Tensile Strength | Yield Strength | Elongation at break |

| Hastelloy C2000 | 690 MPa | 310 MPa | 45% |

Different Types Of Hastelloy C2000 Plate

Our Manufacturing Process Of Hastelloy C2000 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Hastelloy Plate

Our Material

Contact Us

Supplying World Wide