Alloy 28 Flanges

Home » Alloy 28 Flanges

DIN 1.4563 Weldo-Nipo Flange, DIN 1.4563 Spectacle-Blind Flange, DIN 1.4563 Lap-Joint Flange, UNS N08028 Nuts-Bolts Flange, ASTM B463 Alloy 28 Weld-Neck Flange-A-B, DIN 1.4563 Forged Flange, ASTM B463 Alloy 28 Blind Flange, ASTM B463 Alloy 28 Sorf Flange, ASTM B463 Alloy 28 Ring-Type-Joint Flange.

Renine Metalloys is widely recognized internationally as a leading manufacturer and supplier of Alloy 28 Flanges. Conforming strictly to national and international quality standards, our expert team meticulously designs these flanges. Alloy 28 is a distinguished nickel-iron-chromium alloy. Further refined by niobium stabilization and enhanced with copper and molybdenum, this alloy exhibits outstanding resistance to the corrosive effects of nitric acid, phosphoric, sulfuric, and chloride environments. The flanges demonstrate exceptional mechanical strength, whether subjected to high or ambient temperatures. Their manufacturing involves a variety of this alloy, including slip-on, blind, socket-weld, long weld neck, RTJ, and weld neck types, among others.

Our DIN 1.4563 Forged Flange display remarkable resistance to pitting corrosion, crevice corrosion, and rust, particularly in seawater contexts. They assure excellent tensile strength and elongation capacity in both acidic and seawater environments, and they exhibit exemplary toughness and resistivity in harsh climates. Combined with their premium chemical composition and mechanical properties, these attributes effectively enable the flanges to sustain high pressures and temperatures.

Offering a comprehensive UNS N08028 Reducing Flange, Renine Metalloys accommodates diverse customer requirements. Our range includes various sizes, specifications, standards, dimensions, and custom-made specifications. We guarantee superior quality flanges notable for their impressive durability, weldability, and fabricability, all produced by our seasoned manufacturing team. Sourcing from reliable vendors, the high-grade raw materials used in production undergo rigorous pre-use testing, ensuring the resultant flanges provide a long service life with minimal maintenance.

Our adept workforce, armed with cutting-edge techniques, state-of-the-art machinery, and sophisticated fabrication methods, expertly crafts our robust Alloy 28 Flanges. Every manufacturing phase is meticulously overseen under our experts’ continuous supervision and guidance. Furthermore, to cater to emergent needs, we maintain ample stocks of the Alloy 28 Flanges.

At Renine Metalloys, our commitment to quality control is exemplified by a dedicated team of quality experts. This team scrutinizes the Alloy 28 Flanges at every manufacturing stage until their final delivery. To validate the flanges’ durability and ductility, a series of destructive and non-destructive tests are conducted, and upon request, third-party inspections are arranged.

We dedicate ourselves to fulfilling all client requirements, guaranteeing our flanges’ timely and safe delivery. Our commitment to damage-free delivery is upheld via standard packaging methods while we ensure prompt delivery using the fastest transportation modes.

Specification Of Alloy 28 Flanges

| Specifications | ASTM B463 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Alloy 28 Flanges

-

UNS N08028 Nuts-Bolts Flange US $20 - $25 / Kg

-

ASTM B463 Alloy 28 Flat Flange US $23 - $24 / Kg

-

DIN 1.4563 Forged Flange US $22 - $23 / Kg

-

UNS N08028 Forging Facing Flange US $24 - $25 / Kg

-

ASTM B463 Alloy 28 Groove-Tongue Flange US $21 - $22 / Kg

Equivalent Grades Of Alloy 28 Flanges

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy 28 | N08028 | 1.4563 |

Chemical Composition Of Alloy 28 Flanges

| Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al |

| 30-32 | 22 min | 26-28 | 3-4 | 0.60-1.40 | - | 0.02 max | 2 max | 0.03 max | 0.70 max | - |

Different Types Of Alloy 28 Flanges

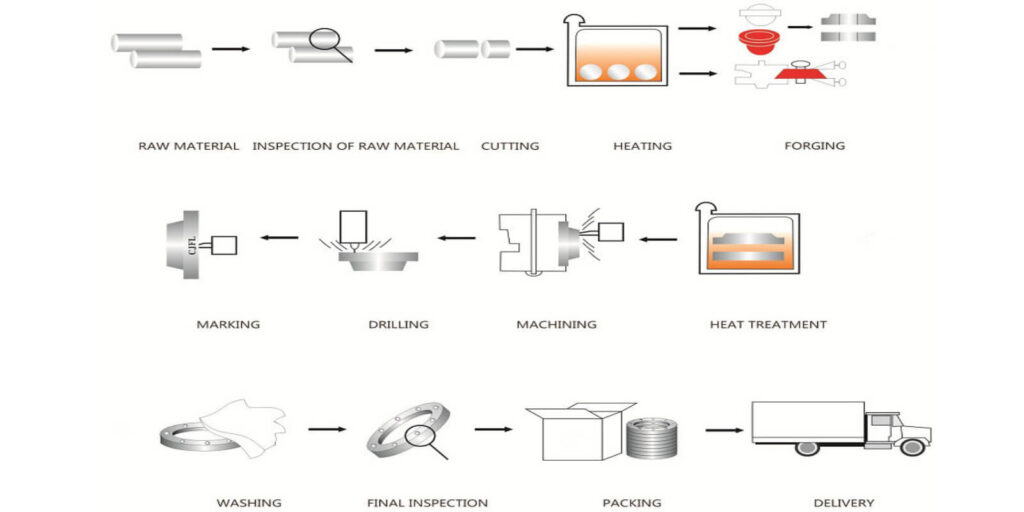

Our Manufacturing Process Of Alloy 28 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Alloy 20 Flanges

Our Material

Contact Us

Supplying World Wide