Alloy 20 Flanges

Home » Alloy 20 Flanges

ASME SB462 Alloy 20 Swrf Flange, ASTM B462 Alloy 20 Weld-Neck Flange-A-B, UNS N08020 Threaded Flange, ASME SB462 Alloy 20 Spades-Rings-Spacer Flanges, DIN 2.4660 Reducing Flange, ASME SB462 Alloy 20 RTJ Flange, DIN 2.4660 Lap-Joint Flange, DIN 2.4660 Weld-Neck Flange.

Renine Metalloys is a reputable international manufacturer and distributor of Alloy 20 Flanges. We design these flanges, strictly adhering to national and international quality standards. UNS N08020 Threaded Flange, distinguished by its unique composition of nickel, iron, and chromium, is further stabilized with niobium and enhanced with additions of copper and molybdenum. This distinctive alloy exhibits exceptional corrosion resistance, making it highly resilient to acidic, sulfuric, phosphoric, nitric acidic, and chloride-rich environments. Our portfolio encompasses varied flange types crafted from this alloy, ranging from slip-on, blind, and socket-weld to long weld neck, RTJ, and weld neck forms.

Recognized for their heightened resistance against pitting and crevice corrosion and seawater-induced rust, our DIN 2.4660 Reducing Flange possess exceptional tensile strength and an impressive elongation capability, even in acidic and seawater conditions. These flanges also showcase excellent toughness and resistivity, holding their own against harsh environmental conditions. Their impeccable chemical composition and mechanical features enable them to function effectively under high pressure and temperatures.

Renine Metalloys proudly offers an extensive array of DIN 2.4660 Flat Flange in various sizes, specifications, standards, and dimensions. Our provisions extend to bespoke specifications, serving the divergent needs of our clients. We take pride in crafting high-quality flanges that stand out for their durability, weldability, and fabricability. Our veteran manufacturing team employs superior-quality raw materials from trusted vendors to produce these flanges. All materials undergo rigorous pre-use testing to ensure the finished products are durable, low-maintenance, and long-lasting.

Leveraging cutting-edge techniques, state-of-the-art machinery, and advanced fabrication methods, our skilled workforce ensures the production of robust Alloy 20 Flanges. Our experts provide consistent supervision and guidance throughout every manufacturing stage. We maintain ample reserves of Alloy 20 Flanges to meet any emergency requirements readily.

At Renine Metalloys, our dedicated quality control team oversees each production phase, from inception to final delivery. Flanges undergo various destructive and non-destructive tests to validate their durability and ductility. Upon customer request, we arrange third-party inspections to guarantee product integrity further.

All client requirements, from timely, safe delivery to pristine product integrity, are our top priority. To ensure damage-free delivery, we implement all standard packaging practices and employ the fastest possible modes of transportation for prompt delivery.

Specification Of Alloy 20 Flanges

| Specifications | ASTM B462 / ASME SB462 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Alloy 20 Flanges

-

DIN 2.4660 Spectacle-Blind Flange US $20 - $25 / Kg

-

ASTM B462 Alloy 20 Square Flange US $23 - $24 / Kg

-

ASME SB462 Alloy 20 Swrf Flange US $22 - $23 / Kg

-

UNS N08020 Threaded Flange US $24 - $25 / Kg

-

DIN 2.4660 Weld-Neck Flange US $21 - $22 / Kg

Equivalent Grades Of Alloy 20 Flanges

| STANDARD | WERKSTOFF NR. | UNS | EN | AFNOR |

| Alloy 20 | 2.4660 | N08020 | NiCr20CuMo | Z2NCUD31-20AZ |

Chemical Composition Of Alloy 20 Flanges

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

Mechanical Properties Of Alloy 20 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi – 35,000, MPa – 241 | 30 % |

Different Types Of Alloy 20 Flanges

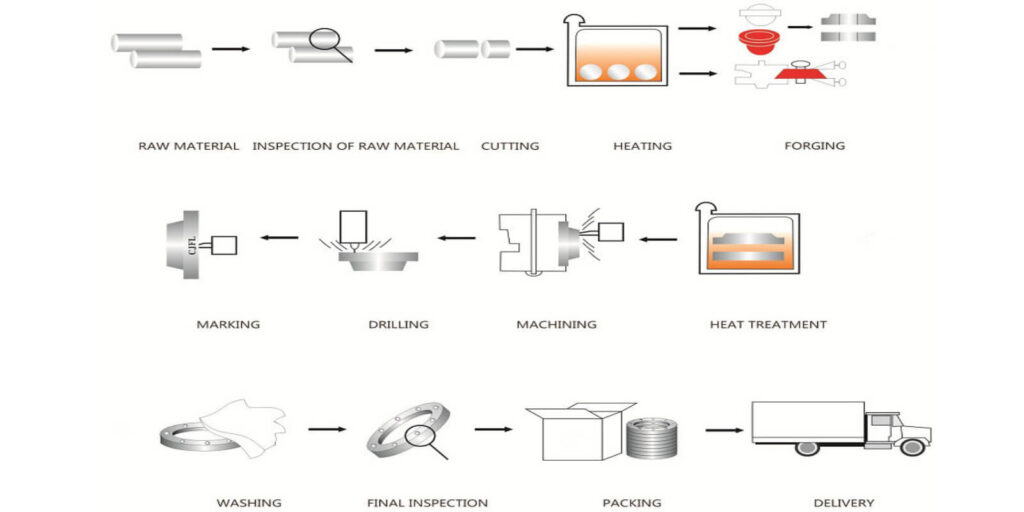

Our Manufacturing Process Of Alloy 20 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Alloy 20 Flanges

Our Material

Contact Us

Supplying World Wide