Duplex S32205 Flanges

Home » Duplex S32205 Flanges

DIN 1.4462 Forging Facing Flange, ANSI B16.5 Duplex S32205 Lap-Joint Flange, ANSI B16.5 Duplex S32205 Spectacle-Blind Flange, DIN 1.4462 Weldo-Nipo Flange, UNS S32205 Sorf Flange, ASTM A182 Duplex S32205 Square Flange, ANSI B16.5 Duplex S32205 Flat Flange, ASTM A182 Duplex S32205 Socket-Weld Flange.

Renine Metalloys LLP, a distinguished manufacturer, supplier, exporter, and trader, takes pride in delivering superior quality Duplex Steel UNS S32205 Flanges. Our production team employs premium-quality raw materials and alloys to construct these exemplary flanges. Composed of 22% chromium, 3% molybdenum, and 5-6% nickel, the ASTM A182 Duplex S32205 Square Flange boasts a unique chemical formulation that highly resists stress corrosion and superior mechanical strength under severe conditions. UNS S32205 Sorf Flange are excellently engineered and suitable for diverse industrial services requiring exceptional toughness and resistance.

Our line encompasses a variety of duplex steel flanges, including slip-on, weld neck, blind, RTJ, and long weld neck, among many others, each tailored to different standards and specifications. Our flanges are offered in an array of sizes, a range of surface finishes, and bespoke dimensions to meet the specific demands of our esteemed clients.

At Renine Metalloys LLP, our expert manufacturing team strictly adheres to the defined standards and set criteria when developing the ASTM A182 Duplex S32205 Socket-Weld Flange. We produce superior-quality flanges using the latest state-of-the-art equipment and modern fabrication techniques. Our development process aligns with stringent manufacturing norms and international industry standards. These flanges have wide usage in various industrial sectors, including petrochemicals, oil and gas processing, automotive, and chemical equipment. We offer flanges with impeccable resistance to chloride pitting and crevice corrosion, superior workability, prolonged service life, and precise dimensional accuracy.

In our quest for customer satisfaction, we strive to deliver defect-free and highly efficient DIN 1.4462 Forging Facing Flange. To ensure our products meet the highest quality, each flange is subjected to rigorous destructive and non-destructive tests under the careful inspection of our quality auditors at different junctures of the manufacturing process. This strict quality control procedure ensures no substandard products ever reach our esteemed clients. Our ANSI B16.5 Duplex S32205 Lap-Joint Flange are packaged to prevent damage during delivery, and we strictly adhere to the delivery deadlines set by our customers, using the fastest and most convenient delivery methods. Providing high-quality duplex steel flanges at competitive rates allows us to meet and exceed the expectations of our global clientele.

Specification Of Duplex S32205 Flanges

| Specifications | ASTM A182 / ASME SA182 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Duplex S32205 Flanges

-

DIN 1.4462 Expander Flange US $5 - $6 / Kg

-

UNS S32205 Nuts-Bolts Flange US $5 - $6 / Kg

-

ANSI B16.5 Duplex S32205 Flat Flange US $5 - $6 / Kg

-

ASTM A182 Duplex S32205 Forged Flange US $5 - $6 / Kg

-

DIN 1.4462 Forging Facing Flange US $5 - $6 / Kg

Equivalent Grades Of Duplex S32205 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex S32205 | 1.4462 | S31803 / S32205 |

Chemical Composition Of Duplex S32205 Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| 32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Mechanical Properties Of Duplex S32205 Flanges

| Density (g/cm 3) | Melting Point | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Different Types Of Duplex S32205 Flanges

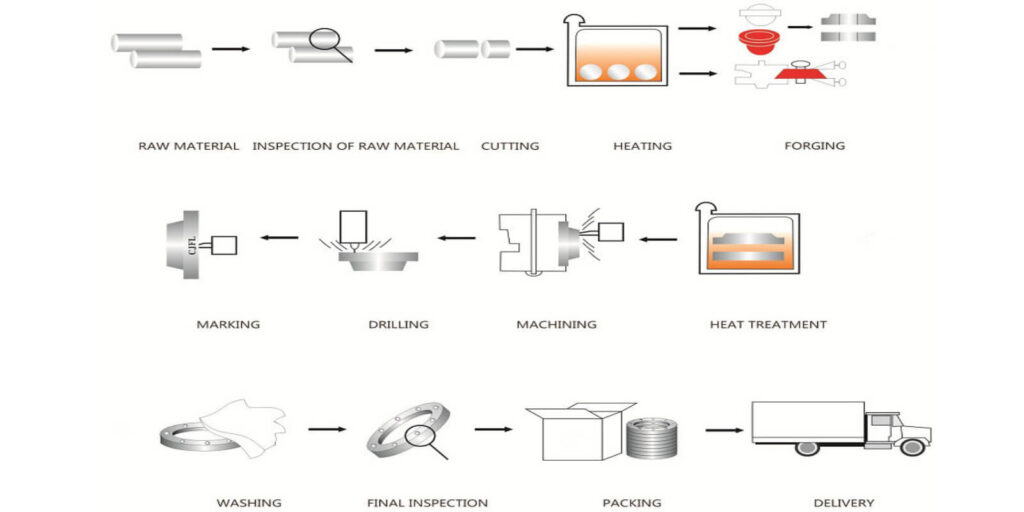

Our Manufacturing Process Of Duplex S32205 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Duplex Flanges

Our Material

Contact Us

Supplying World Wide