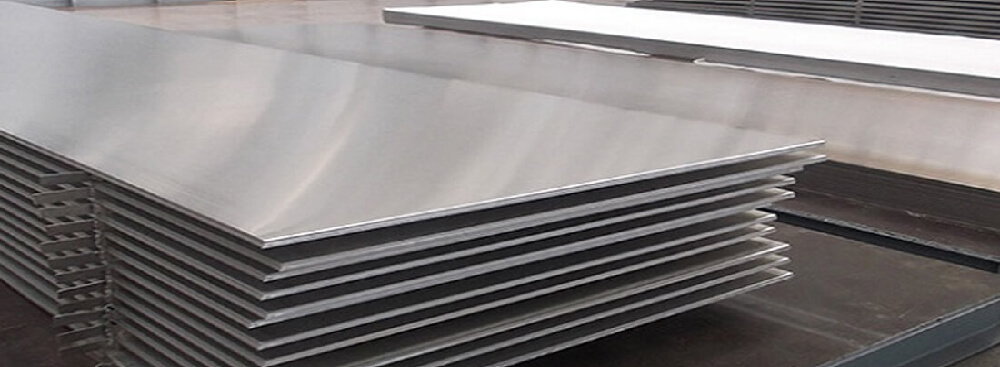

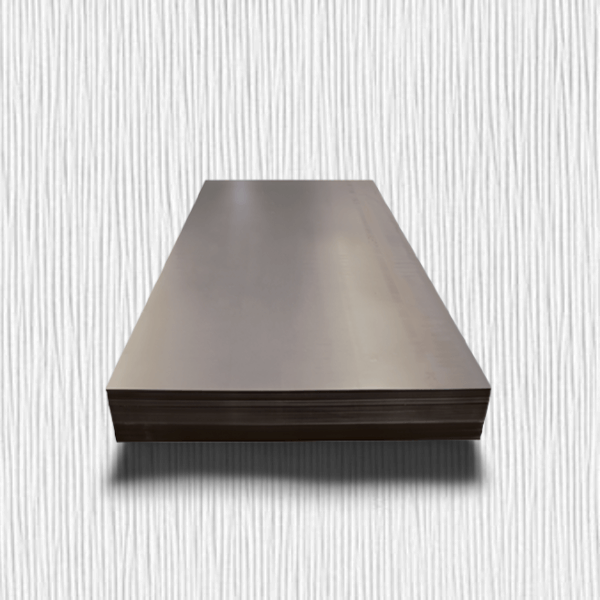

Alloy 20 Plate

Home » Alloy 20 Plate

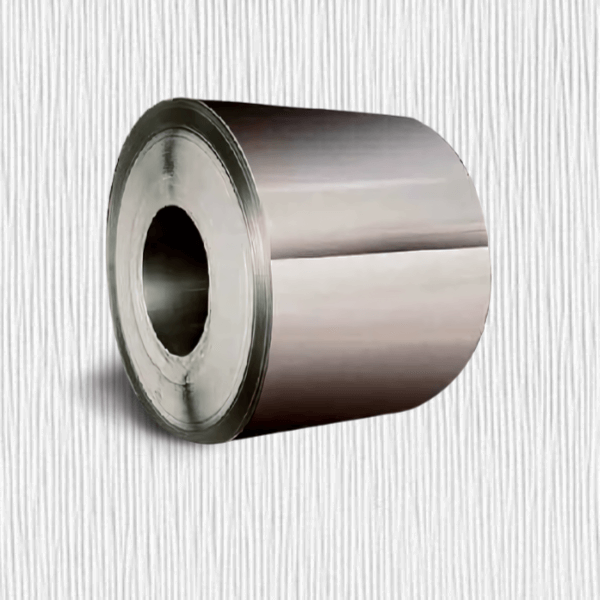

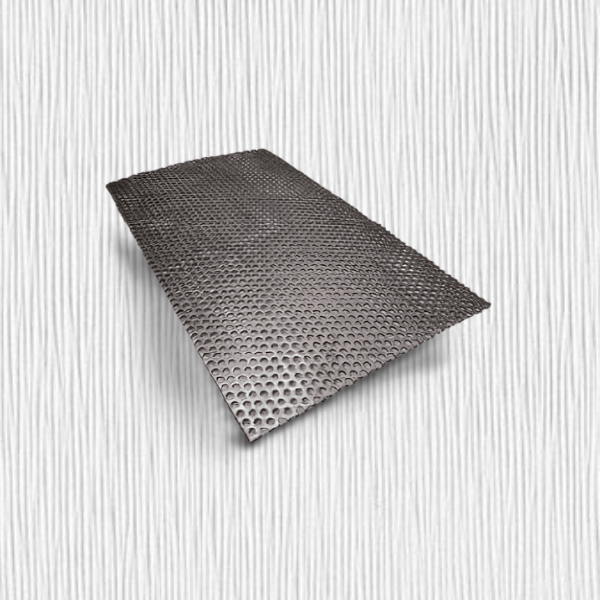

ASTM B463 Alloy 20 2B Finish, UNS N08020 Plain Sheet, ASTM B463 Alloy 20 Perforated Sheets, DIN 2.466 Hot Rolled Sheet, UNS N08020 Ring, DIN 2.466 Clad Plate, DIN 2.466 Shims, ASTM B463 Alloy 20 Sheets, UNS N08020 Circle, ASME SB463 Alloy 20 Rolls, ASME SB463 Alloy 20 Coil, ASME SB463 Alloy 20 Flats.

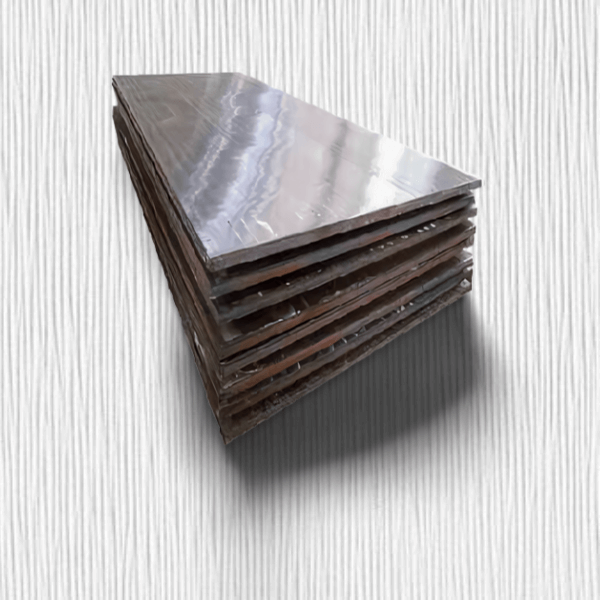

Alloy 20 is a type of stainless steel plate that contains high amounts of chromium and nickel. It also includes copper, manganese, silicon, nitrogen and carbon. This combination makes Alloy 20 very durable and resistant to corrosion. The properties that make this material useful across various industries include strength at high temperatures, resistance to oxidation and carburizing environments.

UNS N08020 Plain Sheet have higher creep rupture strength compared to standard austenitic grades. They also maintain their properties well after exposure to temperatures up to 1,650°F. The plates display exceptional resistance to both reducing and oxidizing acid solutions. This stainless steel resists corrosion even in environments with chlorides and other halides.

The material properties of Alloy 20 allow it to withstand stress for long durations. Parts made from UNS N08020 Cold Rolled Sheet retain good ductility after intermediate exposures. Components must handle force without fractures over time. This combination of creep strength and ductility benefits applications needing reliability.

Marine applications like desalination plants and oil platforms benefit from Alloy 20 in heat exchangers and evaporators. Resistance to chlorides in salt water prevents failures. Parts like fasteners, nuts and bolts made of Alloy 20 serve in subsea conditions without corrosion. The aerospace sector counts on properties like strength and oxidation resistance in jet engine components and exhaust systems. Durability at high temperatures becomes necessary.

The utility of DIN 2.466 Polished Plate from the retention of favourable properties over long durations, even with stress and heat. Equipment manufacturers choose Alloy 20 over other materials when they need reliability across decades. Parts show little deterioration even after years of strenuous use.

Alloy 20 delivers value when engineers need to build sturdy parts and mechanisms exposed to chemicals, fumes or ocean water. Reliable performance arises from the inherent qualities of this special stainless steel plate.

Specification Of Alloy 20 Plate

| Specification | ASTM B463 / ASME SB463 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

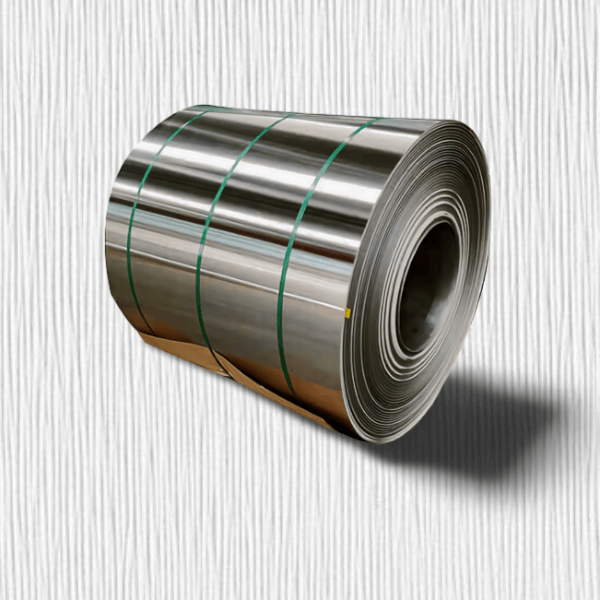

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

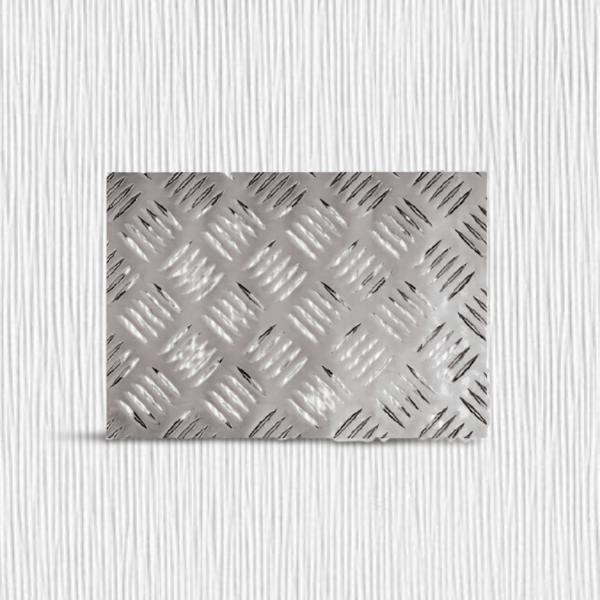

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Alloy 20 Plate

-

ASTM B463 Alloy 20 2B Finish US $20 - $25 / Kg

-

ASME SB463 Alloy 20 Coil US $23 - $24 / Kg

-

UNS N08020 Circle US $22 - $23 / Kg

-

DIN 2.466 Clad Plate US $24 - $25 / Kg

-

ASTM B463 Alloy 20 CR Sheet US $21 - $22 / Kg

Equivalent Grades Of Alloy 20 Plate

| STANDARD | WERKSTOFF NR. | UNS | EN | AFNOR |

| Alloy 20 | 2.4660 | N08020 | NiCr20CuMo | Z2NCUD31-20AZ |

Chemical Composition Of Alloy 20 Plate

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

Mechanical Properties Of Alloy 20 Plate

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi – 35,000, MPa – 241 | 30 % |

Different Types Of Alloy 20 Plate

Our Manufacturing Process Of Alloy 20 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Alloy 20 Plate

Our Material

Contact Us

Supplying World Wide