Waspaloy Flanges

Home » Waspaloy Flanges

DIN 2.4654 Socket-Weld Flange, DIN 2.4654 Ring-Type-Joint Flange, DIN 2.4654 Forged Flange, UNS N07001 Forging Facing Flange, UNS N07001 RTJ Flange, Waspaloy Sorf Flange, DIN 2.4654 Blind Flange, DIN 2.4654 Square Flange, UNS N07001 Weldo-Nipo Flange, Waspaloy Alloy Reducing Flange.

Renine Metalloys is a leading manufacturer, supplier, and exporter of superior-quality Waspaloy Flanges. In the fabrication process, we prioritize using premium alloys and raw materials to guarantee unparalleled quality production of flanges. Our diverse offerings encompass a wide range of sizes, shapes, dimensions, and lengths and can also be customized according to the specific requirements of our valued clients. Waspaloy Flanges, under our manufacture, garner significant demand across various industrial sectors due to their outstanding features.

Our extensive inventory incorporates flanges of great dimensional precision that adhere to rigorous standards. Offering these prime products at a reasonable price point, we ensure these flanges require minimal upkeep. Apart from their affordability and low maintenance requirements, these flanges demonstrate remarkable resistance to acidic and alkaline environments. In chloride solutions, they maintain resilience against pitting, stress corrosion, and crevice corrosion cracking.

At Rennie Metalloys, our production of DIN 2.4654 Forged Flange, leverages raw materials of the highest quality selected by our industry experts. With extensive experience and considerable expertise, they provide invaluable guidance to our workforce, ensuring the fabrication of top-tier UNS N07001 RTJ Flange within the stipulated timeframe. The production process employs the latest machinery and advanced equipment to guarantee the seamless integration of alloys, ultimately achieving an optimized end product.

To uphold the integrity of our products, we adhere strictly to international and national standards and specifications. Moreover, from the fabrication process to the final product, each step in the production line undergoes a series of destructive and non-destructive tests to verify their durability and strength. This stringent quality control occurs at our state-of-the-art production facility, ensuring adherence to stellar standards.

Besides quality assurance, we provide comprehensive reports and certifications as part of product documentation during the supply and export. Committed to efficient delivery, we rely on expedient shipping modes to promptly deliver Waspaloy Flanges to our esteemed customers.

Specification Of Waspaloy Flanges

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Waspaloy Flanges

-

Waspaloy Groove-Tongue Flange US $125 - $150 / Kg

-

Waspaloy Alloy Lap-Joint Flange US $130 - $135 / Kg

-

DIN 2.4654 Long-Weld-Neck Flange US $135 - $140 / Kg

-

UNS N07001 Loose Flange US $142 - $145 / Kg

-

Waspaloy Orifice Flange US $146 - $150 / Kg

Equivalent Grades Of Waspaloy Flanges

| Alloy Name | UNS | WNR. |

| Waspaloy | N07001 | 2.4654 |

Chemical Composition Of Waspaloy Flanges

| Cr | Ni | Mo | Co | Al | Ti | B | C | Zr | Fe | Mn | Si | P | S | Cu | |

| MIN | 18.00 | -- | 3.50 | 12.00 | 1.20 | 2.75 | 0.003 | 0.02 | 0.02 | -- | -- | -- | -- | -- | -- |

| MAX | 21.00 | Balance | 5.00 | 15.00 | 1.60 | 3.25 | 0.01 | 0.10 | 0.08 | 2.00 | 0.10 | 0.15 | 0.015 | 0.015 | 0.10 |

Different Types Of Waspaloy Flanges

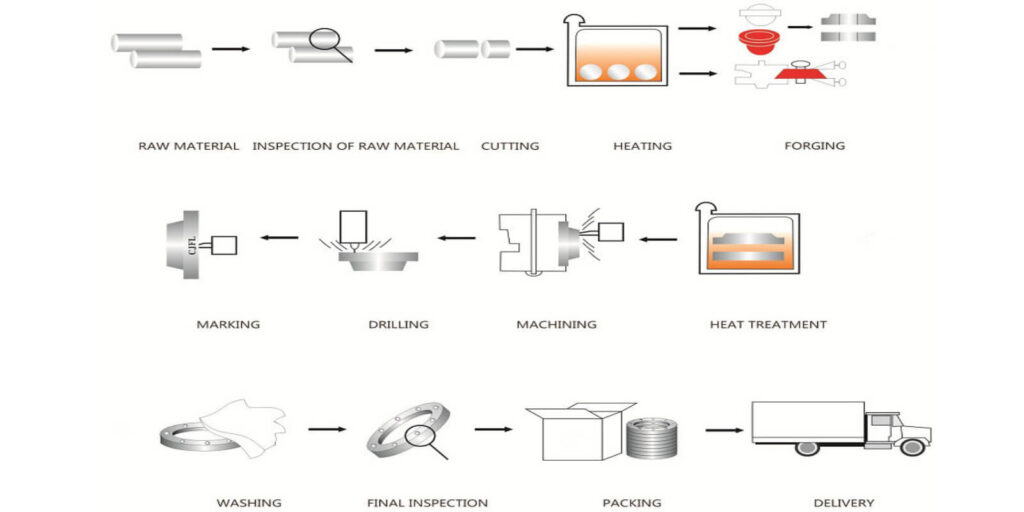

Our Manufacturing Process Of Waspaloy Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Waspaloy Flanges

Our Material

Contact Us

Supplying World Wide