Super Duplex 32760 Flanges

Home » Super Duplex 32760 Flanges

DIN 1.4501 Swrf Flange, UNS S32760 Nuts-Bolts Flange, DIN 1.4501 Weldo-Nipo Flange, ASTM A182 Super Duplex S32760 Forged Flange, ANSI B16.5 Super Duplex S32760 Spectacle-Blind Flange, ANSI B16.5 Super Duplex S32760 Slip-On Flange, DIN 1.4501 RTJ Flange, DIN 1.4501 Forging Facing Flange.

Renine Metalloys LLP is a leading and highly esteemed manufacturer and supplier of superior quality Super Duplex UNS S32760 Flanges. Super Duplex Steel, an alloy characterized by a synergistic ferritic-austenitic microstructure, incorporates chromium, nickel, and molybdenum, enhanced with copper, nitrogen, and tungsten. This rich chemical composition fosters high tensile strength and exceptional resistance to corrosion in challenging environments. Ideally suited to counter chloride-induced stress cracking and pitting, we utilize this alloy to fabricate all flange types, including blind, slip-on, weld-neck, long weld neck, and RTJ.

Our Super Duplex UNS S32760 Reducing Flanges offer excellent resistance against sulphide-stress corrosion cracking in sour-gas environments. Their enhanced impact strength and resistivity enable them to contend effectively with severe acidic and seawater environments. Demonstrating extraordinary durability and toughness, these Super Duplex Steel Flanges become indispensable for operations across various sectors, such as oil and gas, petrochemical, and heat exchanger industries.

Equipped with an experienced and proficient workforce, Renine MetalloysLLP crafts WNR 1.4410 Super Duplex Steel Weld Neck Flanges with top-quality, thoroughly inspected raw material. These flanges, designed meticulously in compliance with international quality standards, offer impact resistance and durability across a broad temperature spectrum, from elevated to low.

The Super Duplex Slip on Flanges are celebrated for their myriad attributes: precision, exact fine finish, easy installation, superior weldability and workability, and extended service life. Our flanges’ unparalleled cost-effectiveness and performance significantly contribute to their high demand. Produced at our advanced fabrication unit using state-of-the-art technology and machinery, each flange is formed under the stringent supervision of our expert team throughout the manufacturing process.

Within Renine Metalloys LLP, we view quality assurance as integral to delivering irreproachably superior products. Various quality tests are conducted to evaluate the performance and quality of Super Duplex Steel UNS S32760 Flanges. Our quality experts verify multiple parameters and properties of flanges throughout the manufacturing process.

We maintain extensive inventory stocks of Super Duplex Steel UNS S32760 Flanges to adequately fulfil global industrial demand, even on an emergent basis. After rigorous quality checks, we pack the flanges using sturdy packaging to mitigate potential transportation damage. With swift and convenient shipping options, we take pride in timely deliveries to our esteemed clients.

Specification Of Super Duplex 32760 Flanges

| Specifications | ASTM A182 / ASME SA182 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Super Duplex 32760 Flanges

-

ASTM A182 Super Duplex S32760 Blind Flange US $12 - $15 / Kg

-

DIN 1.4501 Expander Flange US $13 - $15 / Kg

-

UNS S32760 Nuts-Bolts Flange US $13 - $14 / Kg

-

ANSI B16.5 Super Duplex S32760 Flat Flange US $14 - $15 / Kg

-

ASTM A182 Super Duplex S32760 Forged Flange US $12 - $15 / Kg

Equivalent Grades Of Super Duplex 32760 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex S32760 | 1.4501 | S32760 |

Chemical Composition Of Super Duplex 32760 Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Properties Of Super Duplex 32760 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000, MPa – 800 | Psi – 80000, MPa – 550 | 15 % |

Different Types Of Super Duplex 32760 Flanges

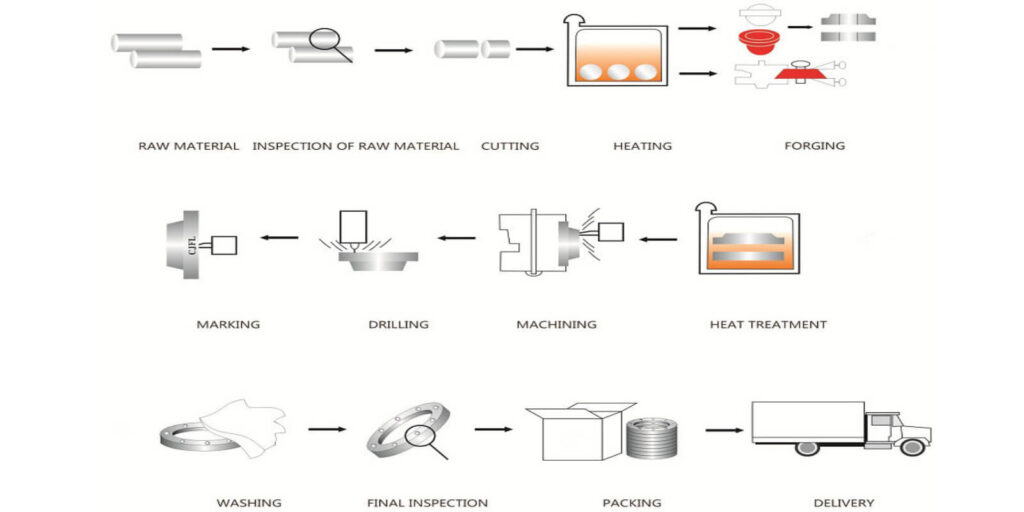

Our Manufacturing Process Of Super Duplex 32760 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Super Duplex Flanges

Our Material

Contact Us

Supplying World Wide