Nickel 200 Flanges

Home » Nickel 200 Flanges

DIN 2.4066 Orifice Flange, DIN 2.4066 Wnrf Flange, DIN 2.4066 Screwed Flange, JIS NW 2200 Reducing Flange, UNS N02200 Weldo-Nipo Flange, UNS N02200 Swrf Flange, DIN 2.4066 Groove-Tongue Flange, DIN 2.4066 Nuts-Bolts Flange, ASTM B564 Nickel 200 Weld-Neck Flange-A-B, ASTM B564 Nickel 200 Blind Flange.

Renine Metalloys, a distinguished leader in the manufacturing, supply, and export of Nickel 200 Flanges, consistently strives to cater to our customer’s urgent requirements by maintaining a robust stock inventory. Our ASTM B564 Nickel 200 Blind Flange are highly sought after across various sectors due to their precise dimensionality and enhanced efficiency. In line with our commitment to customer-centric service, we offer these flanges in diverse dimensions, lengths, and sizes. Additionally, our product offerings extend to bespoke solutions tailored to your specific requirements in terms of shape and size, all at competitively reasonable prices.

Our UNS N02200 Swrf Flange are crafted from the purest metals to ensure unparalleled durability and strength. This sharp focus on the choice of materials, which includes nickel, chromium, copper, and molybdenum, contributes to the flanges’ remarkable yield strength, superior tensile strength, and optimal corrosion resistance. Nickel Alloy Welding Neck Flanges are not only corrosion-resistant but also suitable for the construction of a variety of parts and structures.

Renine Metalloys’s commitment as the top-quality JIS NW 2200 Reducing Flange manufacture. Leveraging state-of-the-art tools and techniques, our expert team, equipped with extensive knowledge and expertise, selects premium raw materials to maintain superior quality standards.

We hold ourselves to the highest levels of product quality and quantity while adhering to international and national standards and specifications. Our relentless pursuit of excellence drives us to provide the most fitting products for diverse industrial applications. Understanding and meeting our clients’ needs is essential to our operations as we continuously strive to improve product quality.

The integrity of DIN 2.4066 Groove-Tongue Flange is ensured through a thorough series of destructive and non-destructive tests performed by our expert team before product delivery. Once satisfied with the final product’s quality standards, we employ top-quality packaging materials to ensure the flanges reach our clients in mint condition.

At Renine Metalloys, we empower our clients with detailed test certifications and assure the safe and timely delivery of flanges to our client’s doorsteps. Your satisfaction is our ultimate goal, and we do not compromise to ensure it.

Specification Of Nickel 200 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Nickel 200 Flanges

-

UNS N02200 Expander Flange US $44 - $50 / Kg

-

DIN 2.4066 Nuts-Bolts Flange US $46 - $47 / Kg

-

JIS NW 2200 Flat Flange US $44 - $46 / Kg

-

ASTM B564 Nickel 200 Forged Flange US $47 - $50 / Kg

-

UNS N02200 Forging Facing Flange US $45 - $49 / Kg

Equivalent Grades Of Nickel 200 Flanges

| STANDARD | UNS | WNR. | JIS | EN |

| Nickel 200 | N02200 | 2.4066 | NW 2200 | Ni 99.2 |

Chemical Composition Of Nickel 200 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Of Nickel 200 Flanges

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Different Types Of Nickel 200 Flanges

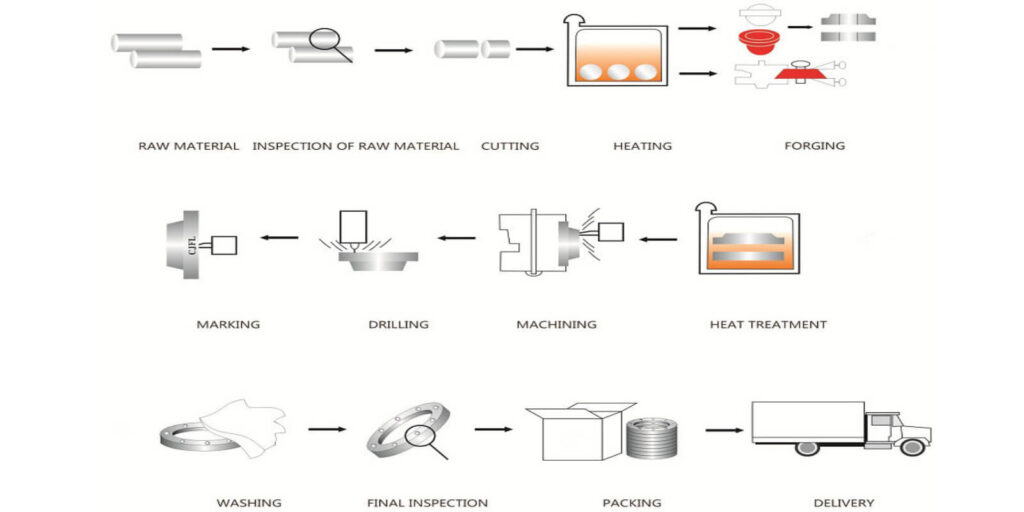

Our Manufacturing Process Of Nickel 200 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Nickel Flanges

Our Material

Contact Us

Supplying World Wide