Inconel 725 Flanges

Home » Inconel 725 Flanges

ASME SB564 Inconel 725 Weld-Neck Flange, UNS N07725 Threaded Flange, ASTM B564 Inconel 725 Groove-Tongue Flange, ASME SB564 Inconel 725 Square Flange, ASTM B564 Inconel 725 Ring-Type-Joint Flange, UNS N07725 Orifice Flange, ASME SB564 Inconel 725 Reducing Flange, ASTM B564 Inconel 725 Slip-On Flange.

Renine Metalloys LLP is a distinguished manufacturer, supplier, stockist, and exporter of premium-quality Inconel 725 Flanges. Tailored to specific industrial needs, these flanges are available in various sizes and forms. Our catalogue carries an exhaustive range of flange types – from weld neck, blind flanges, and socket weld neck to slip-on, ring joint, lap joint, and beyond – all matched to diverse industry requirements.

Ensure seamless connection between pipes and other industrial equipment, courtesy of our world-class flanges. Offered in varied grades, dimensions, finishes, and specifications, these flanges are the product of adhering to stringent international quality standards and diverse design specifications.

Inconel 725, characterized by a unique blend of nickel, chromium, molybdenum alloys, aluminium, niobium, and titanium, offers exceptional chemical and mechanical properties, including remarkable yield and tensile strength heated temperatures and commendable hardenability credited to the titanium content. Thanks to these properties, Inconel 725 is the preferred choice for flange fabrication.

Inconel 725 Flanges Our flanges boast excellent resistance to corrosion, pitting, oxidation, and crevice corrosion in intensely corrosive environments and stand rust-free in acidic, chloride, and reductive atmospheres. Engineered for superb workability, weldability, and machinability, are ideal for brackish and seawater applications.

Renine Metalloys LLP extends its expertise to deliver a comprehensive range of Super Alloy Inconel 725 (UNS N07725) to industries as wide-ranging as marine, pollution control, aerospace, construction, auto, and chemical sectors. Priding ourselves on our flanges’ high durability, performance, and ease of fabrication, we craft each piece to withstand high pressure and temperature conditions. Guaranteeing the finest craftsmanship, our team employs only the prime raw materials for fabricating these flanges. Moreover, our Inconel 725 Flanges are available in a wide range of standards and specifications and are offered at impressively competitive rates to cater to a broader audience.

Each of our ASTM A182 Alloy 725 Inconel Flange undergoes rigorous testing processes by our quality experts in our state-of-the-art manufacturing unit. Involving both destructive and non-destructive examinations, we ensure every aspect of the flange meets our quality parameters. Committed to excellence, we guarantee the delivery of defect-free and highly efficient flanges to all our clients.

Post-testing, we take great care to pack the Inconel 725 Flanges suitably to safeguard them from delivery-related damages. Using the most secure and swift modes of transportation, we ensure these flanges are delivered to our global customers within the agreed timeframe. A fulfilling customer experience is our ultimate endeavour.

Specification Of Inconel 725 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Inconel 725 Flanges

-

ASTM B564 Inconel 725 Flat Flange US $44 - $50 / Kg

-

UNS N07725 Forged Flange US $46 - $47 / Kg

-

ASME SB564 Inconel 725 Forging Facing Flange US $44 - $46 / Kg

-

ASTM B564 Inconel 725 Groove-Tongue Flange US $47 - $50 / Kg

-

UNS N07725 Lap-Joint Flange US $45 - $49 / Kg

Equivalent Grades Of Inconel 725 Flanges

| STANDARD | UNS | WNR. |

| Inconel 725 | N06725 | 2.4856 |

Chemical Composition Of Inconel 725 Flanges

| Elements | Nickel, Ni | Chromium, Cr | Iron, Fe | Molybdenum, Mo | Niobium, Nb (Columbium, Cb) | Titanium, Ti | Aluminum, Al | Manganese, Mn | Silicon, Si | Carbon, C | Phosphorous, P | Sulfur, S |

| Content (%) | 55 – 59 | 19 – 22.5 | 9 | 7 – 9.50 | 2.75 – 4 | 1 – 1.70 | 0.35 | 0.35 | 0.2 | 0.03 | 0.015 | 0.01 |

Mechanical Properties Of Inconel 725 Flanges

| Properties | Tensile strength | Yield strength (@0.2%) | Modulus of elasticity | Poissons ratio | Elongation at break | Hardness, Rockwell C |

| Metric | 855 MPa | 427 MPa | 204 GPa | 0.31 | 57% | 5 |

| Imperial | 124000 psi | 62000 psi | 29600 ksi | 0.31 | 57% | 5 |

Different Types Of Inconel 725 Flanges

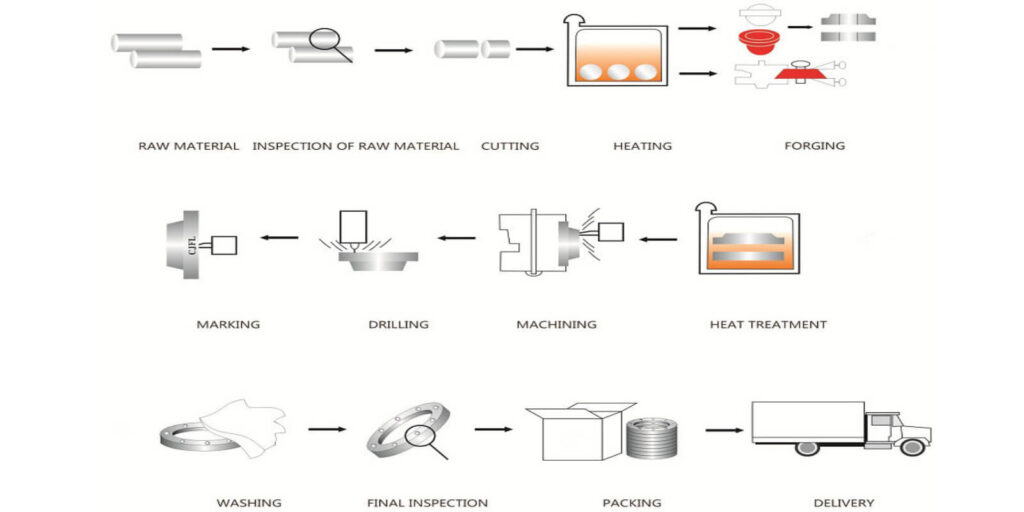

Our Manufacturing Process Of Inconel 725 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Flanges

Our Material

Contact Us

Supplying World Wide