Inconel 718 Flanges

Home » Inconel 718 Flanges

DIN 2.4668 Wnrf Flange, ASME SB564 Inconel 718 Flat Flange, DIN 2.4668 Nuts-Bolts Flange, ASME SB564 Inconel 718 Reducing Flange, ASTM B564 Inconel 718 Square Flange, ASTM B564 Inconel 718 Ring-Type-Joint Flange, ASTM B564 Inconel 718 Weld-Neck Flange-A-B, UNS N07718 Expander Flange.

Renine Metalloys LLP stands as a preeminent manufacturer, supplier, wholesaler, and exporter of Inconel 718 Flanges, a product superbly designed to meet the finest quality standards. It offers manifold flange styles, including weld neck, blind flanges, socket weld neck, slip-on, ring joint, and lap joint. These models accommodate many needs across diverse industrial sectors, reinforcing our reputation for versatility and adaptability.

Our production team strictly adheres to international quality benchmarks and detailed specifications, producing precise, reliable products. Our ASTM B564 Inconel 718 Square Flange are pivotal in industrial settings: solidly fastening two pipes or pieces of equipment. Available in varying grades, dimensions, finishes, and specifications, we cater to an extensive range of requirements.

ASME SB564 Inconel 718 Flat Flange is a favoured grade, mainly due to its unique composition of nickel, chromium, and molybdenum alloys, refined with aluminium, niobium, and titanium elements. This blend yields staggering chemical and mechanical properties, providing unrivalled yield and tensile strength, even under high temperatures. The added titanium offers remarkable hardening capability. This particular alloy is the material of choice for manufacturing flanges thanks to its impressive resilience to corrosion, pitting, oxidization, and crevice corrosion, even in severely corrosive environments. Moreover, the presence of nickel and chromium bonds effectively opposes chloride-iron stress. Our flanges maintain their immunity to rust, whether exposed to acidic, chloride, or reducing atmospheres.

Inconel 718 Flanges are valued for their superior workability, weldability, and machinability, making them perfect for applications in brackish and seawater conditions. Renine Metalloys capitalizes on these advantageous properties, providing a broad scope of UNS N07718 Expander Flange to sectors such as marine, pollution control, aerospace, construction, automotive, chemical, and several others. Our flanges are recognized for high durability, formidable performance, and effortless fabrication and withstand demanding pressure and temperature conditions.

Our commitment to quality is underpinned by the selection of premium raw materials, ensuring the excellence of our final products. To ensure maximum accessibility, we offer Inconel 718 Flanges in various standards and specifications to our global clientele at cost-competitive rates.

As part of our stringent quality control protocol, every ASTM B564 Inconel 718 Weld-Neck Flange-A-B undergoes rigorous tests. Conducted in our state-of-the-art manufacturing facility by seasoned quality control personnel, this thorough testing regimen includes destructive and non-destructive evaluations, gauging a range of flange parameters. Our mission is to deliver defect-free and high-performing flanges to our customers, and we ensure they meet this standard. Once testing is complete, each batch of DIN 2.4668 Nuts-Bolts Flange is carefully packed to prevent any in-transit damage. We utilize the most secure and efficient delivery methods to ensure that our flanges reach our clients promptly within the agreed timeframe.

Specification Of Inconel 718 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Inconel 718 Flanges

-

ASME SB564 Inconel 718 Spectacle-Blind Flange US $44 - $50 / Kg

-

ASTM B564 Inconel 718 Square Flange US $46 - $47 / Kg

-

UNS N07718 Swrf Flange US $44 - $46 / Kg

-

DIN 2.4668 Threaded Flange US $47 - $50 / Kg

-

ASME SB564 Inconel 718 Weld-Neck Flange US $45 - $49 / Kg

Equivalent Grades Of Inconel 718 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

Chemical Composition Of Inconel 718 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | - | 50.00 - 55.00 | 17.00 - 21.00 |

Mechanical Properties Of Inconel 718 Flanges

| Ultimate Tensile Strength, psi | .2% Yield Strength psi | Elongation % | Hardness Rockwell B |

| 135,000 | 70,000 | 45 | 100 |

Different Types Of Inconel 718 Flanges

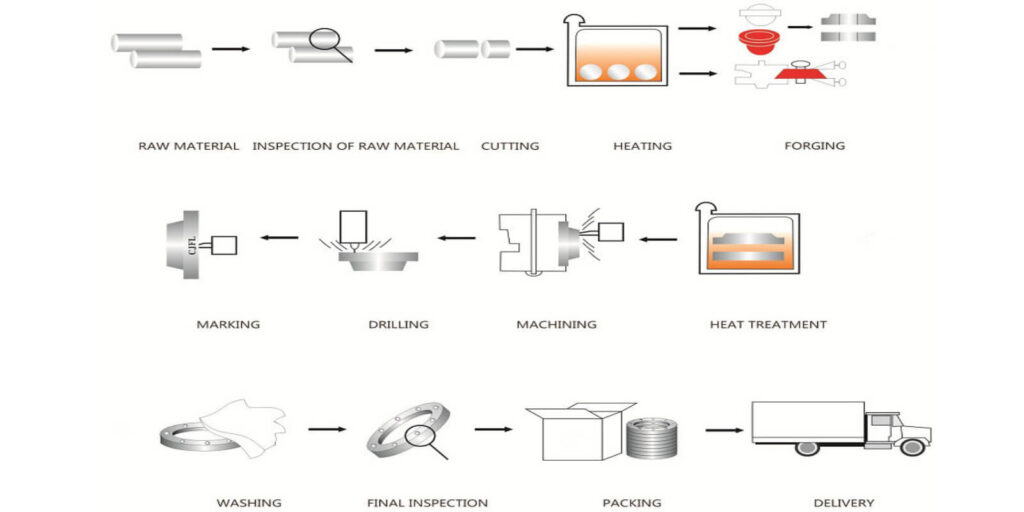

Our Manufacturing Process Of Inconel 718 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Flanges

Our Material

Contact Us

Supplying World Wide