Inconel 600 Flanges

Home » Inconel 600 Flanges

ASTM B564 Inconel 600 Weld-Neck Flange-A-B, ASTM B564 Inconel 600 Forged Flange, UNS N06600 Swrf Flange, JIS NW 600 Lap-Joint Flange, UNS N06600 RTJ Flange, ASTM B564 Inconel 600 Square Flange, UNS N06600 Loose Flange, DIN 2.4816 Sorf Flange, JIS NW 600 Slip-On Flange.

Renine Metalloys LLP, a prominent industry leader, has made significant strides in producing Inconel 600 Flanges. Recognized for accommodating the diverse needs of a global clientele, the company also specializes in fabricating tailor-made ASTM B564 Inconel 600 Forged Flange. These products, manufactured in line with national and international quality standards, are available in an impressive range of sizes, diameters, and thicknesses. Our comprehensive and meticulous machining and tooling processes for each product reflect our commitment to providing optimal operational comfort for the end-user.

Our in-house team of quality experts, production professionals, and dedicated staff provide pivotal support throughout every stage of product development, utilizing their expertise, skills, knowledge, and innovative ideas to deliver top-tier products. The trust and satisfaction we have garnered from our customer base is a testament to our team’s pivotal role in maintaining our high standards.

In producing UNS N06600 Swrf Flange, we employ Inconel 600, an alloy of nickel and chromium procured from reputable suppliers. Boasting premier physical, chemical, and mechanical attributes, Inconel 600 equips our finished products with robust endurance against extreme temperatures, corrosive environments, and various solvents. Our testing procedure scrutinizes the raw material for parameters such as strength, toughness, weldability, and performance under fabrication processes.

Following detailed test results analysis and subsequent comparison with established standards, we commence the production process. This method safeguards consistent product quality across all stages of manufacture. At Renine Metalloys LLP, we manufacture an array of JIS NW 600 Slip-On Flange under the expert supervision of our seasoned professionals, ensuring a final product with unparalleled anti-corrosive and cracking-resistant properties capable of performing in adverse operational conditions.

Additionally, every batch of UNS N06600 Loose Flange undergoes rigorous testing for resistivity against hydrating solutions. Backed by our production specialists, we adeptly handle any production challenges that may arise, with their expert guidance instrumental in enhancing our production procedures and fostering an innovative and research-driven approach. With an impressive inventory stocked with extensive product volume, Renine Metalloys stands ready to meet our client’s immediate and diverse needs.

Specification Of Inconel 600 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Inconel 600 Flanges

-

ASTM B564 Inconel 600 Forged Flange US $44 - $50 / Kg

-

UNS N06600 Forging Facing Flange US $46 - $47 / Kg

-

DIN 2.4816 Groove-Tongue Flange US $44 - $46 / Kg

-

JIS NW 600 Lap-Joint Flange US $47 - $50 / Kg

-

ASTM B564 Inconel 600 Long-Weld-Neck Flange US $45 - $49 / Kg

Equivalent Grades Of Inconel 600 Flanges

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | NiCr15Fe | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 |

Chemical Composition Of Inconel 600 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015 max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Mechanical Properties Of Inconel 600 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | 655 MPa, 95000 psi | 310 MPa, 45000 psi | 45 % |

Different Types Of Inconel 600 Flanges

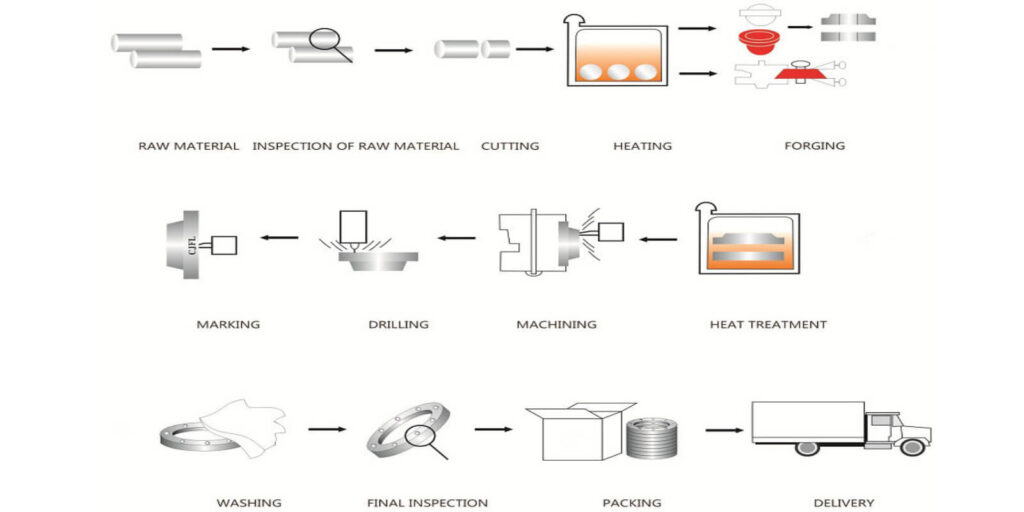

Our Manufacturing Process Of Inconel 600 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Flanges

Our Material

Contact Us

Supplying World Wide