Incoloy 825 Plate

Home » Incoloy 825 Plate

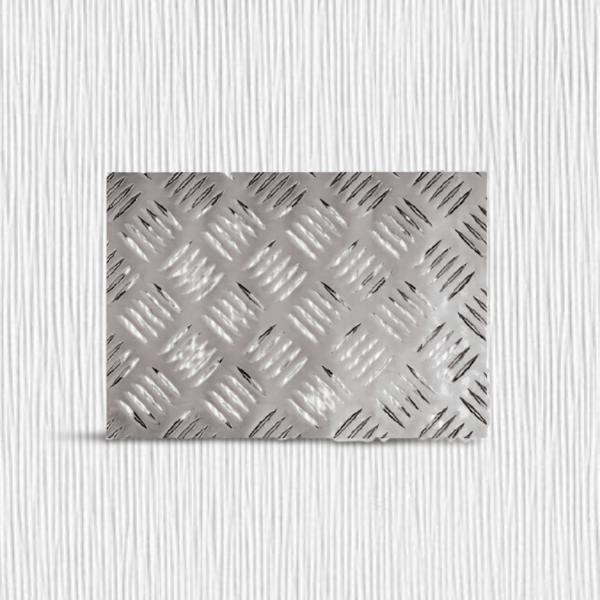

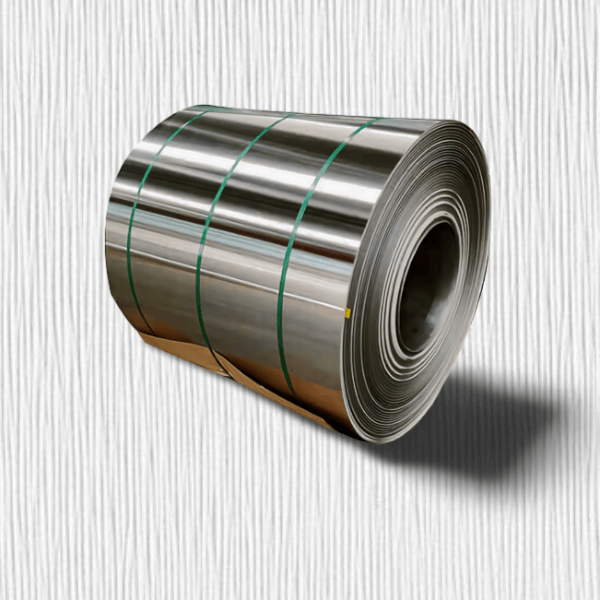

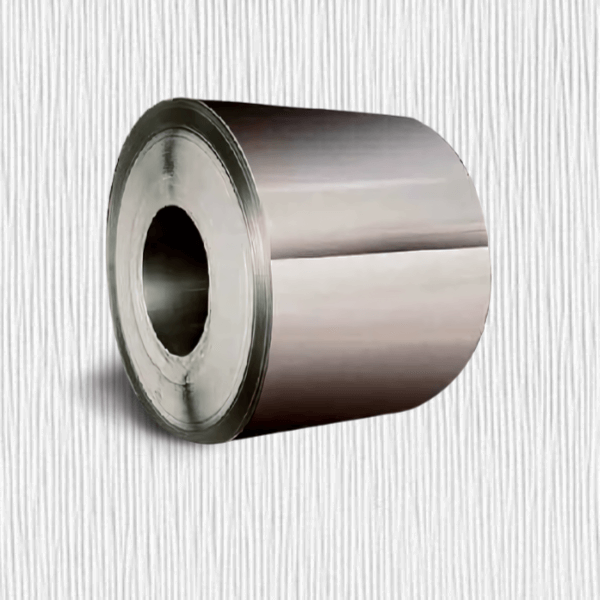

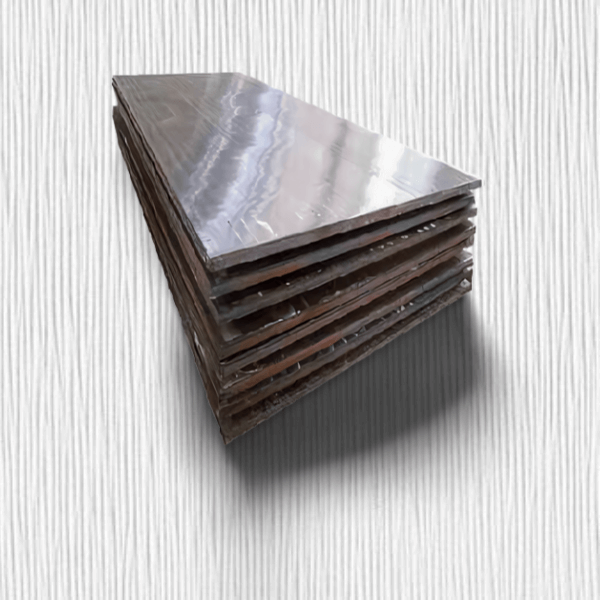

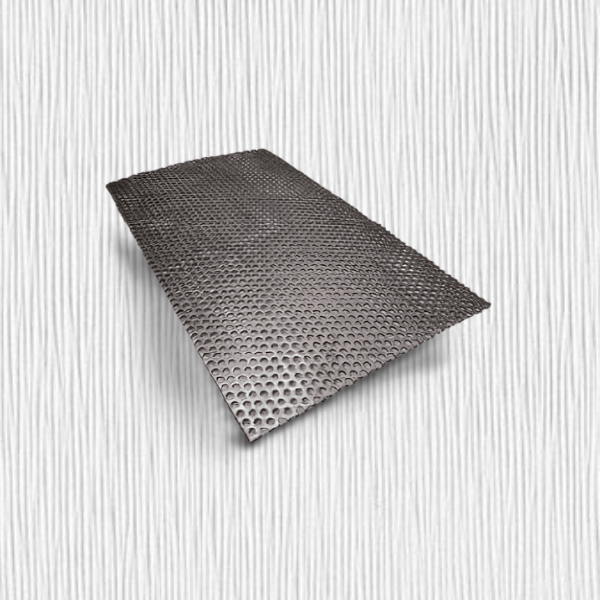

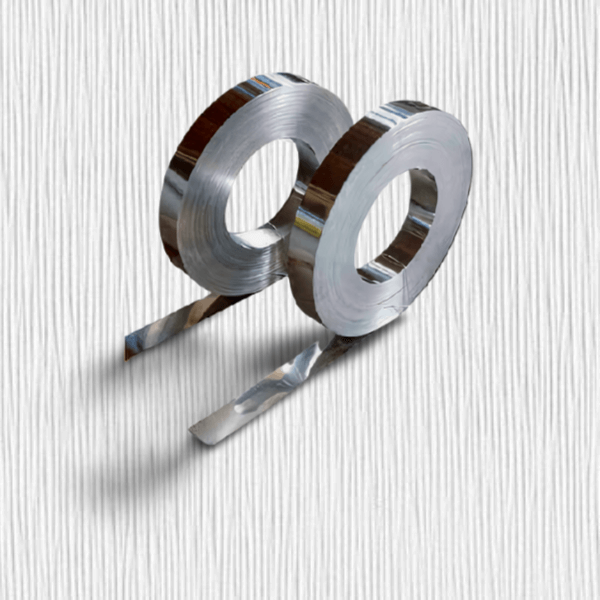

UNS N08825 Plain Sheet, UNS N08825 Foil Sheet, ASTM B424 Incoloy 825 CR Sheet, UNS N08825 Circle, ASME SB424 Incoloy 825 Coil, ASME SB424 Incoloy 825 Plate, ASTM B424 Incoloy 825 Sheets, DIN 2.4858 Hot Rolled Sheet.

Incoloy 825 is an iron-nickel-chromium alloy that is known for its exceptional corrosion resistance and strength. This alloy was designed to perform in harsh environments and is commonly used in chemical processing, oil and gas production, pollution control equipment, and even marine applications.

The plate form of DIN 2.4858 Trim Strip provides outstanding durability and versatility. Incoloy 825 plates can withstand high temperatures, resist corrosion, and maintain their strength in demanding industrial uses. This makes it well-suited for cladding, welded fabrication, and other applications requiring corrosion resistance and high-temperature strength.

Some key properties and advantages of the Incoloy 825 plate include:

- Excellent corrosion resistance – Incoloy 825 has superior resistance to pitting, crevice corrosion, stress corrosion cracking, and more even in acidic conditions. This is because of the alloy elements like nickel and chromium. The plate resists corrosion from acids like hydrochloric, sulfuric, acetic, and phosphoric.

- High strength – The plate has good tensile and creep rupture strength due to its nickel-iron matrix. It maintains high strength even at continuously high temperatures. The yield strength of Incoloy 825 is around 400 MPa.

- Good weldability – The chromium and iron content gives the Incoloy 825 plate satisfactory weldability using common fusion and resistance techniques. Post-weld annealing further enhances weld strength.

- Low thermal expansion – The alloy has much lower expansion compared to austenitic steels, minimizing distortion issues in weldments and other applications. The expansion rate is around half that of type 304 stainless steel.

- Excellent oxidation resistance – The ability to resist oxidation and scaling means Incoloy 825 plates retain strength and corrosion resistance at high temperatures. It is usable for continuous service up to 1150°F.

- Non-magnetic permeability – The Incoloy 825 plate provides non-magnetic permeability, an important factor for certain critical chemical processing applications.

Incoloy 825 plate provides unmatched performance where both heat and corrosion resistance are prime considerations. Incoloy 825 plate will continue to be a trusted material across harsh industrial environments.

Specification Of Incoloy 825 Plate

| Specifications | ASTM B424 / ASME SB424 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Incoloy 825 Plate

-

ASTM B424 Incoloy 825 2B Finish US $20 - $25 / Kg

-

ASME SB424 Incoloy 825 Coil US $23 - $24 / Kg

-

UNS N08825 Circle US $22 - $23 / Kg

-

DIN 2.4858 Clad Plate US $24 - $25 / Kg

-

ASTM B424 Incoloy 825 CR Sheet US $21 - $22 / Kg

Equivalent Grades Of Incoloy 825 Plate

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Incoloy 825 | N08825 | 2.4858 | NC22DNB4M | NiCr22Mo9Nb | NCF 825 | NA 21 | ЭП703 | ЭИ602 |

Chemical Composition Of Incoloy 825 Plate

| Grade | C | Mn | Si | S | Al | Ti | Fe | Ni | Cr |

| Incoloy 825 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | 0.40 max | 0.40 max | 5.0 max | 58.0 min | 20.0 - 23.0 |

Mechanical Properties Of Incoloy 825 Plate

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi - 1,35,000 , MPa -930 | Psi - 75,000 , MPa - 517 | 42.5 % |

Different Types Of Incoloy 825 Plate

Our Manufacturing Process Of Incoloy 825 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Incoloy Plate

Our Material

Contact Us

Supplying World Wide