Incoloy 800H Plate

Home » Incoloy 800H Plate

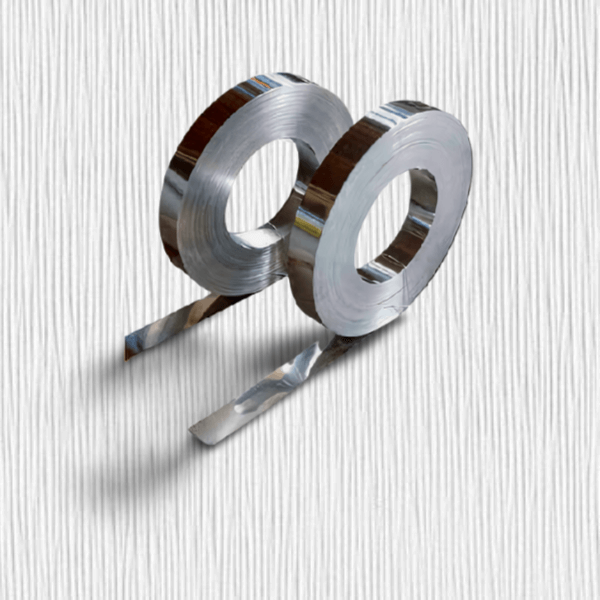

ASME SB409 Incoloy 800H Plate, DIN 1.4958 Shims, UNS N08810 Plain Sheet, ASTM B409 Incoloy 800H Perforated Sheets, DIN 1.4958 Clad Plate, ASME SB409 Incoloy 800H Flats, ASTM B409 Incoloy 800H Sheets, UNS N08810 Foil Sheet, ASME SB409 Incoloy 800H Coil.

Incoloy 800H is a nickel-iron-chromium alloy that is known for its high strength and excellent corrosion resistance properties. This superalloy plate provides outstanding performance in high-temperature applications up to 1150°F (621°C).

The nickel content in ASME B409 Incoloy 800H Rolled Coils contributes to its resistance to corrosion and oxidation. The chromium adds strength and hardness, which makes this alloy ideal for high-pressure and high-temperature conditions. The small amounts of aluminum and titanium in the composition serve to improve the mechanical properties and creep resistance.

The UNS N08810 Flats has a tightly controlled carbon content, which gives it greater ductility and impact strength compared to other nickel-iron alloys. The carbon level also minimizes the precipitation of graphite on the grain boundaries, which can reduce corrosion resistance.

The excellent resistance to carburization and oxidizing atmospheres makes Incoloy 800H well suited for heat treating and annealing furnace applications. It is commonly used for high-temperature heat exchangers, reformer tubes, retorts, muffles and other fired heater components.

ASME SB409 Incoloy 800H Hot Rolled Sheet has good ductility and is readily fabricated using conventional methods used for stainless steel. It can be formed, stamped, drawn and machined. All commercial methods can weld the alloy plates, sheets and tubes. Post Weld annealing is recommended when this material is welded.

During heating cycles, the scaling resistance of Incoloy 800H is better than austenitic stainless steels such as 304 or 316. It does not need heavy chrome oxide coatings. This keeps maintenance costs lower.

ASME SB409 Incoloy 800H Slitting Coil is an iron-nickel-chromium alloy with remarkable strength and corrosion resistance at high temperatures. It withstands carburizing and oxidizing conditions. The excellent fabrication properties allow use in critical applications across demanding industries. With properties optimized for long service life, Incoloy 800H continues to be the material of choice for severe environments.

Specification Of Incoloy 800H Plate

| Specifications | ASTM B409 / ASME SB409 |

| Dimensional specification | ASTM, ASME and API |

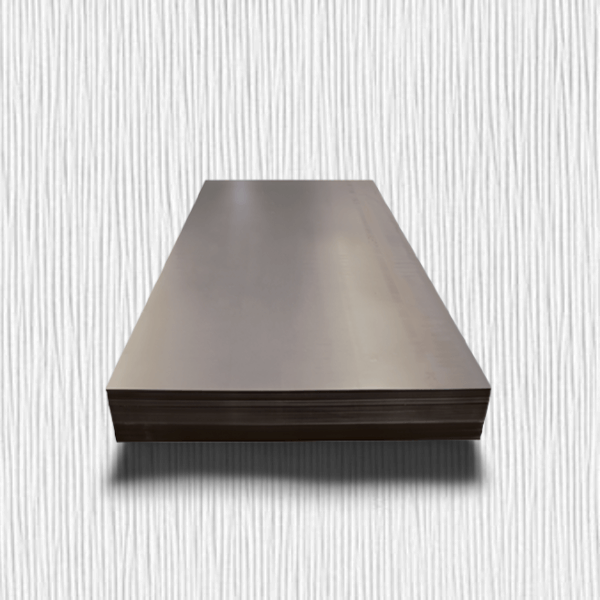

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

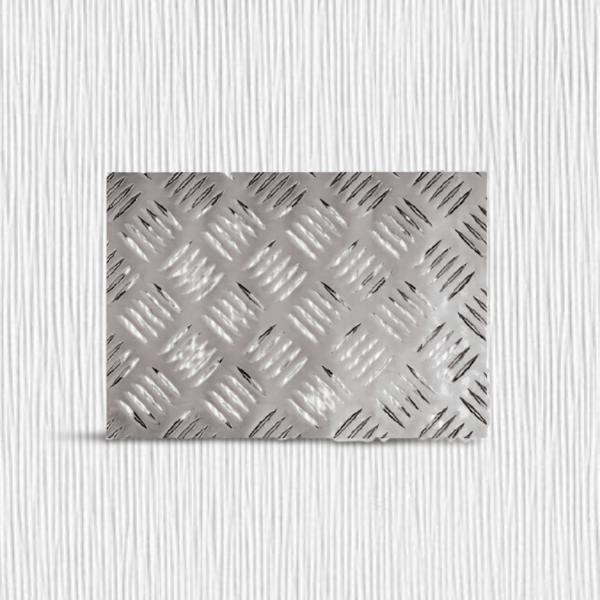

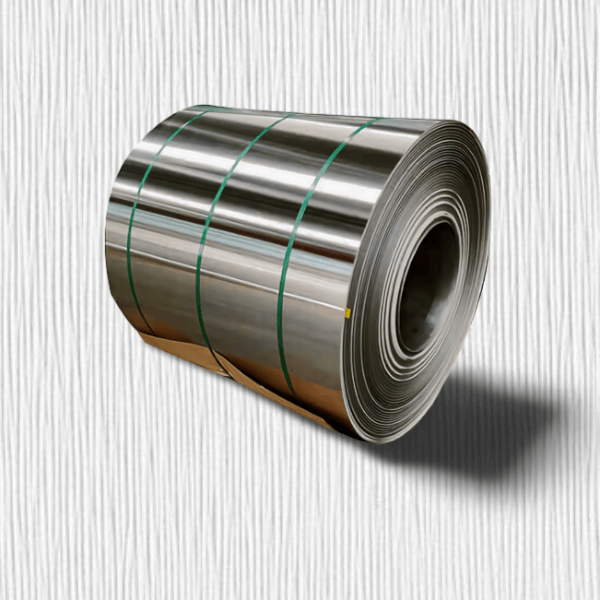

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Incoloy 800H Plate

-

ASTM B409 Incoloy 800H 2B Finish US $20 - $25 / Kg

-

ASME SB409 Incoloy 800H Coil US $23 - $24 / Kg

-

UNS N08810 Circle US $22 - $23 / Kg

-

DIN 1.4958 Clad Plate US $24 - $25 / Kg

-

ASTM B409 Incoloy 800H CR Sheet US $21 - $22 / Kg

Equivalent Grades Of Incoloy 800H Plate

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

Chemical Composition Of Incoloy 800H Plate

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

Mechanical Properties Of Incoloy 800H Plate

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1350-1400 ℃ | Psi - 75,000 , MPa -520 | Psi - 30,000 , MPa - 205 | 30 - 35 % |

Different Types Of Incoloy 800H Plate

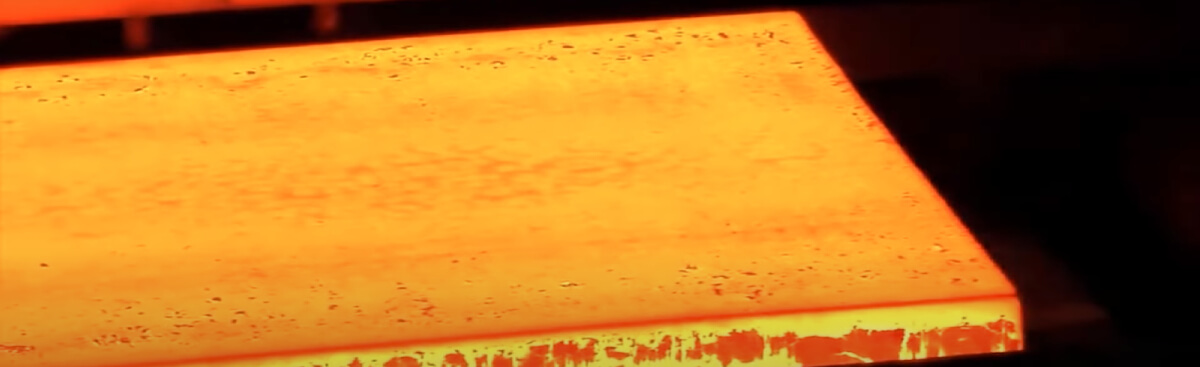

Our Manufacturing Process Of Incoloy 800H Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Incoloy Plate

Our Material

Contact Us

Supplying World Wide