Incoloy 800H Forged Fitting

Home » Incoloy 800H Forged Fitting

ASTM B564 Incoloy 800H Forged Threaded Plug, UNS N08810 Forged Half Coupling, DIN 1.4958 Forged Full Coupling, ASTM B564 Incoloy 800H Forged Threaded Pipe Nipples, ASME SB564 Incoloy 800H Forged Union, DIN 1.4958 Forged Threaded Lateral Tee, ASTM B564 Incoloy 800H Forged Cap, ASME SB564 Incoloy 800H Forged Cross, UNS N08810 Forged Hex Plug, DIN 1.4958 Forged Sockolet Fitting.

Incoloy 800H forged fittings are created using a modified version of a high nickel alloy, designed to deliver performance, at high temperatures and better stability. Made of nickel, chromium with amounts of iron, aluminum and titanium Incoloy 800H aims to provide mechanical properties and resistance to corrosion in demanding industrial settings.

These precise Incoloy 800H fittings boast strength and durability for applications needing resistance against thermal fatigue, creep and stress corrosion cracking. The forging process enhances the grain structure of the fittings ensuring they can endure temperatures and thermal changes reliably. This makes them suitable for industries like chemical processing, power generation and furnace components.

One notable characteristic of Incoloy 800H forged fittings is their resistance to carburization and intergranular corrosion. This feature guarantees longevity in environments exposed to high temperature gases and harsh chemicals. Due to this corrosion resistance along with oxidation protection these fittings are favored for components requiring defense against corrosive substances.

Engineered to retain their properties at elevated temperatures up to, around 1800°F (982°C) ASME SB564 Incoloy 800H Forged Union maintain performance without compromise. Incoloy 800H stands out for its ability to withstand temperatures and maintain thermal stability making it a popular choice, for applications that need strength and dependability in extreme heat environments.

The weldability and machinability of DIN 1.4958 Forged Threaded Lateral Tee add to their versatility during installation and maintenance tasks allowing integration into piping systems. Their compatibility with welding techniques ensures connection and operational efficiency across various industrial settings.

To sum up Incoloy 800H forged fittings excel in high temperature performance, thermal stability and corrosion resistance offering a solution for applications that demand durability and reliability in conditions. With their features and proven performance in environments Incoloy 800H forged fittings are a preferred option, for industries prioritizing top notch performance and long term functionality.

Specification Of Incoloy 800H Forged Fitting

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Dimensions | ASME 16.11, MSS SP-79,83,95,97,BS 3799 |

| Size | 1/2"NB TO 4"NB IN |

| Class / Pressure | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | SOCKET WELD (S/W) & SCREWED (SCRD), Threaded – NPT, BSP, BSPT |

Price List Of Incoloy 800H Forged Fitting

-

ASTM B564 Incoloy 800H Forged Cap US $20 - $25 / Kg

-

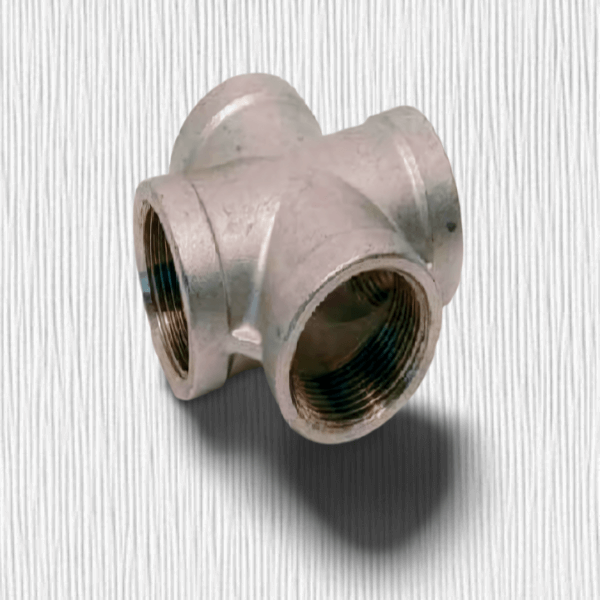

ASME SB564 Incoloy 800H Forged Cross US $23 - $24 / Kg

-

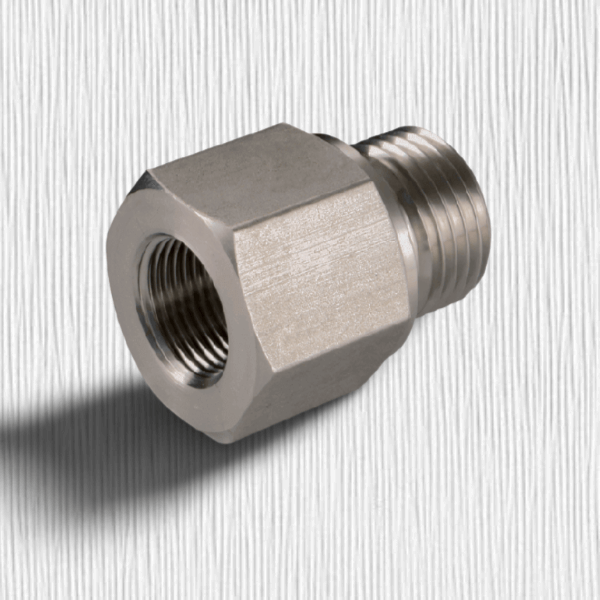

UNS N08810 Forged Adapter Fitting US $22 - $23 / Kg

-

DIN 1.4958 Forged Full Coupling US $24 - $25 / Kg

-

ASTM B564 Incoloy 800H Forged Tee US $21 - $22 / Kg

Equivalent Grades Of Incoloy 800H Forged Fitting

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

Chemical Composition Of Incoloy 800H Forged Fitting

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

Mechanical Properties Of Incoloy 800H Forged Fitting

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1350-1400 ℃ | Psi - 75,000 , MPa -520 | Psi - 30,000 , MPa - 205 | 30 - 35 % |

Different Types Of Incoloy 800H Forged Fitting

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Incoloy Forged Fitting

Our Material

Contact Us

Supplying World Wide