Duplex S32205 Plate

Home » Duplex S32205 Plate

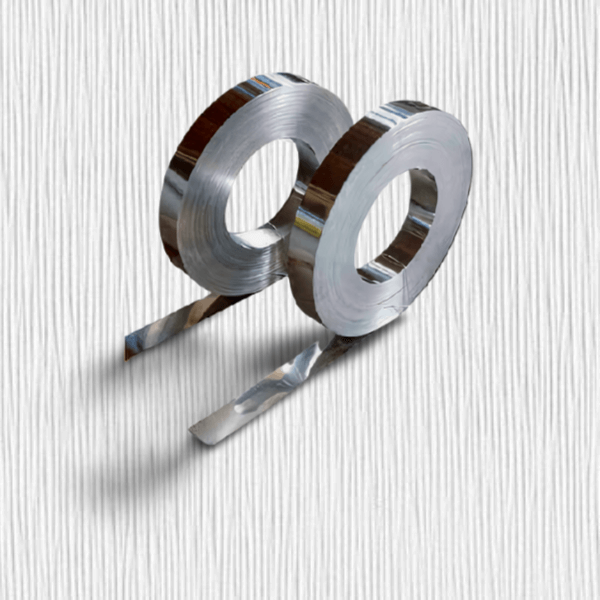

UNS S32205 Ring, ASTM A 240 Duplex S32205 2B Finish, DIN 1.4462 Clad Plate, DIN 1.4462 Shims, UNS S32205 Foil Sheet, UNS S32205 Plain Sheet, ASME SA 240 Duplex S32205 Rolls, UNS S32205 Circle, ASTM A 240 Duplex S32205 Sheets, ASME SA 240 Duplex S32205 Plate, DIN 1.4462 Hot Rolled Sheet.

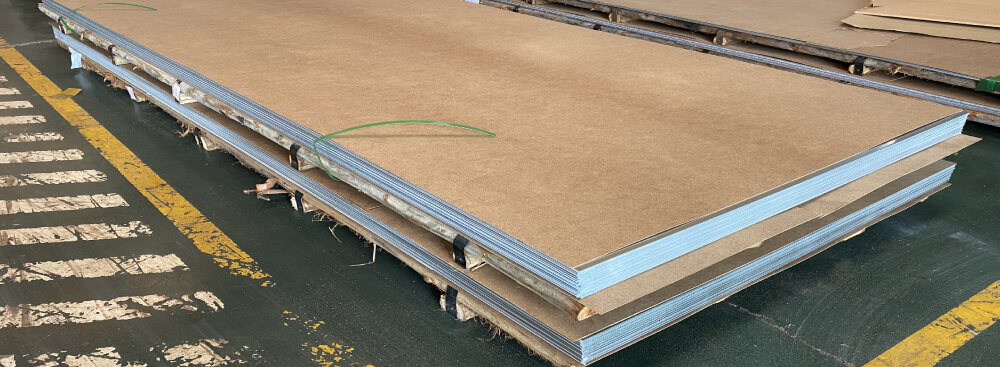

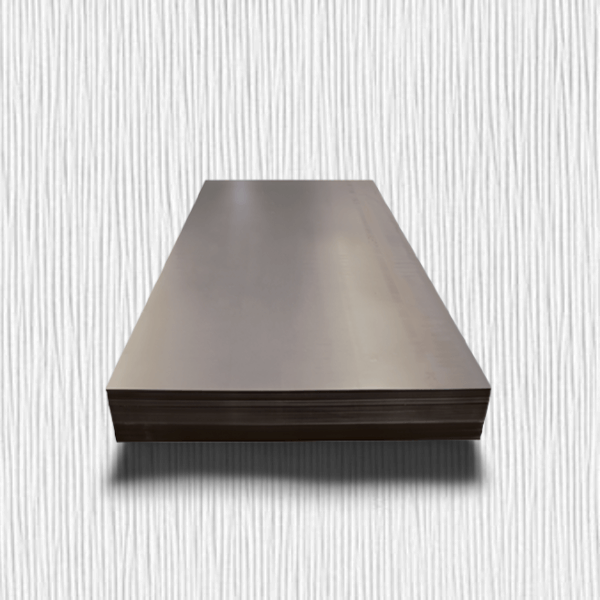

The Duplex S32205 Plate is a stainless steel plate offering impressive strength, corrosion and wear resistance. Made to exacting standards for superior quality, it has a range of useful mechanical properties and physical qualities that make it suitable for many industrial, engineering and construction applications.

An austenitic, dull polishing UNS S32205 Plain Sheet stainless steel has a two-phase grade of 22% Cr, 5% Ni, and 3% Mo duplex composition for optimized performance in harsh or corrosive environments. It resists deterioration at high temperatures and pressures as well as preventing build-up of rust and chemical compounds. With low thermal expansion, it retains excellent workability at both high and cryogenic temperatures

With a density of around 7.75 g/cm3 and a melting range of 1500-1540°C, Duplex Steel UNS S32205 Plates & Sheets can withstand some very extreme operating conditions and is commonly used for heavy machine parts, marine equipment and spiral heat exchangers, as well as oil, petrochemical and other processing plants.

It also has good metallurgical stability and will not suffer pitting or crevice corrosion like other 300 or 400-series steels. The two-phase mixed austenitic and ferritic structure allows it to exhibit superior toughness and ductility compared to other stainless grades. It has a higher yield and tensile strength than 316L, even though elongation and reduction in the area meet or exceed those of the 316/316L plate.

Machinability is fairly moderate but extra care must be taken when welding to avoid the risk of carbide precipitation and nitrogen loss which can lead to corrosion. Preheating thick plates, control of interpass temperature and post-weld stress relieving or annealing are often required to avoid hot or cold cracking.

The combination of added molybdenum and chromium gives the S32205 grade its enhanced corrosion resistance in chlorides, acetic acid, seawater and others. Tests confirm superior resistance to crevice corrosion and better resistance to stress corrosion cracking over 316L.

Renine Metalloys LLP is a trustworthy 2205 duplex stainless steel plate Supplier & Manufacturer of all Duplex products. Contact us for more details on the Duplex 2205 price per kg

.

Specification Of Duplex S32205 Plate

| Specifications | ASTM A240 / ASME SA240 |

| Dimensional specification | JIS, AISI, ASTM, GB, DIN, EN, etc |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Thickness | 4mm-100mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

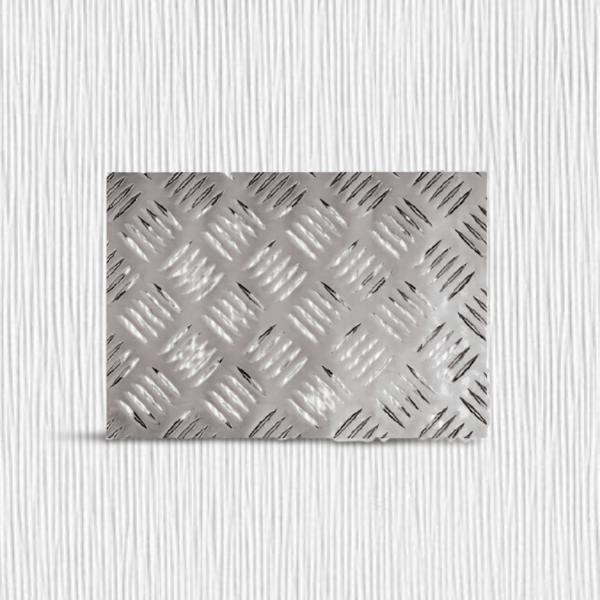

| Surface Finish | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc. |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

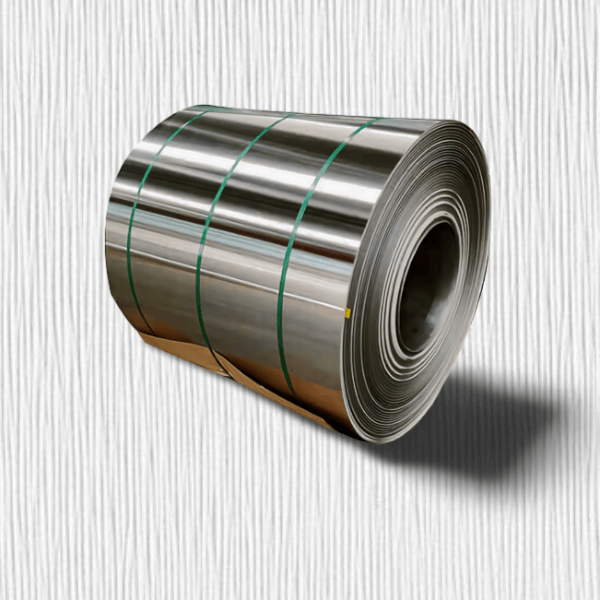

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Surface Finish | No.1, No.4, No.8 Mirror Finish, 2B |

Price List Of Duplex S32205 Plate

-

ASTM A 240 Duplex S32205 2B Finish US $5 - $6 / Kg

-

ASME SA 240 Duplex S32205 Coil US $5 - $6 / Kg

-

UNS S32205 Circle US $5 - $6 / Kg

-

DIN 1.4462 Clad Plate US $5 - $6 / Kg

-

ASTM A 240 Duplex S32205 CR Sheet US $5 - $6 / Kg

Equivalent Grades Of Duplex S32205 Plate

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex S32205 | 1.4462 | S31803 / S32205 |

Chemical Composition Of Duplex S32205 Plate

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| 32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Mechanical Properties Of Duplex S32205 Plate

| Density (g/cm 3) | Melting Point | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Different Types Of Duplex S32205 Plate

Our Manufacturing Process Of Duplex S32205 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Duplex Plate

Our Material

Contact Us

Supplying World Wide