Alloy 28 Plate

Home » Alloy 28 Plate

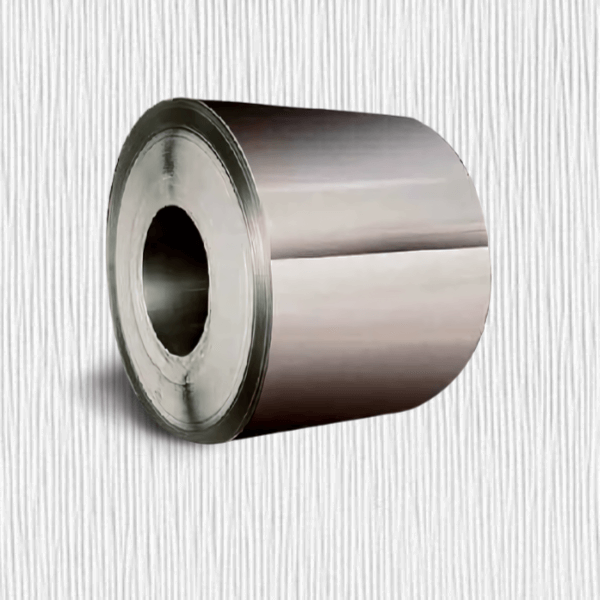

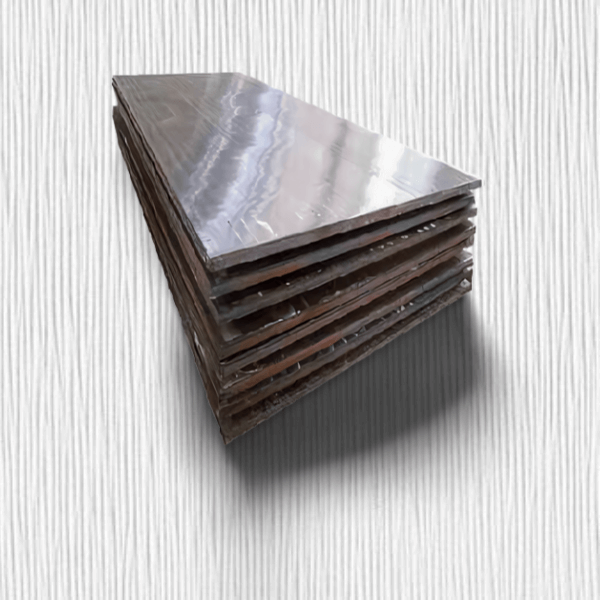

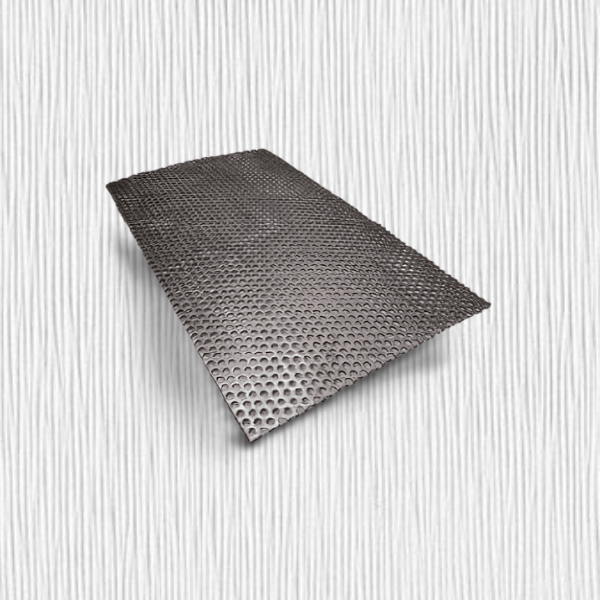

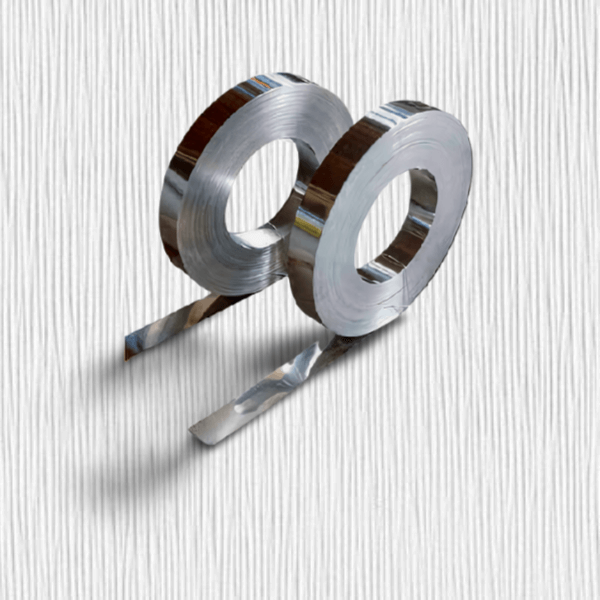

ASTM B463 Alloy 28 Perforated Sheets, UNS N08028 Plain Sheet, DIN 1.4563 Hot Rolled Sheet, UNS N08028 Circle, ASME SB463 Alloy 28 Flats, UNS N08028 Foil Sheet, ASME SB463 Alloy 28 Rolls, DIN 1.4563 Clad Plate, ASME SB463 Alloy 28 Plate, UNS N08028 Ring.

Alloy 28 is a special kind of metal that is made by combining other metals such as nickel, chromium, and iron. This metal plate is known for being very strong while also resisting corrosion or rust. Unlike regular steel, UNS N08028 Plain Sheet can withstand very high temperatures without losing its strength or changing shapes.

The plate is constructed with careful control over the percentages of different metals to create its unique properties. A large portion of the plate contains nickel and chromium, which gives Alloy 28 its ability to endure heat and oxidation. Smaller amounts of other metals like carbon, manganese, silicon, and phosphorus are also added to enhance the durability and workability of the material. The 28 refers to the percentage of nickel and chromium present in the alloy.

Due to its strength and resistance, DIN 1.4563 CR Sheet finds many uses in demanding industries and applications. The petrochemical sector relies on it to fabricate equipment that must maintain stability despite exposure to extreme environments. Aircraft and aerospace manufacturers use Alloy 28 plates to construct components that experience friction and fluctuating pressures. The medical field takes advantage of its anti-corrosive abilities to create surgical tools and implants that must uphold strict hygienic standards.

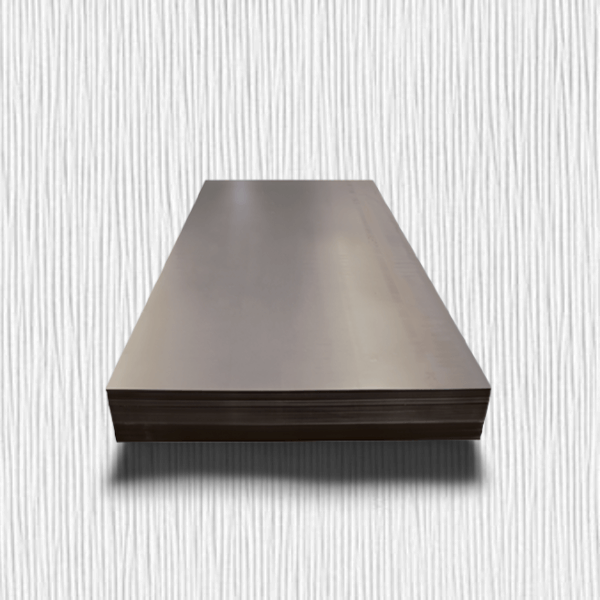

With care taken during production, the ASME SB463 Alloy 28 Finish Sheet achieves impressive uniformity in its chemical makeup and physical dimensions. Consistency in the distribution of its metallic compounds translates to optimal mechanical properties across the plate. Precise sizing with tight tolerances allows the material to be integrated into larger assemblies where fit is critical. Strict quality control ensures reliable performance is maintained for safety in sensitive applications.

The material properties of Alloy 28 do come at an increased cost over regular steel or alloy plates. However, the long lifespan and effectiveness it brings in hot and acidic environments can offset the higher initial pricing with proper care and maintenance, equipment built using Alloy 28 Plate can deliver reliable, long-lasting performance in harsh chemical processing, pollution control, pulp/paper production and other demanding industries. Its unique capabilities make it an important engineering material for critical applications.

Specification Of Alloy 28 Plate

| Specification | ASTM B463 / ASME SB463 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

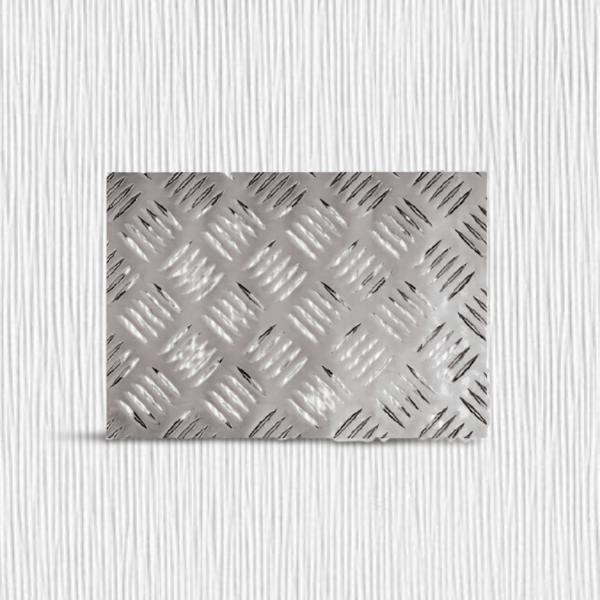

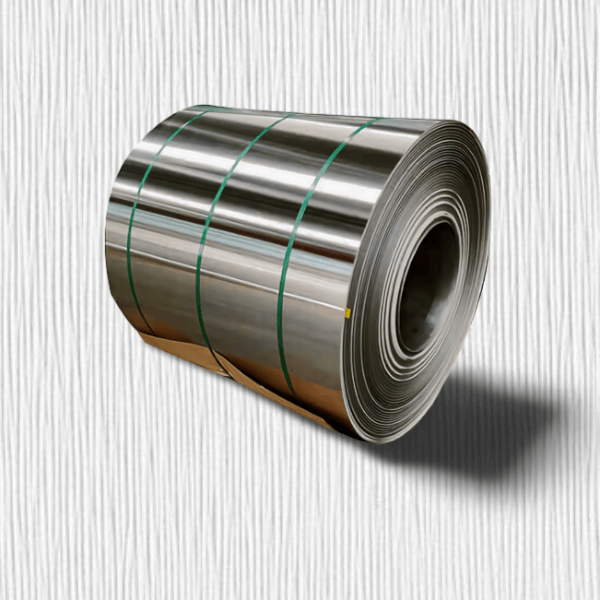

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Alloy 28 Plate

-

ASTM B463 Alloy 28 2B Finish US $20 - $25 / Kg

-

ASME SB463 Alloy 28 Coil US $23 - $24 / Kg

-

UNS N08028 Circle US $22 - $23 / Kg

-

DIN 1.4563 Clad Plate US $24 - $25 / Kg

-

ASTM B463 Alloy 28 CR Sheet US $21 - $22 / Kg

Equivalent Grades Of Alloy 28 Plate

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy 28 | N08028 | 1.4563 |

Chemical Composition Of Alloy 28 Plate

| Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al |

| 30-32 | 22 min | 26-28 | 3-4 | 0.60-1.40 | - | 0.02 max | 2 max | 0.03 max | 0.70 max | - |

Different Types Of Alloy 28 Plate

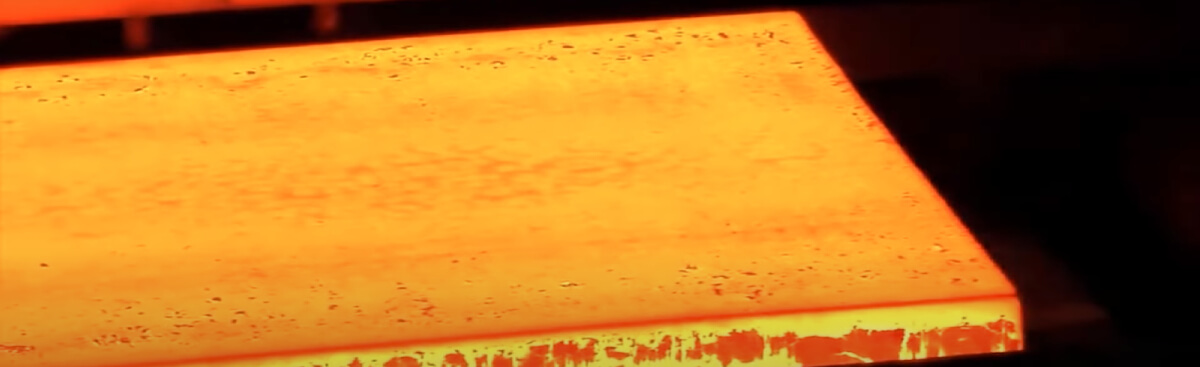

Our Manufacturing Process Of Alloy 28 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Alloy 20 Plate

Our Material

Contact Us

Supplying World Wide