Alloy 254 Flanges

Home » Alloy 254 Flanges

ASTM A182 SMO 254 Flanges Blind Flange, DIN 1.4547 Expander Flange, UNS S31254 Screwed Flange, DIN 1.4547 RTJ Flange, DIN 1.4547 Weldo-Nipo Flange, ASME SA 182 SMO 254 Flanges Slip-On Flange, DIN 1.4547 Forging Facing Flange, DIN 1.4547 Swrf Flange, ASTM A182 SMO 254 Flanges Weld-Neck Flange-A-B.

Alloy 254 Flanges, prominently utilized in components of gas scrubbers in petroleum production and food processing equipment, among other applications, serve as a cost-efficient alternative to high nickel and titanium alloys. These remarkable flanges seamlessly meld with conventional austenitic stainless steels, yielding their wide acceptance in the industry.

Specifically engineered for use in halide-rich environments like marine, hydrochloric acid, and contaminated sulfuric acid, ASTM A182 SMO 254 Flanges Blind Flange present a unique chemical composition with marginally elevated copper content. Aside from this additional element, they resemble most austenitic stainless steels.

The physical properties of these flanges are comparable to specific flange grades, and disparities in drop evaporation tests are considered statistically insignificant, underlining their versatility and efficiency. Renine Metalloys holds a market-leading position as a manufacturer and supplier of SMO 254 RTJ Flanges, providing a vast range of sizes in line with national and international standards. Our flanges are celebrated for their superior chemical properties and characteristics. We’re recognized in the industry for delivering top-flight products, with quality always at the helm of our priorities. We spare no room for errors in our commitment to serve our esteemed global patrons. Our catalogue extends to high, low, and medium flanges, offering exceptional strength and durability.

Our UNS S31254 Screwed Flange have excellent performance, robust construction, superlative corrosion resistance, and minimal maintenance needs. Custom sizes and specifications are also available at competitive prices, tailored to our valuable clients’ prerequisites. Our seasoned professionals meticulously fabricate each flange using premier raw material, adhering strictly to international material standards.

ASME SA 182 SMO 254 Flanges Slip-On Flanges are manufactured employing cutting-edge techniques and sophisticated tools, ensuring the production of dimensionally accurate and durable flanges. The fabrication process unfolds under the vigilant guidance of our expert team, boasting numerous years of experience and proficiency in development. Our packaging, leveraging standard materials, protects the flanges from damage and rust during transit. Customized packaging solutions are also available per the client’s preference for safeguarded delivery. We utilize safe and fast modes of transportation to ensure the timely delivery of orders to our esteemed global clientele.

Specification Of Alloy 254 Flanges

| Specifications | ASTM A182 / ASME SA182 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Alloy 254 Flanges

-

DIN 1.4547 Expander Flange US $3 – $8 / Kg

-

UNS S31254 Nuts-Bolts Flange US $4 – $9 / Kg

-

ASME SA 182 SMO 254 Flanges Flat Flange US $2 – $10 / Kg

-

ASTM A182 SMO 254 Flanges Forged Flange US $5 – $10 / Kg

-

DIN 1.4547 Forging Facing Flange US $3 – $10 / Kg

Equivalent Grades Of Alloy 254 Flanges

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy 254 | S31254 | 1.4547 |

Chemical Composition Of Alloy 254 Flanges

| Grade | C | Mn | Si | Cu | S | P | Mo | Ni | Cr |

| SMO 254 | 0.02 | 1 | 0.08 | 0.5-1.0 | 0.01 | 0.03 | 6.0-6.5 | 17.5-18.5 | 19.5-20.5 |

Different Types Of Alloy 254 Flanges

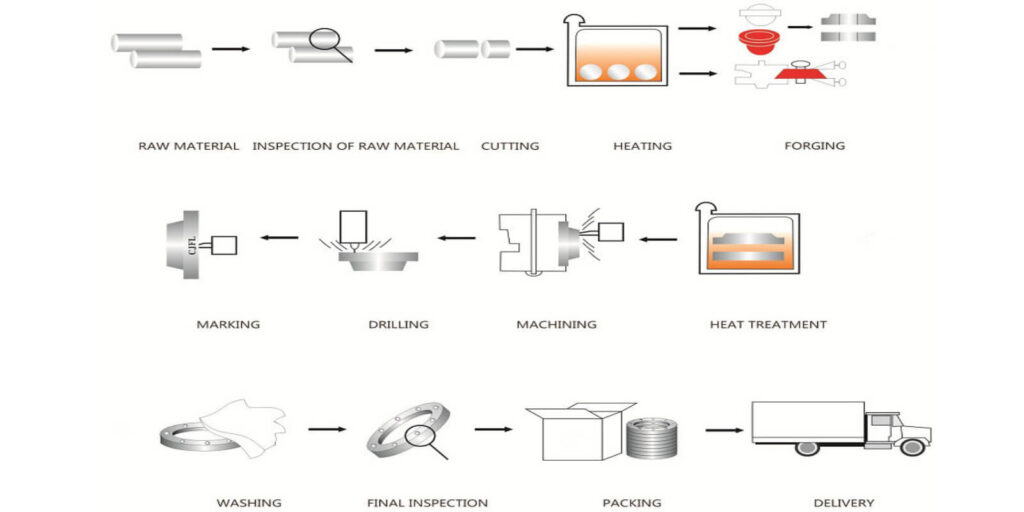

Our Manufacturing Process Of Alloy 254 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Stainless Steel Flanges

Our Material

Contact Us

Supplying World Wide