Alloy 20 Fasteners

Home » Alloy 20 Fasteners

ASTM B473 Alloy 20 Nut, ASME SB473 Alloy 20 Threaded Rod, DIN 2.4660 Hex Nut, UNS N08020 Stud Bolt, UNS N08020 Stud Bolt, UNS N08020 Threaded Rod, ASME SB473 Alloy 20 Bolt, DIN 2.4660 Bolt, ASME SB473 Alloy 20 Fasteners, ASTM B473 Alloy 20 Fasteners.

Alloy 20 is a nickel-based corrosion-resistant and wear-resistant alloy. It is mostly used to fabricate fasteners with a high strength that can withstand extremely severe conditions in the industrial environment. Without these, the equipment would not run efficiently and the machine will be unsafe to use.

ASTM B473 Alloy 20 fasteners secure critical equipment in chemical plants that handle aggressive substances like acids and other harsh chemicals. They’re essential in offshore oil/gas rigs dealing with salty seawater and hydrogen sulfide gas. Pharmaceutical and food factories use them to avoid contamination from corroded metal parts. Shipbuilders rely on Alloy 20 for parts constantly exposed to seawater. Any harsh processing conditions where regular metal can’t cut it.

While stainless steel is corrosion-resistant, Alloy 20 outperforms it when exposed to hot chlorides and aggressive chemical media. Carbon steel is cheap but corrodes easily in moist or chemical environments. So Carpenter 20 Fasteners may be pricier upfront but they pay off through their incredible longevity. Many replace carbon/stainless fasteners frequently but Alloy 20 ones just keep going for decades.

Such fasteners are highly resistant to attack by acids, alkalis, and chlorides which makes them superior to standard stainless steel. Their structures indeed are strong enough to handle high stress and heavy loads without deforming. This alloy maintains its strength over a wide temperature range from cryogenic to excessive hot conditions. Due to their exceptional hardness, the Alloy 20 Bolts can withstand the severity of hostile surroundings for decades.

Alloy 20 fasteners have the advantages of superior corrosion resistance and mechanical strength standing up against extreme temperature and chemical exposures. Their ruggedness and dependability make them indispensable when it comes to operating equipment in tough industries like chemical, oil/gas, pharmaceutical and marine applications.

Renine Metalloys LLP is a trustworthy Alloy 20 supplier & Manufacturer of all Alloy products. Contact us for more details on the Alloy 20 fasterners price.

Specification Of Alloy 20 Fasteners

| Specification | ASTM B473 / ASME SB473 |

| Dimensional specification | ASTM, ASME and API |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

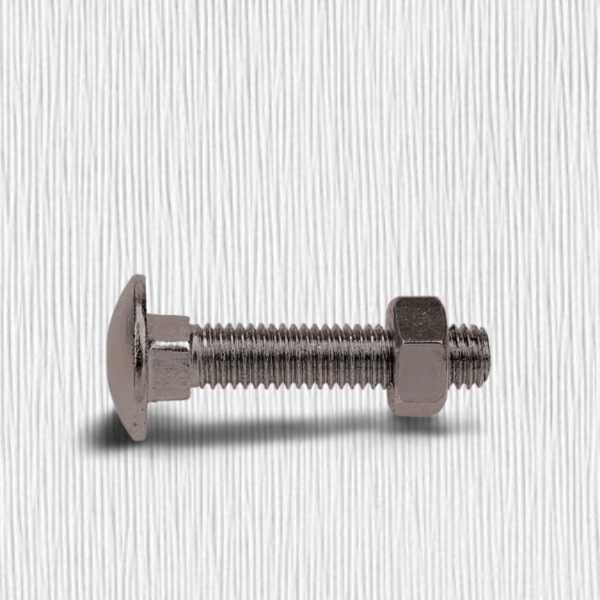

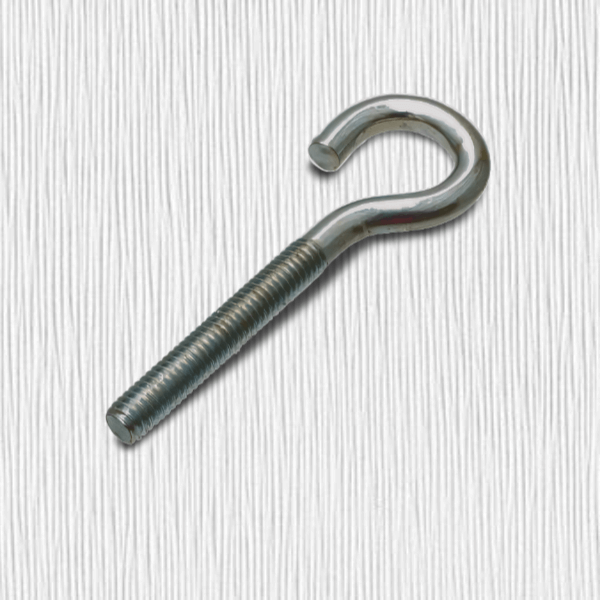

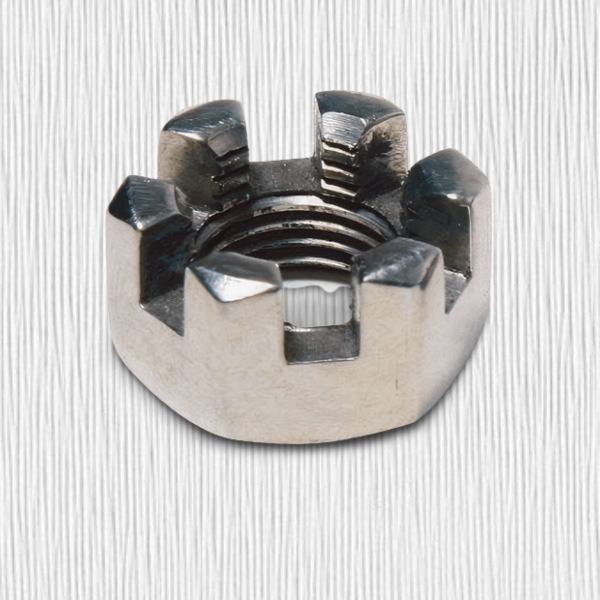

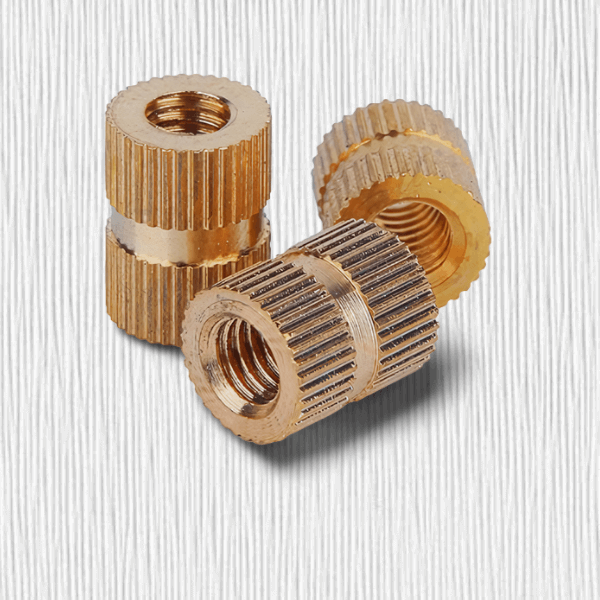

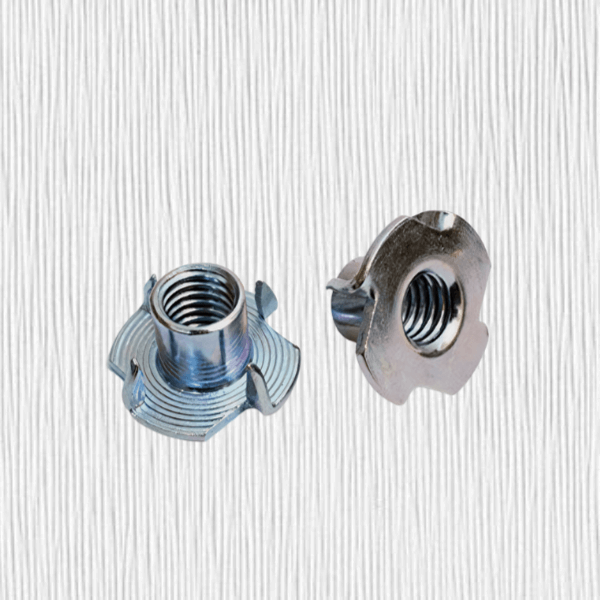

| Form | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Alloy 20 Fasteners

-

ASTM B473 Alloy 20 Washer US $20 - $25 / Kg

-

ASME SB473 Alloy 20 Bolt US $23 - $24 / Kg

-

UNS N08020 Screw US $22 - $23 / Kg

-

DIN 2.4660 Nut US $24 - $25 / Kg

-

ASTM B473 Alloy 20 Fasteners US $21 - $22 / Kg

Equivalent Grades Of Alloy 20 Fasteners

| STANDARD | WERKSTOFF NR. | UNS | EN | AFNOR |

| Alloy 20 | 2.4660 | N08020 | NiCr20CuMo | Z2NCUD31-20AZ |

Chemical Composition Of Alloy 20 Fasteners

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

Mechanical Properties Of Alloy 20 Fasteners

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi – 35,000, MPa – 241 | 30 % |

Different Types Of Alloy 20 Fasteners

Our Manufacturing Process Of Alloy 20 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Alloy Fasteners

Our Material

Contact Us

Supplying World Wide