Inconel 718 Forged Fitting

Home » Inconel 718 Forged Fitting

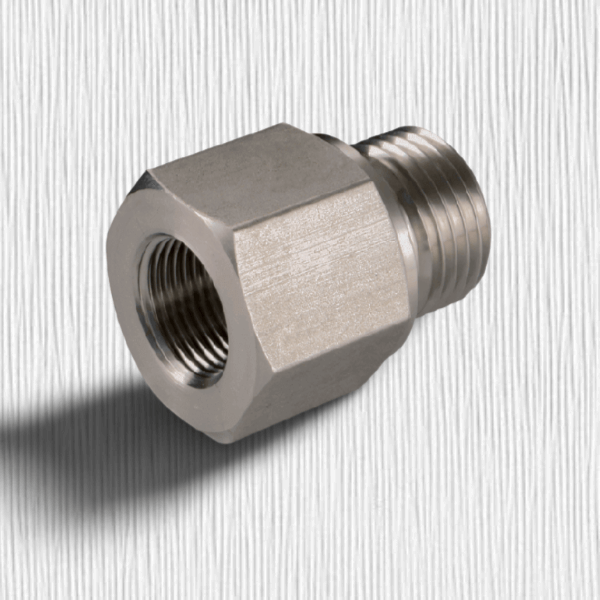

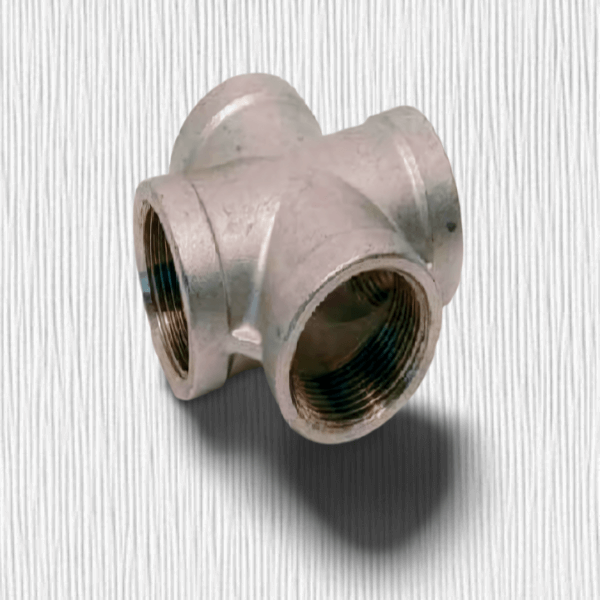

UNS N07718 Forged Adapter Fitting, DIN 2.4668 Forged Full Coupling, ASTM B564 Inconel 718 Forged Cap, DIN 2.4668 Forged Sockolet Fitting, ASTM B564 Inconel 718 Forged Tee, ASTM B564 Inconel 718 Forged Threaded Pipe Nipples, UNS N07718 Forged Half Coupling, UNS N07718 Forged Hex Plug, ASME SB564 Inconel 718 Forged Threaded Reducing Tee, DIN 2.4668 Forged Threaded Lateral Tee.

Inconel 718 forged fittings are well known for their strength, at high temperatures and their adaptability to withstand challenging environments. Made primarily of nickel, chromium and molybdenum ASTM B564 Inconel 718 Forged Cap is an alloy known for its mechanical properties making it a top choice for situations where withstanding heat and lasting durability are important. Crafted through a manufacturing process UNS N07718 Forged Tee showcase grain structure and strength ensuring dependable performance in tough conditions. The forging method enhances the traits of the fittings providing resistance to deformation from prolonged stress and fatigue crucial qualities in applications requiring high temperatures.

A significant benefit of Inconel 718 forged fittings is their ability to retain properties even at high temperatures reaching up to approximately 1300°F (704°C). This outstanding heat endurance makes them suitable for use in aerospace technology, gas turbine engines, nuclear facilities and other industries where extreme temperature changes are frequent. Aside from their heat endurance qualities Inconel 718 forged fittings also demonstrate resistance to corrosion. This feature makes them ideal, for environments exposed to chemicals, acids and oxidation. Their superior corrosion resistance ensures a prolonged lifespan and reduced maintenance expenses contributing to the value of these fittings. Inconel 718 forged fittings are known for their versatility making them easy to integrate into piping systems due, to their weldability. They work well with welding processes, which helps streamline installation and minimize downtime in industrial settings.

These fittings are favored for their ability to withstand temperatures resist corrosion and be easily welded making them ideal for applications requiring reliability and top performance in conditions. Their strong build and outstanding properties make them trusted components, in industries prioritizing durability and safety.

Specification Of Inconel 718 Forged Fitting

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Dimensions | ASME 16.11, MSS SP-79,83,95,97,BS 3799 |

| Size | 1/2"NB TO 4"NB IN |

| Class / Pressure | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | SOCKET WELD (S/W) & SCREWED (SCRD), Threaded – NPT, BSP, BSPT |

Price List Of Inconel 718 Forged Fitting

-

ASTM B564 Inconel 718 Forged Cap US $44 - $50 / Kg

-

ASME SB564 Inconel 718 Forged Cross US $46 - $47 / Kg

-

UNS N07718 Forged Adapter Fitting US $44 - $46 / Kg

-

DIN 2.4668 Forged Full Coupling US $47 - $50 / Kg

-

ASTM B564 Inconel 718 Forged Tee US $45 - $49 / Kg

Equivalent Grades Of Inconel 718 Forged Fitting

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

Chemical Composition Of Inconel 718 Forged Fitting

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | - | 50.00 - 55.00 | 17.00 - 21.00 |

Mechanical Properties Of Inconel 718 Forged Fitting

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Different Types Of Inconel 718 Forged Fitting

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Forged Fitting

Our Material

Contact Us

Supplying World Wide