Inconel 625 Forged Fitting

Home » Inconel 625 Forged Fitting

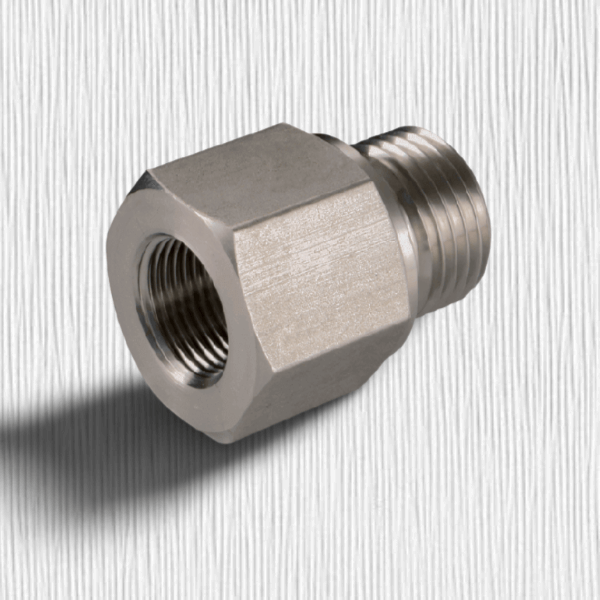

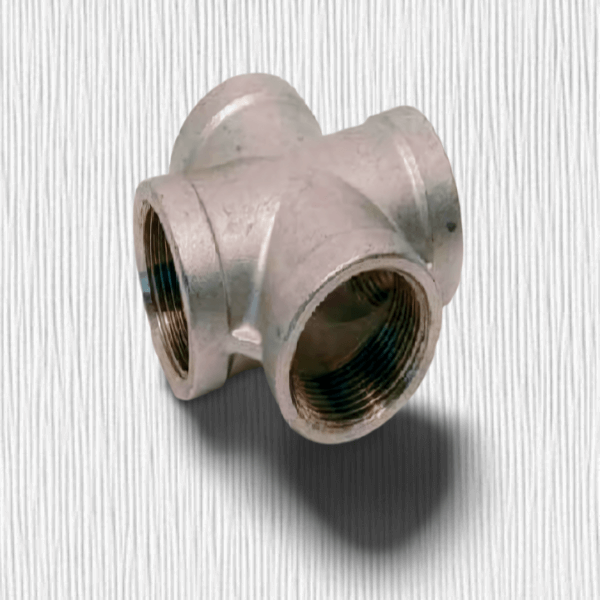

ASME SB564 Inconel 625 Forged 90 Degree Elbow, ASTM B564 Inconel 625 Forged Threaded Plug, ASME SB564 Inconel 625 Forged Union, DIN 2.4856 Forged Full Coupling, DIN 2.4856 Forged Threaded Lateral Tee, ASTM B564 Inconel 625 Forged Tee, ASTM B564 Inconel 625 Forged Threaded Pipe Nipples.

Inconel 625 forged fittings are highly esteemed, in settings for their qualities and durability. Renowned for its nature and outstanding resistance to corrosion UNS N06625 Forged Adapter Fitting is a nickel chromium molybdenum alloy that delivers top notch performance in surroundings.Crafted through a forging technique Inconel 625 forged fittings display grain flow and mechanical features ensuring strength compared to traditional cast fittings. This increased strength makes them perfect for applications requiring pressure and temperature commonly seen in sectors like oil and gas chemical processing, aerospace and marine engineering. A notable aspect of DIN 2.4856 Forged Cap is their ability to resist types of environments including oxidizing and reducing conditions.

They can endure chemicals, acids and seawater making them the preferred choice for applications where corrosion resistance is crucial. The excellent weldability of Inconel 625 forged fittings enhances their adaptability in fabrication processes facilitating installation and upkeep. Their capability to retain their properties at elevated temperatures further enhances their attractiveness in challenging working conditions.

Inconel 625 forged fittings come in forms such as elbows, tees, couplings, unions among others meeting piping needs, in industrial environments.The fittings are usually Produced to adhere norms, like ASTM, ASME and ANSI guaranteeing top notch quality and dependability. Inconel 625 forged fittings are highly regarded for their top tier strength, resistance to corrosion and reliability. With their build and exceptional performance features they play a role, in vital industrial operations where safety and effectiveness are key.

Specification Of Inconel 625 Forged Fitting

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Dimensions | ASME 16.11, MSS SP-79,83,95,97,BS 3799 |

| Size | 1/2"NB TO 4"NB IN |

| Class / Pressure | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | SOCKET WELD (S/W) & SCREWED (SCRD), Threaded – NPT, BSP, BSPT |

Price List Of Inconel 625 Forged Fitting

-

ASTM B564 Inconel 625 Forged Cap US $44 - $50 / Kg

-

ASME SB564 Inconel 625 Forged Cross US $46 - $47 / Kg

-

UNS N06625 Forged Adapter Fitting US $44 - $46 / Kg

-

DIN 2.4856 Forged Full Coupling US $47 - $50 / Kg

-

ASTM B564 Inconel 625 Forged Tee US $45 - $49 / Kg

Equivalent Grades Of Inconel 625 Forged Fitting

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN | OR |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NC22DNB4M | NA 21 | ХН75МБТЮ | NiCr22Mo9Nb | ЭИ602 |

Chemical Composition Of Inconel 625 Forged Fitting

| Ni | Fe | C | Mn | Si | Cr2 | Mo | Co | Al | Ti | Nb + Ta | P | S |

| 58.0 min | 5.0 max | 0.10 max | 0.50 max | 0.50 max | 20.0-23.0 | 8.0-10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15–4.15 | 0.015 max | 0.015 max |

Mechanical Properties Of Inconel 625 Forged Fitting

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi - 1,35,000 , MPa -930 | Psi - 75,000 , MPa - 517 | 42.5 % |

Different Types Of Inconel 625 Forged Fitting

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Forged Fitting

Our Material

Contact Us

Supplying World Wide