Inconel 600 Forged Fitting

Home » Inconel 600 Forged Fitting

ASME SB564 Inconel 600 Forged 90 Degree Elbow, UNS N06600 Forged Threaded Lateral Outlet, ASTM B564 Inconel 600 Forged Tee, ASME SB564 Inconel 600 Forged Threaded Reducing Tee, ASME SB564 Inconel 600 Forged Union, UNS N06600 Forged Hex Plug.

Inconel 600 a blend of nickel and chromium is a material known for its strength and ability to withstand high temperatures and corrosion. When shaped into fittings this material plays a role, in industries facing conditions. ASTM B564 Inconel 600 Socket Weld Reducing Tees offer a choice for applications that demand performance in challenging environments.

These fittings are specially crafted to endure the temperatures in fields like chemical processing, aerospace technology and power generation. At temperatures surpassing 2000°F (1093°C) the material maintains its properties making it well suited for demanding thermal conditions.

Inconel 600 demonstrates resistance against corrosion, including both oxidizing and reducing environments. This resistance prolongs the lifespan of forged fittings ensuring lasting reliability in surroundings where corrosion is a worry.

The forging process enhances the materials strength resulting in fittings withstanding pressure and stress. Inconel 600 Screwed & Threaded Pipe Caps offer toughness and durability minimizing the chances of breakdowns and improving overall system performance.

Whether utilized in petrochemical installations, settings or nuclear plants UNS N06600 FORGED FITTINGS present a solution for an array of industries. Their ability to adapt to applications underscores their significance in operations.

Inconel 600 Forged fittings are crucial, in the oil refining, gas processing and offshore drilling sectors in environments with fluids and high temperatures. They are frequently employed in chemical plants for their durability against substances and their capability to withstand chemical procedures. Inconel 2.4816 Threaded Fittings are parts of power plants providing functionality in hot settings, like boilers, heat exchangers and steam systems.

Specification Of Inconel 600 Forged Fitting

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Dimensions | ASME 16.11, MSS SP-79,83,95,97,BS 3799 |

| Size | 1/2"NB TO 4"NB IN |

| Class / Pressure | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | SOCKET WELD (S/W) & SCREWED (SCRD), Threaded – NPT, BSP, BSPT |

Price List Of Inconel 600 Forged Fitting

-

ASTM B564 Inconel 600 Forged Cap US $44 - $50 / Kg

-

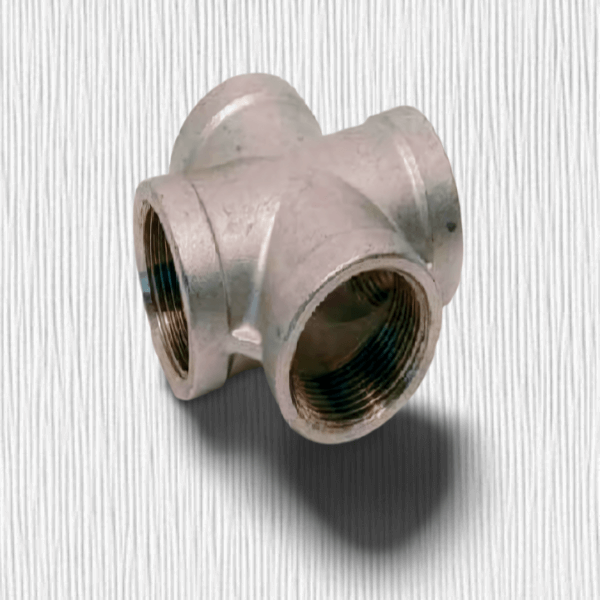

ASME SB564 Inconel 600 Forged Cross US $46 - $47 / Kg

-

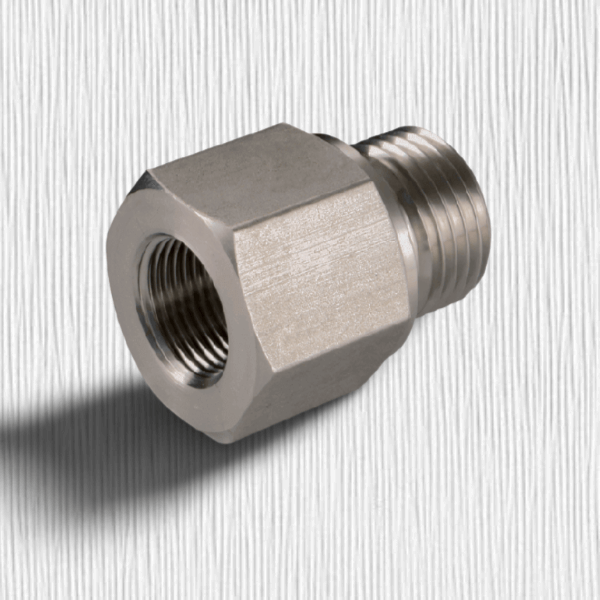

UNS N06600 Forged Adapter Fitting US $44 - $46 / Kg

-

DIN 2.4816 Forged Full Coupling US $47 - $50 / Kg

-

ASTM B564 Inconel 600 Forged Tee US $45 - $49 / Kg

Equivalent Grades Of Inconel 600 Forged Fitting

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | NiCr15Fe | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 |

Chemical Composition Of Inconel 600 Forged Fitting

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015 max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Mechanical Properties Of Inconel 600 Forged Fitting

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Different Types Of Inconel 600 Forged Fitting

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Forged Fitting

Our Material

Contact Us

Supplying World Wide