Alloy 254 Fasteners

Home » Alloy 254 Fasteners

DIN 1.4547 Threaded Rod, SMO 254 Threaded Rod, SMO 6moly Bolt, DIN 1.4547 Bolt, SMO 254 Stud Bolt, SMO 6moly Hex Nut, SMO 254 Stud Bolt, UNS S31254 Nut, UNS S31254 Nut, SMO 6moly Hex Nut, UNS S31254 Fasteners, DIN 1.4547 Fasteners.

Alloy 254 is a nickel-based alloy containing chromium, molybdenum, and other elements. Its unique composition gives it some excellent properties.

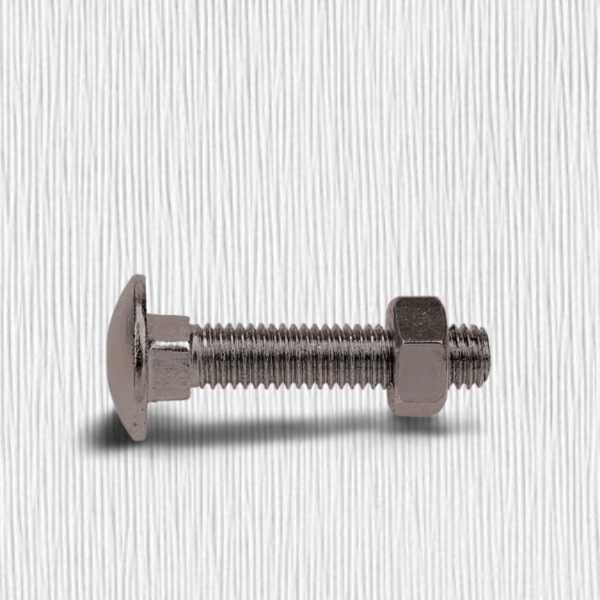

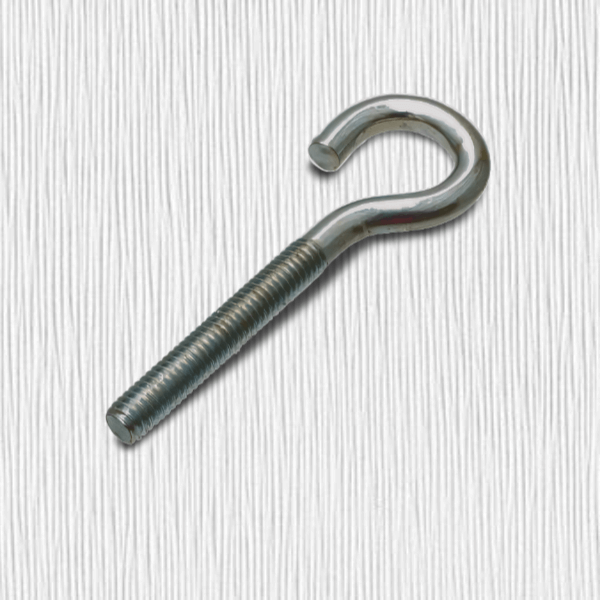

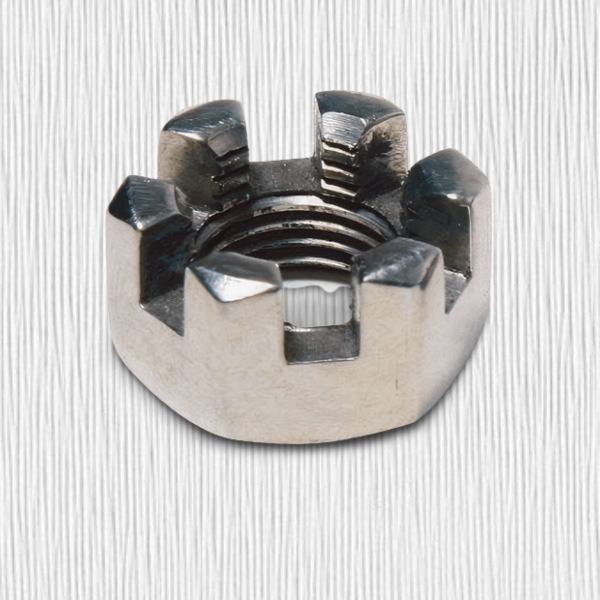

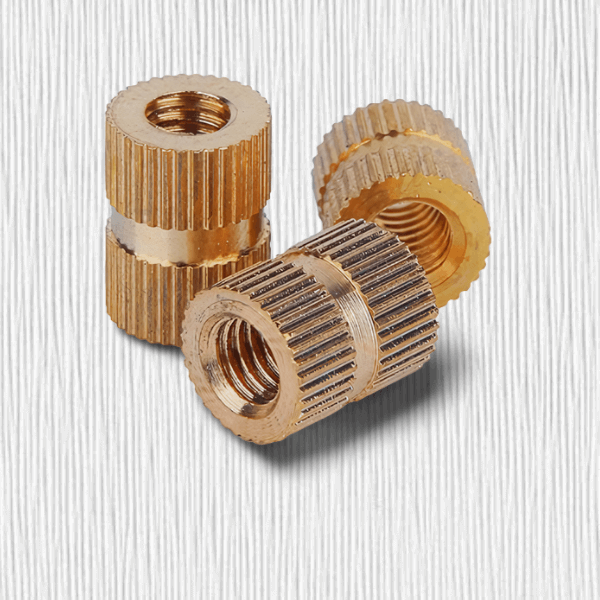

SMO 6moly Hex Nut comes with all the fastener types – bolts, nuts, screws, washers, and studs. Manufacturers also make speciality fasteners from this superalloy. Products like U-bolts, huck bolts, and Eye-bolts. This fastener needed for a brutal environment can be made from corrosion-busting Alloy 254. The fastener options are almost endless.

Industries dealing with high heat, extreme cold, caustic chemicals or salty air rely heavily on UNS S31254 Fasteners. The important ones are oil/gas extraction and processing, chemical plants, marine construction, and power generation facilities.

These fasteners get used everywhere from offshore rigs to desalination plants to wastewater treatment systems. They can handle it all – high pressures, temperatures, acidity and more. Any harsh industrial environment is prime territory for SMO 254 Stud Bolt.

The biggest perk of these Fasteners is their good corrosion resistance. They won’t crack, rust, or degrade from chemical exposure. These are the best metal when you need exceptional strength and durability from the alloy. Despite being lighter than steel, it’s deceptively sturdy. These DIN 1.4547 Fasteners can handle intense mechanical stresses. And they’ll keep performing awesomely for 30, 40, 50+ years in horrendous conditions.

Alloy 254 is one remarkable metal with corrosion-fighting prowess and brawn to boot. Its fasteners shine in harsh industrial environments like chemical processing, offshore operations, and power plants.

Renine Metalloys LLP is a trustworthy SMO 254 Fastener Supplier & Manufacturer of all kinds of Alloy products. Contact us for more details on the Alloy 254 material, specification and price list.

Specification Of Alloy 254 Fasteners

| Specification | ASTM F594, A194 / ASME SF594, SA194 |

| Dimensional specification | ASTM, ASME and API |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

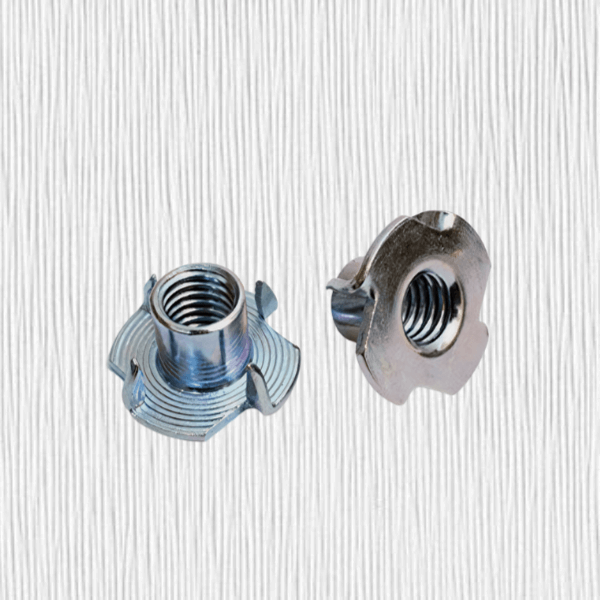

| Form | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Alloy 254 Fasteners

-

UNS S31254 Washer US $3 – $8 / Kg

-

DIN 1.4547 Bolt US $4 – $9 / Kg

-

SMO 254 Screw US $2 – $10 / Kg

-

SMO 6moly Nut US $5 – $10 / Kg

-

UNS S31254 Fasteners US $3 – $10 / Kg

Equivalent Grades Of Alloy 254 Fasteners

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy 254 | S31254 | 1.4547 |

Chemical Composition Of Alloy 254 Fasteners

| Grade | C | Mn | Si | Cu | S | P | Mo | Ni | Cr |

| SMO 254 | 0.02 | 1 | 0.08 | 0.5-1.0 | 0.01 | 0.03 | 6.0-6.5 | 17.5-18.5 | 19.5-20.5 |

Mechanical Properties Of Alloy 254 Fasteners

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Different Types Of Alloy 254 Fasteners

Our Manufacturing Process Of Alloy 254 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

SMO Fasteners

Our Material

Contact Us

Supplying World Wide