Alloy 254 Plate

Home » Alloy 254 Plate

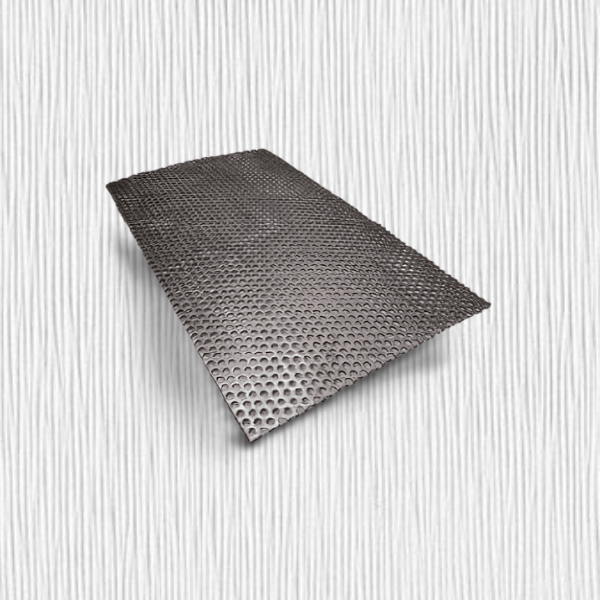

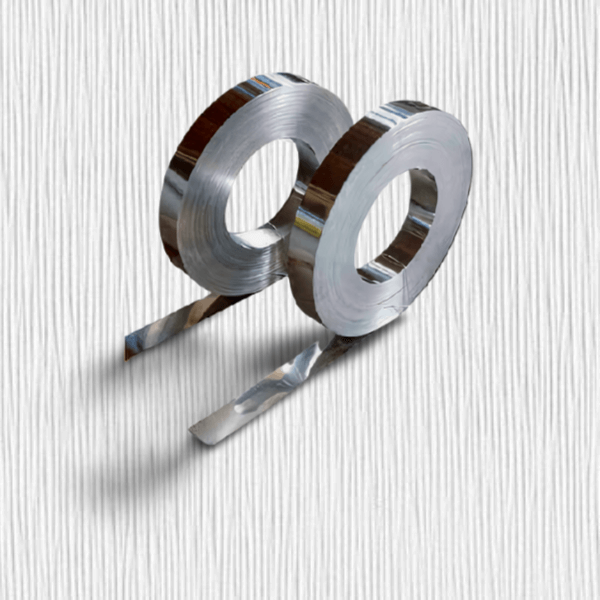

UNS S31254 Ring, ASME SA479 Alloy 254 Rolls, ASME SA240 Alloy 254 Coil, ASTM A240 Alloy 254 Sheets, ASME SA240 Alloy 254 Flats, UNS S31254 Circle, ASTM A240 Alloy 254 2B Finish, ASTM A240 Alloy 254 Perforated Sheets, UNS S31254 Plain Sheet.

Alloy 254 Plate is a special metal plate made from a mix of metals including nickel, chromium, molybdenum, and iron. About one-quarter of Alloy 254 is chromium. Chromium helps the plates stand up to corrosion. Corrosion happens when chemicals attack and damage metals. The chromium in ASTM A240 Alloy 254 Perforated Sheets makes them equal to more expensive plates at resisting corrosion. This makes Alloy 254 a good economical choice for chemicals and heat equipment.

The plates also nickel and molybdenum. These add to the excellent heat resistance of Alloy 254. The plates keep their strength and structure even when exposed to very high temperatures up to 1150°F for a long time.

They can handle extreme heating and cooling cycles well too. This thermal stability makes the alloy great for applications that get very hot like chemical plants, oil refineries, and factories, On top of resisting corrosion and heat, Alloy 254 is also easy to shape and work with. The plates can be welded and formed using typical methods. They have good impact resistance for metal plates. And they machine well also – tools can cut the plates to precise shapes. This versatility expands the types of projects the alloy can be used for.

The austenitic structure of the UNS S31254 Plain Sheet provides good ductility and toughness alongside high strength. Its typical tensile strength is around 160 megapascals at room temperature. Strength is retained fairly well as temperatures go up. For example, at 700 degrees Celsius, the tensile strength remains over 130 megapascals. This allows Alloy 254 to withstand substantial mechanical loads through a wide temperature range.

ASTM A240 Alloy 254 Sheets stands up to heat, corrosion, thermal cycles and mechanical stress far better than typical metal plates. It resists high temperatures and damaging chemicals. But it still machines and fabricates well. The durability and ease of use gets the plates onto equipment in extremely hot, tough industrial environments.

Renine Metalloys LLP is a trustworthy 254 SMO Plate supplier & Manufacturer of all Alloy products. Contact us for more details on the Alloy 254 price per kg

Specification Of Alloy 254 Plate

| Specification | ASTM A240 / ASME SA240 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

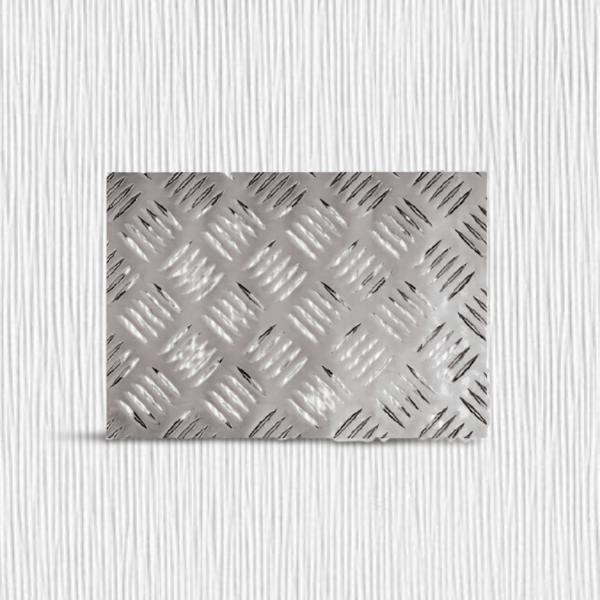

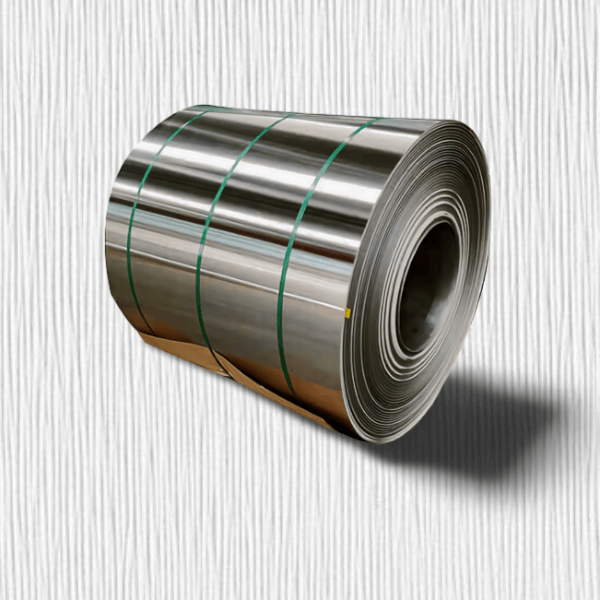

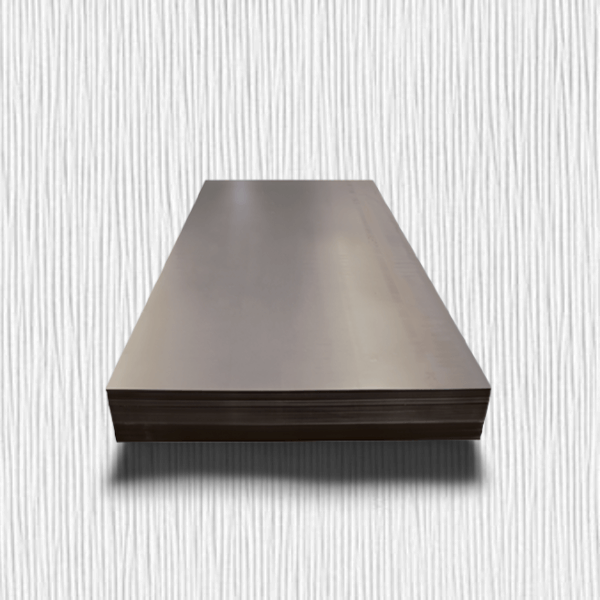

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Alloy 254 Plate

-

ASTM A240 Alloy 254 2B Finish US $3 – $8 / Kg

-

ASME SA240 Alloy 254 Coil US $4 – $9 / Kg

-

UNS S31254 Circle US $2 – $10 / Kg

-

DIN 1.4547 Clad Plate US $5 – $10 / Kg

-

ASTM A240 Alloy 254 CR Sheet US $3 – $10 / Kg

Equivalent Grades Of Alloy 254 Plate

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy 254 | S31254 | 1.4547 |

Chemical Composition Of Alloy 254 Plate

| Grade | C | Mn | Si | Cu | S | P | Mo | Ni | Cr |

| SMO 254 | 0.02 | 1 | 0.08 | 0.5-1.0 | 0.01 | 0.03 | 6.0-6.5 | 17.5-18.5 | 19.5-20.5 |

Different Types Of Alloy 254 Plate

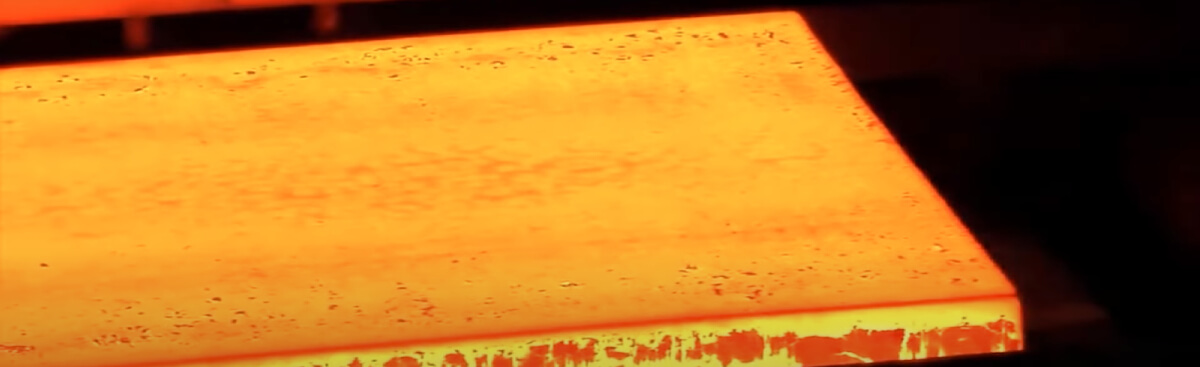

Our Manufacturing Process Of Alloy 254 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Stainless Steel Plate

Our Material

Contact Us

Supplying World Wide