Inconel 625 Fasteners

Home » Inconel 625 Fasteners

Werkstoff Nr 2.4856 Bolt, ASTM B166 Inconel 625 Fasteners, ASME SB166 Inconel 625 Bolt, ASTM B166 Inconel 625 Nut, ASTM B166 Inconel 625 Nut, Werkstoff Nr 2.4856 Fasteners, ASME SB166 Inconel 625 Hex Nut, UNS N06625 Stud Bolt, ASME SB166 Inconel 625 Hex Nut, UNS N06625 Stud Bolt.

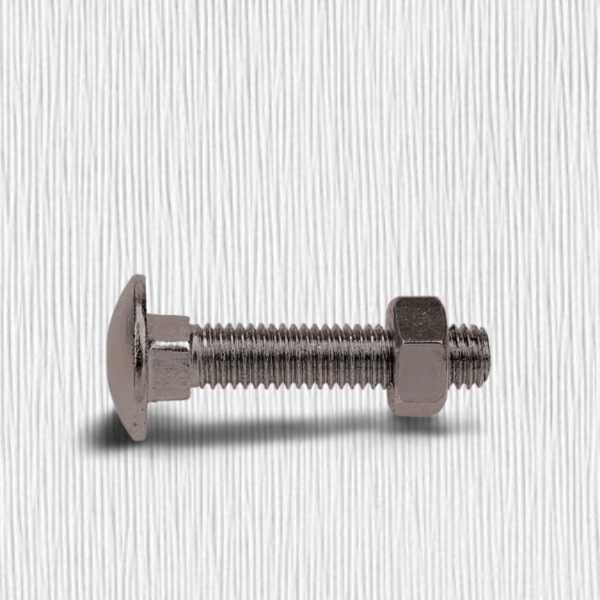

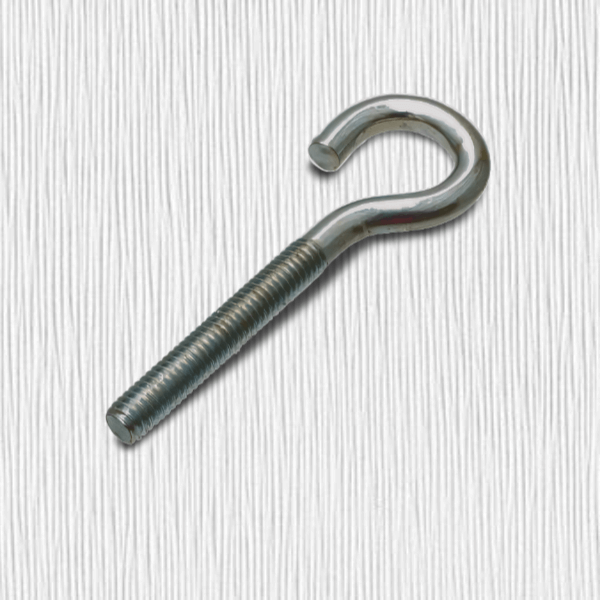

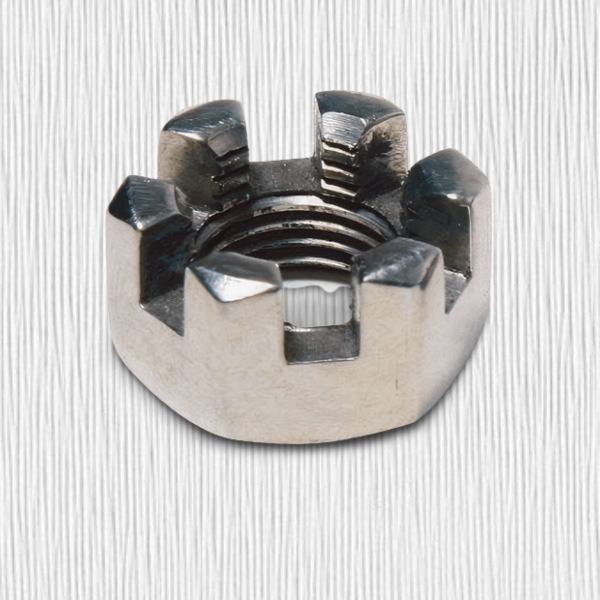

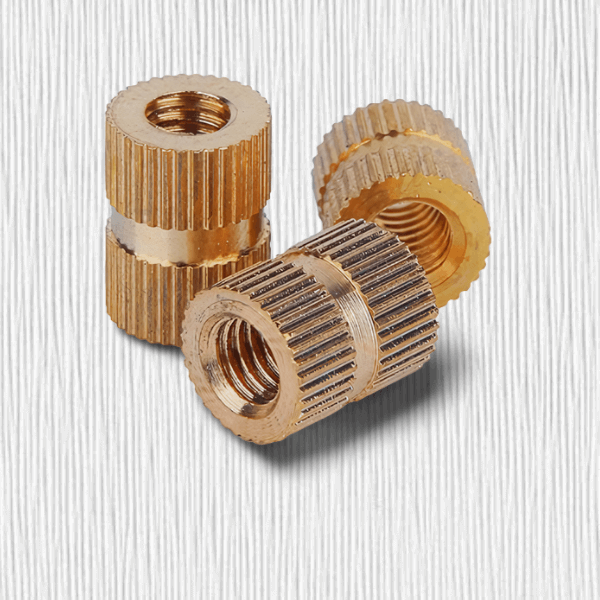

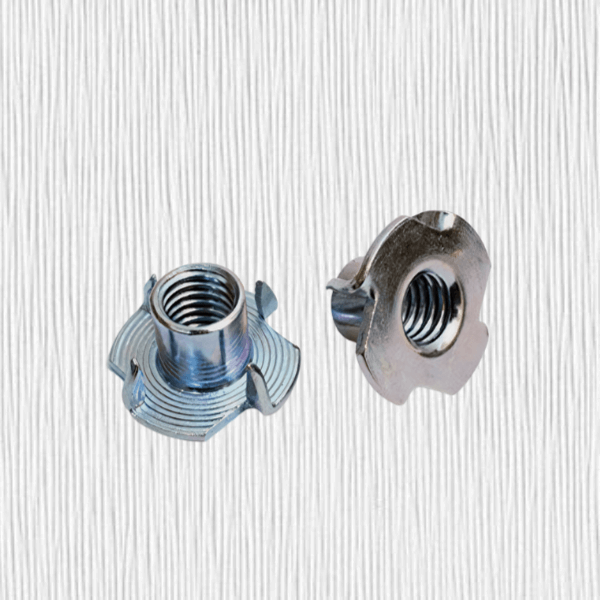

Fasteners are hardware components used to join different parts together securely. Common examples include nuts, bolts, screws, rivets, and more.

Inconel 625 belongs to the Ni-Cr superalloy family that is very often used in bolting applications. It is also characterized by its impressive properties to resist corrosion and high tensile strength. This alloy contains substantial quantities of nickel, chromium and molybdenum in particular. Moreover, there are trace quantities of niobium and other elements coexisting.

The precise composition gives UNS N06625 Stud Bolt several highly desirable characteristics. It displays excellent resistance to oxidation and other forms of corrosion. Additionally, it retains high strength across a wide temperature range. Inconel fasteners perform reliably from cryogenic conditions up to 2000°F.

Such performance makes them indispensable for harsh operating environments. They find extensive use across various industries as a result. Within the chemical processing industry, Werkstoff Nr 2.4856 Bolt enable equipment longevity. They resist damage from potent acids, caustics, and other corrosives.

The energy sector, including oil/gas and power generation, is another major market. These fasteners withstand the extreme temperatures involved. For similar reasons, they are invaluable throughout the aerospace realm. Jet engines, exhaust systems, and spacecraft components all use them.

Other applications include nuclear reactors, pollution control systems, and more. Essentially, any scenario is too severe for conventional steel fasteners. Beyond temperature/corrosion resistance, ASTM B166 Inconel 625 Nut delivers robust mechanical strength. It can bear substantial loads without deforming, cracking, or failing.

This strength holds even after years of thermal/corrosive exposure. Such durability provides a long usable lifespan for these fasteners. While more expensive, the upfront cost justifies itself over time. Inconel fasteners rarely require replacement compared to cheaper, weaker alternatives.

Inconel 625 fasteners provide an invaluable solution. Their unique composition imparts unmatched corrosion resistance and high-temperature strength.

Renine Metalloys LLP is a trustworthy Inconel 625 supplier & Manufacturer of all Inconel products. Contact us for more details on the Inconel 625 price.

Specification Of Inconel 625 Fasteners

| Standard | ASTM B166, ASME SB166 |

| Dimensions | ANSI B18.2.2, DIN 934,ISO 4032, BS1768, BS 1769 |

| Length | 3 mm to 200 mm |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Type | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Inconel 625 Fasteners

-

ASTM B166 Inconel 625 Washer US $44 - $50 / Kg

-

Werkstoff Nr 2.4856 Bolt US $46 - $47 / Kg

-

UNS N06625 Screw US $44 - $46 / Kg

-

ASME SB166 Inconel 625 Nut US $47 - $50 / Kg

-

ASTM B166 Inconel 625 Fasteners US $45 - $49 / Kg

Equivalent Grades Of Inconel 625 Fasteners

| STANDARD | UNS | WNR. |

| Inconel 725 | N06725 | 2.4856 |

Chemical Composition Of Inconel 625 Fasteners

| Ni | Fe | C | Mn | Si | Cr2 | Mo | Co | Al | Ti | Nb + Ta | P | S |

| 58.0 min | 5.0 max | 0.10 max | 0.50 max | 0.50 max | 20.0-23.0 | 8.0-10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15–4.15 | 0.015 max | 0.015 max |

Mechanical Properties Of Inconel 625 Fasteners

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi - 1,35,000 , MPa -930 | Psi - 75,000 , MPa - 517 | 42.5 % |

Different Types Of Inconel 625 Fasteners

Our Manufacturing Process Of Inconel 625 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Fasteners

Our Material

Contact Us

Supplying World Wide