Inconel 602CA Plate

Home » Inconel 602CA Plate

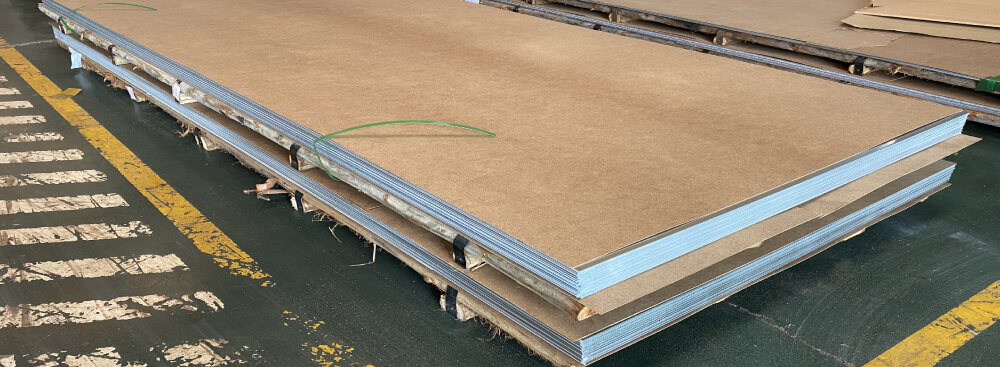

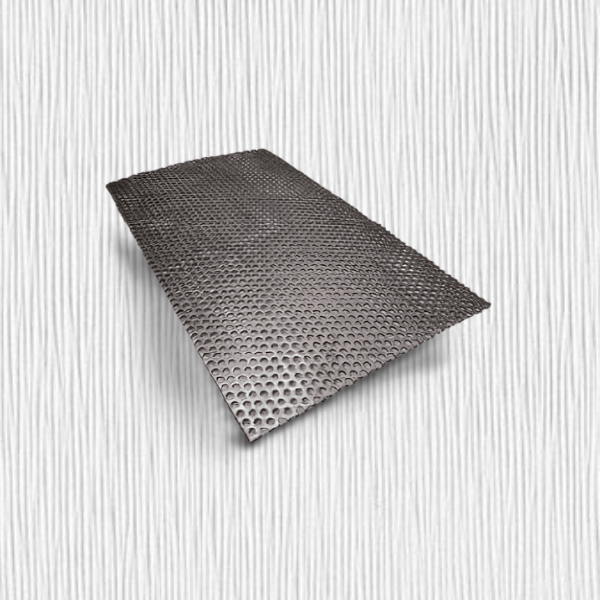

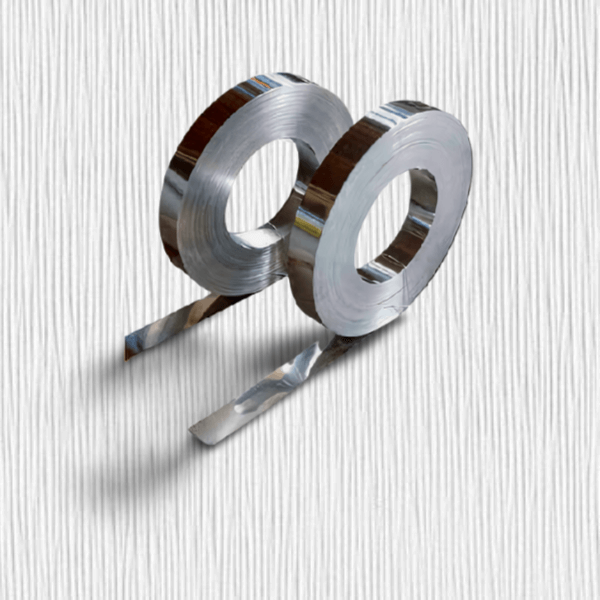

ASME SB168 Inconel 602CA Flats, ASTM B168 Inconel 602CA 2B Finish, ASTM B168 Inconel 602CA CR Sheet, ASTM B168 Inconel 602CA Perforated Sheets, UNS N06025 Ring, UNS N06025 Foil Sheet, UNS N06025 Circle.

Inconel 602CA is a nickel and chromium alloy plate that has high strength and good resistance to corrosion. This metal contains large amounts of chromium and aluminium plus small quantities of carbon, manganese, silicon, sulphur and iron. The chromium gives it good protection against oxidation and corrosion. The aluminium improves the mechanical properties and makes it easier to fabricate.

The ASTM B168 Inconel 602CA Shims has several excellent qualities that make it useful where high-temperature strength and corrosion resistance are needed. It keeps its strength and stability even when exposed to very high temperatures. The plate can be welded and formed easily, which allows it to be made into different shapes and parts. It is stronger than many stainless steels but still resists corrosion very well.

It has high-temperature strength. It can handle temperatures up to 2200°F while keeping good structural stability and strength. This makes it suitable for parts and components exposed to very high heat.

It has oxidation resistance. It forms a protective chromium oxide layer on the surface that protects the underlying metal from more corrosion and oxidation. This gives excellent high-temperature corrosion resistance.

It has good corrosion resistance. It resists corrosion from acids, alkalis, salts, and other harsh environments. It provides good protection in chemical processing applications.

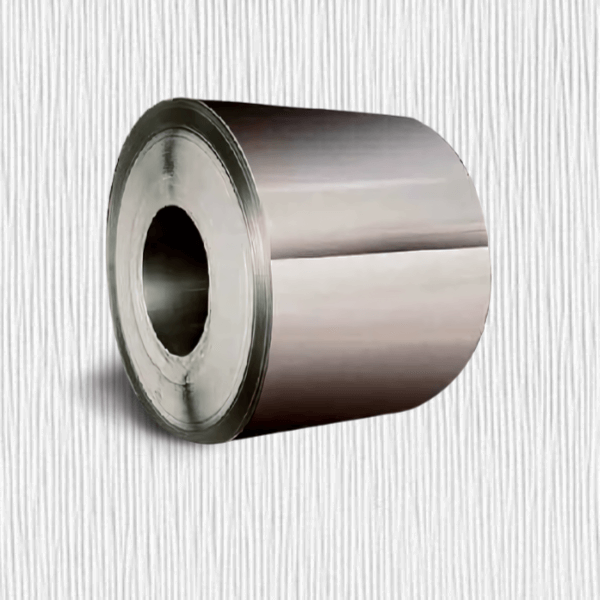

The combination of properties makes ASTM B168 Inconel 602CA Coil useful for many high-temperature applications where corrosion resistance is also needed. For petrochemical plants, power generation equipment and other systems with hot, corrosive environments. It provides a long service life. The high-temperature strength allows it to be used for combustion chambers and other hot sections. Oxidation resistance helps, too.

Inconel 602CA gives an excellent mix of high-temperature strength, weldability, and corrosion resistance. This makes it a flexible material for demanding applications in extreme conditions. With proper maintenance, parts made from Inconel 602CA plates can provide a long and reliable service life.

Specification Of Inconel 602CA Plate

| Specifications | ASTM B168 / ASME SB168 |

| Dimensional specification | ASTM, ASME and API |

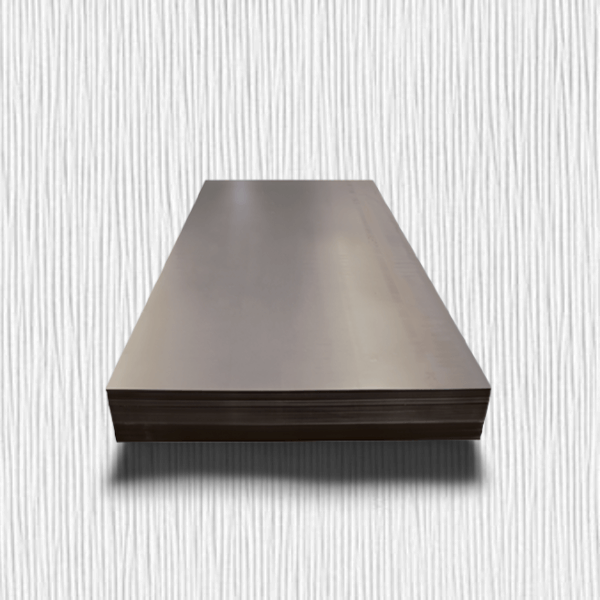

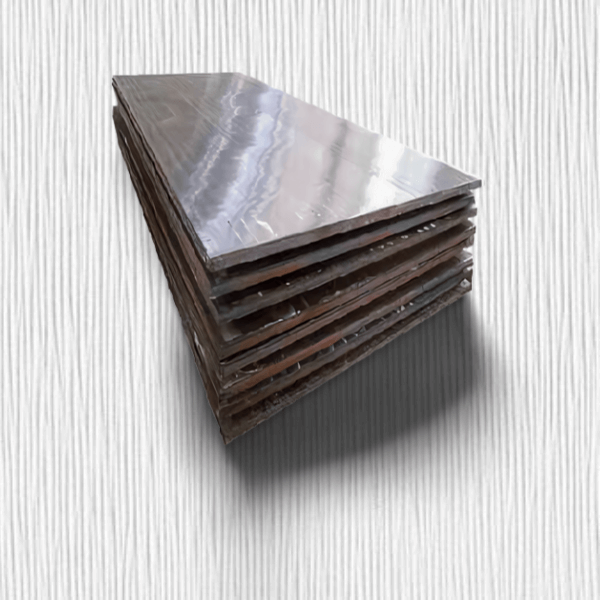

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

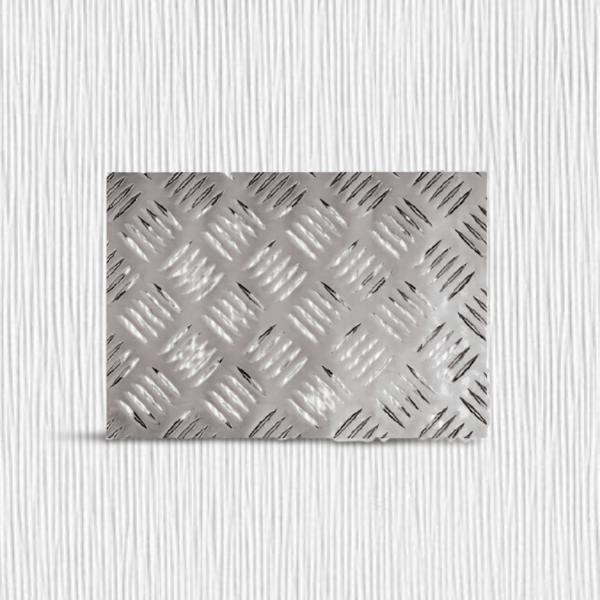

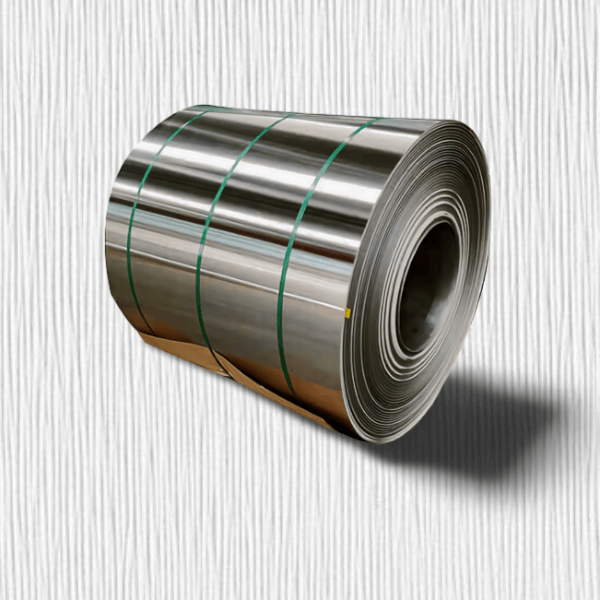

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of Inconel 602CA Plate

-

DIN 2.4633 Clad Plate US $47 - $50 / Kg

-

ASTM B168 Inconel 602CA 2B Finish US $44 - $50 / Kg

-

UNS N06025 Circle US $44 - $46 / Kg

-

ASTM B168 Inconel 602CA CR Sheet US $45 - $49 / Kg

-

ASME SB168 Inconel 602CA Coil US $46 - $47 / Kg

Equivalent Grades Of Inconel 602CA Plate

| STANDARD | UNS | WNR. |

| Inconel 602CA | N06025 | 2.4633 |

Chemical Composition Of Inconel 602CA Plate

| Alloy | % | Cr | Cu | Ni | P | S | Fe | C | Al | Ti | Y | Zr | Si | Mn |

602CA | Min. | 24.0 | - | balance | - | - | 8.0 | 0.15 | 1.8 | 0.1 | 0.05 | 0.01 | - | - |

Max. | 26.0 | 0.1 | 0.02 | 0.01 | 11.0 | 0.25 | 2.4 | 0.2 | 0.12 | 0.1 | 0.5 | 0.15 |

Mechanical Properties Of Inconel 602CA Plate

| Temperature, ° F | 68 | 1000 | 1500 | 1600 | 1800 | 2000 | 2200 |

| Ultimate Tensile Strength, ksi | 105 | 93.4 | 41.2 | 32.8 | 17.1 | 13 | 5.8 |

| 0.2%Yield Strength, ksi | 50.5 | 38.3 | 34.8 | 28.7 | 15.2 | 11.6 | 5.0 |

| Elongation, % | 38 | 43 | 78 | 82 | 78 | 85 | 96 |

Different Types Of Inconel 602CA Plate

Our Manufacturing Process Of Inconel 602CA Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Plate

Our Material

Contact Us

Supplying World Wide