Super Duplex 32760 Pipe

Home » Super Duplex 32760 Pipe

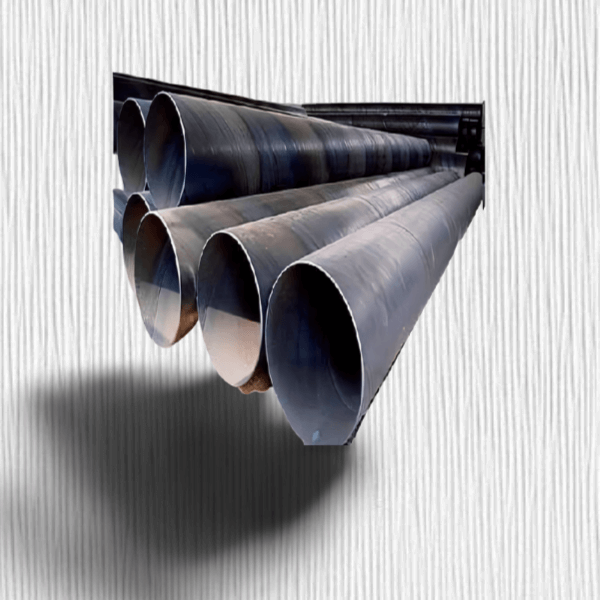

Super Duplex S32760 Seamless Pipes, Super Duplex Steel SAF 2507 Tubes, Super Duplex 1.4410 Pipe, ASTM A790 Super Duplex S32760 Boiler Tube, DIN 1.4501 Triangle Tube, Super Duplex S32760 Tubes, SAF 2507 Pipes, ASTM A790 Super Duplex S32760 ERW Pipe, Duplex Square Tube, UNS S32760 Cold Drawn Tube.

Super Duplex 32760 Pipe Fittings are very useful metals, made specifically for industrial applications that ask for the highest durability. Made from a special nickel-chromium-molybdenum alloy, these fittings have high resistance against corrosion and oxidation.

This super-strength alloy ASTM A790 Super Duplex S32760 ERW Pipe also has mechanical properties. It enables the fittings to withstand high pressures and temperatures. Their toughness and tensile strength surpass ordinary steel which makes them ideal for harsh environments. They maintain high ductility and control deformation without fracturing.

The unique chromium-rich composition forms a passive layer and shields the core metal from aggressive chemicals and media. This barrier ensures long-lasting protection against pitting, crevice corrosion, and stress cracking. The molybdenum further enhances resistance to localized acid attacks.

These versatile fittings excel in industries grappling with highly corrosive conditions, such as chemical processing plants. Here, their imperviousness to acids, alkalis, and solvents allows reliable, leak-free fluid transfer. Their thermal and mechanical resilience ensures safe operation under punishing temperatures and pressures.

Their application extends to offshore oil and gas platforms, where the harsh marine atmosphere would rapidly degrade inferior alloys. The fittings’ immunity to chlorides prevents catastrophic failures from salt spray and seawater exposure. Their strength safeguards piping integrity against powerful ocean currents and storm impacts.

Remarkably low maintenance requirements markedly reduce operational costs over their extensive lifespan. Periodic inspections replace frequent replacement cycles common with conventional materials. This consistency minimizes hazardous leaks and unplanned shutdowns, bolstering productivity and safety simultaneously.

UNS S32760 Cold Drawn Seamless Tube epitomize engineering ingenuity, merging superior metallurgy with manufacturing processes. Their durability and reliability render them indispensable for mission-critical fluid handling across every industry which requires high performance.

Renine Metalloys LLP is a trustworthy Super Duplex 32760 Pipe supplier & Manufacturer of all Super Duplex products. Contact us for more details on the Super Duplex 32760 price per kg

Specification Of Super Duplex 32760 Pipe

| Specifications | ASTM A790 / ASME SA790, ASTM A789 / ASME SA A789 |

| Dimensional specification | ASTM, ASME and API |

| Seamless Pipes & Tubes Sizes | 1 / 2" NB - 8" NB |

| Welded Pipes & Tubes Sizes | 6" NB - 24" NB |

| Outer Diameter | 6.0-630mm |

| Length | Single Random, Double Random & Cut Length |

| Thickness | 0.3mm – 50 mm |

| Type | Seamless / ERW / Welded/ Fabricated |

| Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U" Shape, Pan Cake Coils, Hydraulic Tubes |

Price List Of Super Duplex 32760 Pipe

-

DIN 1.4501 Spiral Pipe US $14 - $18 / Kg

-

ASME SA 790 Super Duplex S32760 Square Pipes US $15 - $17 / Kg

-

ASTM A790 Super Duplex S32760 Round Pipes US $14 - $18 / Kg

-

UNS S32760 Rectangular Pipes US $14 - $18 / Kg

-

DIN 1.4501 Polished Pipes US $14 - $18 / Kg

Equivalent Grades Of Super Duplex 32760 Pipe

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex S32760 | 1.4501 | S32760 |

Chemical Composition Of Super Duplex 32760 Pipe

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Properties Of Super Duplex 32760 Pipe

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000, MPa – 800 | Psi – 80000, MPa – 550 | 15 % |

Different Types Of Super Duplex 32760 Pipe

Our Manufacturing Process Of Super Duplex 32760 Pipe

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Super Duplex Pipe

Our Material

Contact Us

Supplying World Wide