Hastelloy C276 Flanges

Home » Hastelloy C276 Flanges

JIS NW 0276 Weldo-Nipo Flange, UNS N10276 Groove-Tongue Flange, ASTM B564 Hastelloy C276 Square Flange, JIS NW 0276 RTJ Flange, ASTM B564 Hastelloy C276 Socket-Weld Flange, UNS N10276 Wnrf Flange, ASTM B564 Hastelloy C276 Blind Flange, DIN 2.4819 Flat Flange.

Renine Metalloys LLP is a distinguished manufacturer, distributor, and stockist of exceptional Hastelloy C276 Flanges, serving clientele across the globe. We construct these flanges in assorted types, grades, sizes, and dimensions, strictly adhering to national and international quality standards. The universally recognized alloy, DIN 2.4819 Flat Flange, houses integral elements like nickel, chromium, and molybdenum, ideally suited for flange fabrication. An additional tungsten contributes to remarkable corrosion and oxidation resistance under severe conditions.

We take immense pride in crafting superior Hastelloy C276 Flanges, recognized for their exceptional versatility, tensile strength, resilience, and corrosion resistance. Due to their elevated toughness and tensile strength, DIN 2.4819 Lap-Joint Flange stand robust against high-pressure and temperature environments. Their remarkable formability, weldability, workability, and fabricability equip them for service in diverse industries, including petrochemical, pharmaceutical, and paper and pulp sectors.

Renine Metalloys LLP operates from a highly advanced manufacturing facility, harnessing state-of-the-art machinery for creating the UNS N10276 Screwed Flange. Our expansive flange inventory enables timely delivery in alignment with client specifications. Our dedicated workforce strives to create flanges that fulfill our reputable clients’ precise necessities, employing visionary techniques and equipment during fabrication. The Hastelloy C276 Flanges, known for their superior creep-rupture and stress-rupture properties, are provided to the global industrial market at competitive prices. Premium-grade raw material is employed in producing these flanges, ensuring optimal performance and minimal maintenance requirements.

Each manufacturing process transpires under the vigilant supervision of our expert team, guaranteeing that international quality standards are strictly adhered to for efficient flange production. We manufacture the Hastelloy C276 Flanges according to standard and custom-made specifications, catering to the exact needs of our esteemed clients. To ensure maintained quality and performance, our quality control experts perform rigorous quality checks involving a comprehensive set of destructive and non-destructive inspections, wherein various flange attributes are tested. Each flange’s thorough testing is prioritized before dispatching to ensure only defect-free and dimensionally accurate Hastelloy C276 Flanges reach the customer.

Adequate packaging materials are employed in packing these flanges to circumvent any damage during transit. We steadfastly pledge timely flange delivery to specified locations worldwide, underscoring our commitment to quality, service, and customer satisfaction.

Specification Of Hastelloy C276 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Hastelloy C276 Flanges

-

UNS N10276 Screwed Flange US $44 - $50 / Kg

-

DIN 2.4819 Slip-On Flange US $46 - $47 / Kg

-

ASTM B564 Hastelloy C276 Socket-Weld Flange US $44 - $46 / Kg

-

JIS NW 0276 Spades-Rings-Spacer Flanges US $47 - $50 / Kg

-

UNS N10276 Sorf Flange US $45 - $49 / Kg

Equivalent Grades Of Hastelloy C276 Flanges

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | OR | GOST |

| Hastelloy C276 | N10276 | 2.4819 | - | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |

Chemical Composition Of Hastelloy C276 Flanges

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

| Hastelloy C276 | Balance | 0.01 max | 15–17 | 1.0 max | 0.08 max | 4–7 | 0.04 max | 0.03 max | 2.5 max | 14.5–16.5 | 3–4.5 | 0.35 max |

Mechanical Properties Of Hastelloy C276 Flanges

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

Different Types Of Hastelloy C276 Flanges

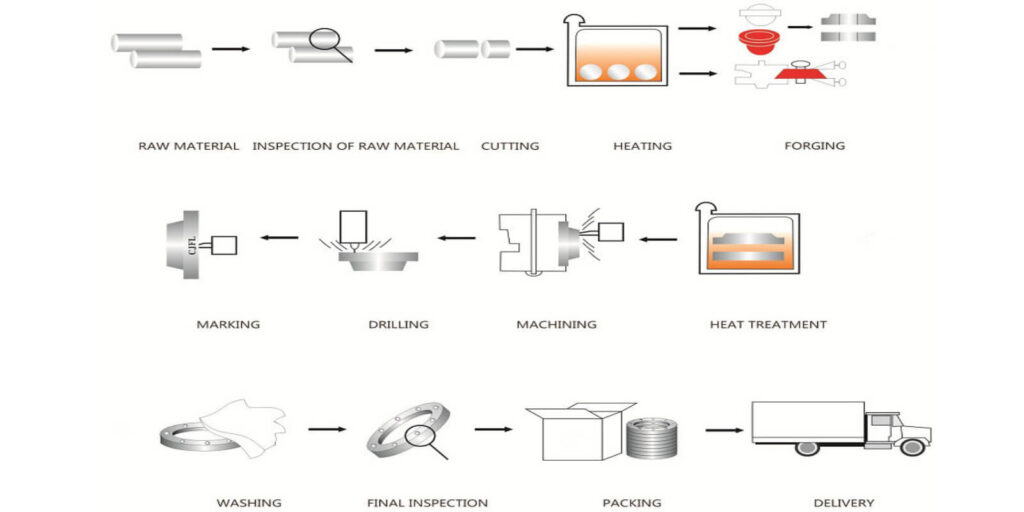

Our Manufacturing Process Of Hastelloy C276 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Hastelloy Flanges

Our Material

Contact Us

Supplying World Wide