Incoloy 800 Flanges

Home » Incoloy 800 Flanges

ASTM B564 Incoloy 800 Weld-Neck Flange-A-B, JIS NCF 800 Groove-Tongue Flange, UNS N08800 Weldo-Nipo Flange, UNS N08800 Swrf Flange, JIS NCF 800 Screwed Flange, JIS NCF 800 Orifice Flange, ASTM B564 Incoloy 800 Blind Flange, DIN 1.4876 Flat Flange, JIS NCF 800 Wnrf Flange, DIN 1.4876 Lap-Joint Flange.

Renine Metalloys LLP, a well-respected organization, takes pride in producing and providing a robust inventory of UNS N08800 Swrf Flange, known for its superior characteristics. Our Incoloy collection includes various specifications, standards, dimensions, sizes, and types. Aiming to accommodate global customers’ diverse needs, our offerings range from standard iterations to custom specifications.

Incoloy 800 is a unique blend of chromium, nickel, and iron. Its makeup includes the additional elements of copper, molybdenum, nitrogen, and silicon. Nestled within the 800 alloy family, Incoloy 800H and 800HT share the same chemical composition, with minor adjustments to aluminium, carbon, and titanium levels.

The DIN 1.4876 Flat Flange stands out for its superior resistance to oxidation, corrosion, carburization, and sulfidation. These extraordinary properties make the alloy an ideal candidate for flange production.

Our Incoloy 800 Flanges exhibit excellent weldability, workability, and formability properties. The flange’s robust chemical composition guarantees exceptional tensile strength even under extreme temperature and pressure conditions. Additionally, Incoloy 800 Flanges demonstrate high-stress rupture and creep-rupture capabilities for elevated temperatures. Utilizing standard manufacturing methods, our flanges can be fabricated and machined seamlessly.

At Renine Metalloys LLP, we carry out numerous destructive and non-destructive quality tests to ensure the high performance and durability of our Incoloy 800 Flanges. Our cadre of quality inspectors meticulously checks each flange parameter as part of a rigorous evaluation at multiple stages in the manufacturing process. Upon request, our Incoloy 800 Flanges can undergo third-party inspections as well. These assessments, conducted in our well-equipped facility utilizing cutting-edge automated tools, amplify our commitment to quality control.

Once the intensive testing phase is complete, our Incoloy 800 Flanges, free of defects and highly efficient, are carefully packaged using standard packaging techniques. We then ensure on-time and damage-free delivery using efficient transport methods, bolstering our commitment to superior customer service.

Specification Of Incoloy 800 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Incoloy 800 Flanges

-

JIS NCF 800 Nuts-Bolts Flange US $20 - $25 / Kg

-

DIN 1.4876 Flat Flange US $23 - $24 / Kg

-

ASTM B564 Incoloy 800 Forged Flange US $22 - $23 / Kg

-

UNS N08800 Forging Facing Flange US $24 - $25 / Kg

-

JIS NCF 800 Groove-Tongue Flange US $21 - $22 / Kg

Equivalent Grades Of Incoloy 800 Flanges

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | ЭИ670 | Z8NC32-21 | NCF 800 | NA 15 | X10NiCrAlTi32-20 | XH32T |

Chemical Composition Of Incoloy 800 Flanges

| Grade | Ni | Fe | Cr | Cu | Ti | Al | C | Mn | S | Si |

| Incoloy 800 | 30.0-35.0 | 39.5 min | 19.0-23.0 | .75 max | .15-.60 | .15-.60 | .1 max | 1.5 max | .015 max | 1.0 max |

Mechanical Properties Of Incoloy 800 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1350-1400 ℃ | Psi - 75,000 , MPa -520 | Psi - 30,000 , MPa - 205 | 30 - 35 % |

Different Types Of Incoloy 800 Flanges

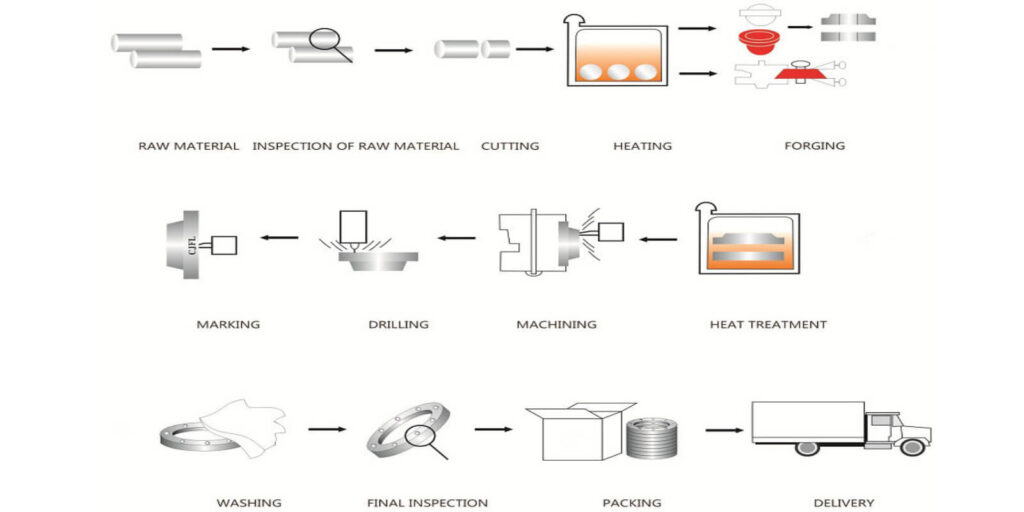

Our Manufacturing Process Of Incoloy 800 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Incoloy Flanges

Our Material

Contact Us

Supplying World Wide