Inconel 617 Flanges

Home » Inconel 617 Flanges

ASME SB564 Inconel 617 Slip-On Flange, UNS N06617 Forging Facing Flange, ASTM B564 Inconel 617 Ring-Type-Joint Flange, ASTM B564 Inconel 617 Weld-Neck Flange-A-B, ASME SB564 Inconel 617 Spectacle-Blind Flange, ASME SB564 Inconel 617 Reducing Flange, ASTM B564 Inconel 617 Socket-Weld Flange.

As a manufacturing powerhouse, Renine Metalloys LLP excels in producing superior-quality Inconel 617 Flanges, leveraging our reputation within the global enclave. We take pride in our diverse ASME SB564 Inconel 617 Reducing Flange, all fabricated with the utmost consideration for our client’s unique demands.

To ensure the excellence of our offerings, we rely on our state-of-the-art manufacturing facilities and rigorous testing procedures. We carefully source the best-grade raw materials to manufacture our high-end ASME SB564 Inconel 617 Slip-On Flange, choosing Inconel 617 as our core component. Thanks to its impressive features and inherent properties, this material contributes to a polished finished product suitable for high temperatures, high pressure, and other parameters. Consequently, our products receive high demand across multiple industries.

Partnering with authorized suppliers for raw material procurement, we conduct stringent diagnostic checks and sustainability tests. The approved raw material then enters the production phase. Our commitment to unsurpassed quality, distinctive finishes, and unique touches inform our analytical process, which envelops the raw materials and the finished product.

We at Renine Metalloys LLP offer an array of UNS N06617 Forging Facing Flange tailored to each customer’s specific requirements and operational conditions. Our knowledgeable experts ensure congruity with international product protocols and thoroughly inspect all product batches against authorized standards.

Our inventory warehouse securely stores our produced items in parallel with our production division. We pay diligent attention to each product throughout production and storage, using appropriate packaging to safeguard against rusting or damage during storage or transport. Our primary objective is to achieve customer satisfaction through product availability, effecting safe, flawless, and prompt deliveries to meet any urgent needs.

The ASTM B564 Inconel 617 Ring-Type-Joint Flange we produce are renowned for its resistance to various chemicals and mechanical parameters. Our seasoned specialists strive to ensure consistency in product quality, functionality, and superiority. With experienced staff and a top-tier infrastructure, we deliver products within the defined scope and receive professional insights to address challenges in the production process preemptively.

Specification Of Inconel 617 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Inconel 617 Flanges

-

ASME SB564 Inconel 617 Flat Flange US $44 - $50 / Kg

-

ASTM B564 Inconel 617 Forged Flange US $46 - $47 / Kg

-

UNS N06617 Forging Facing Flange US $44 - $46 / Kg

-

DIN 2.4663 Groove-Tongue Flange US $47 - $50 / Kg

-

ASME SB564 Inconel 617 Lap-Joint Flange US $45 - $49 / Kg

Equivalent Grades Of Inconel 617 Flanges

| STANDARD | UNS | WNR. |

| Alloy 617 | N06617 | 2.4663 |

Chemical Composition Of Inconel 617 Flanges

| C | Mn | S | Si | Cr | Mo | Ni | Cu | Ti | Al | B | Co | Fe |

| 0.05-0.15 | 1.0 Max | 0.015 Max | 1.0 Max | 20.0-24.0 | 8.0-10.0 | 44.5 Min | 0.5 Max | 0.6 Max | 0.8-1.5 | 0.006 Max | 10.0-15.0 | 3.0 Max |

Mechanical Properties Of Inconel 617 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Different Types Of Inconel 617 Flanges

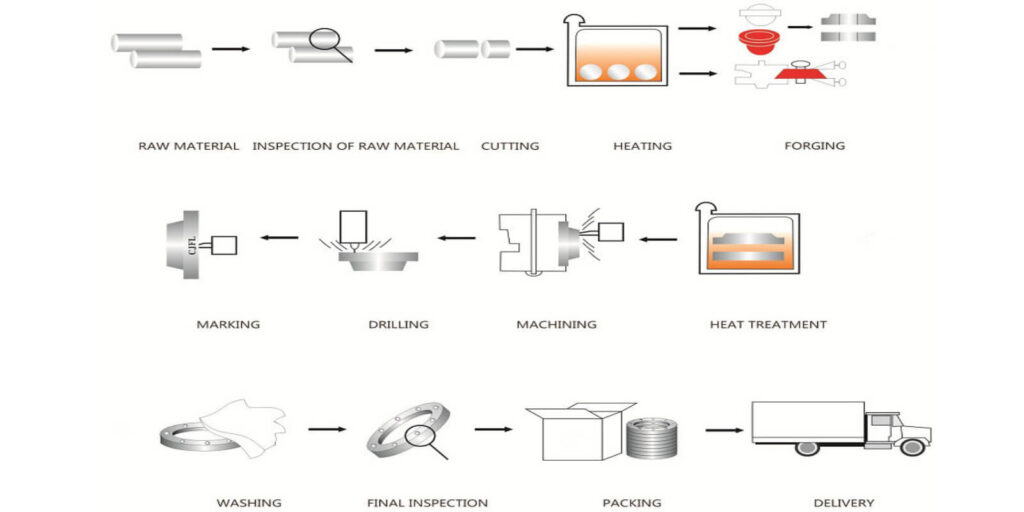

Our Manufacturing Process Of Inconel 617 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Flanges

Our Material

Contact Us

Supplying World Wide